Intelligent power module and manufacturing method thereof

A technology of intelligent power module and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as ignoring packaging methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

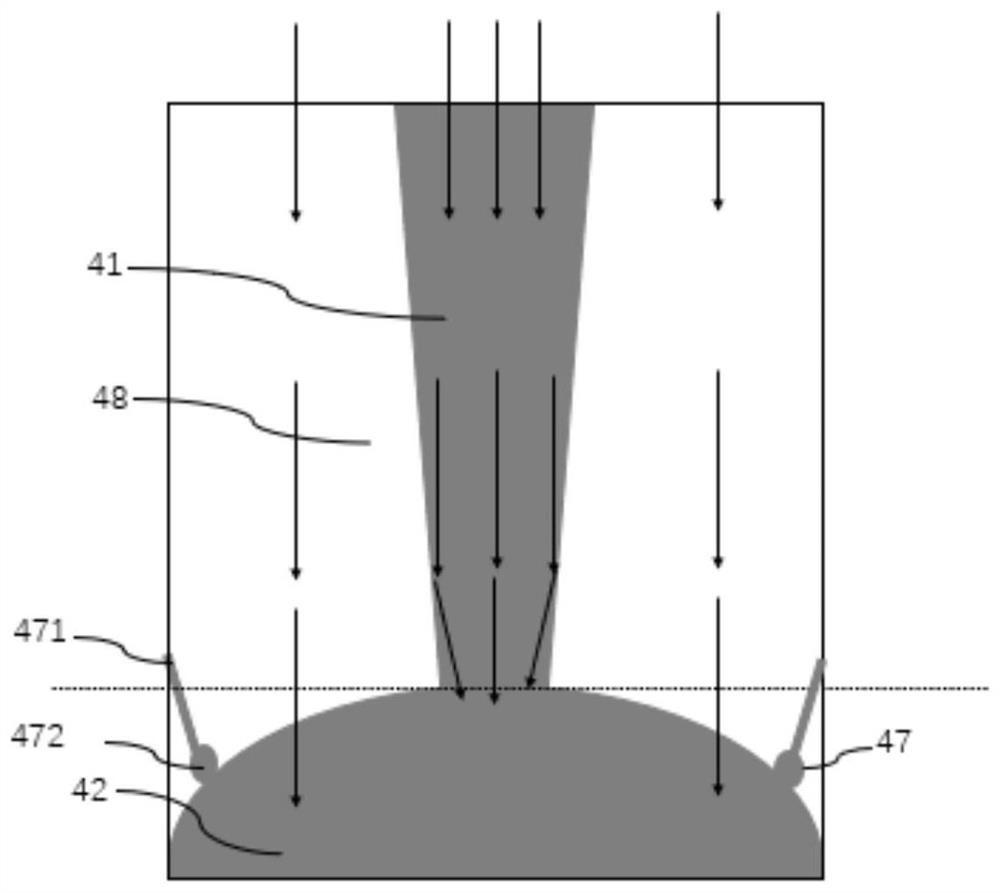

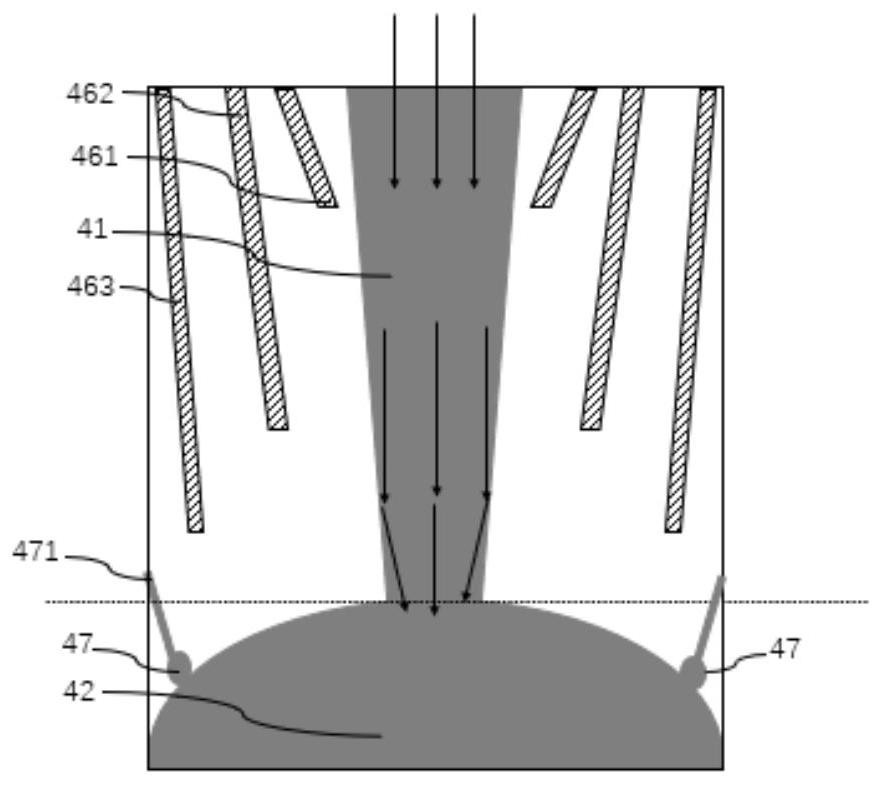

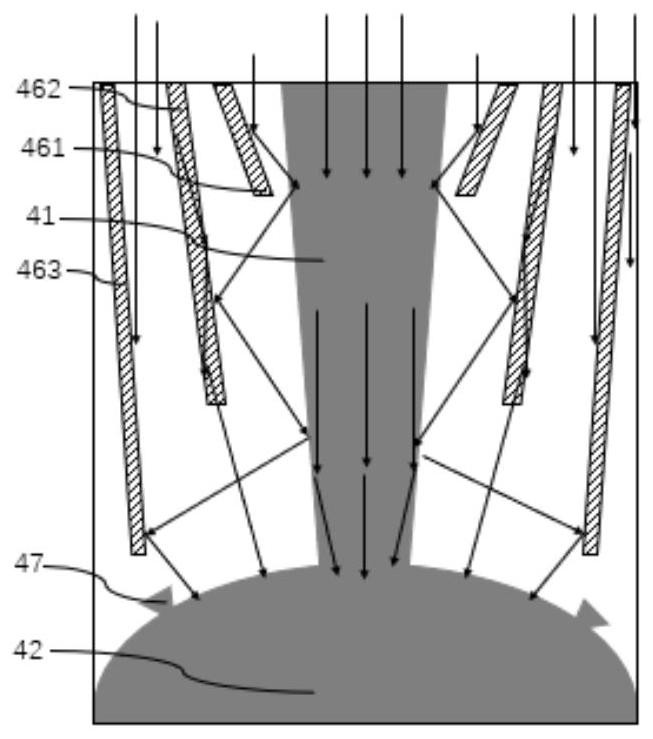

[0041] A detailed description will be given below in conjunction with the accompanying drawings.

[0042] Aiming at the cumbersome process of curing the photosensitive glue in the packaging process of the intelligent power module in the prior art, the present invention improves the structure of the light-transmitting component and the injection method of the photosensitive glue, so that the photosensitive glue can be cured faster and can be combined with the light-transmitting The components are removed in a connected manner, which reduces the retention probability of the photosensitive adhesive, optimizes the packaging method of the intelligent power module, improves the packaging speed, and then improves the packaging efficiency.

[0043] The substrate in the present invention is a printed circuit board, a ceramic substrate or a semiconductor interposer, wherein appropriate circuits and / or plated through holes (not shown) are provided in the substrate to electrically connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com