Efficient solid-liquid separation device

A solid-liquid separation and high-efficiency technology, which is applied in the direction of separation method, sedimentation separation, feeding/discharging device of settling tank, etc., can solve the problems of reducing the overall recovery rate of products, complex components of coking wastewater, high content of miscellaneous salts, etc., to achieve Reasonable design structure, reduced processing costs, and high-efficiency separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

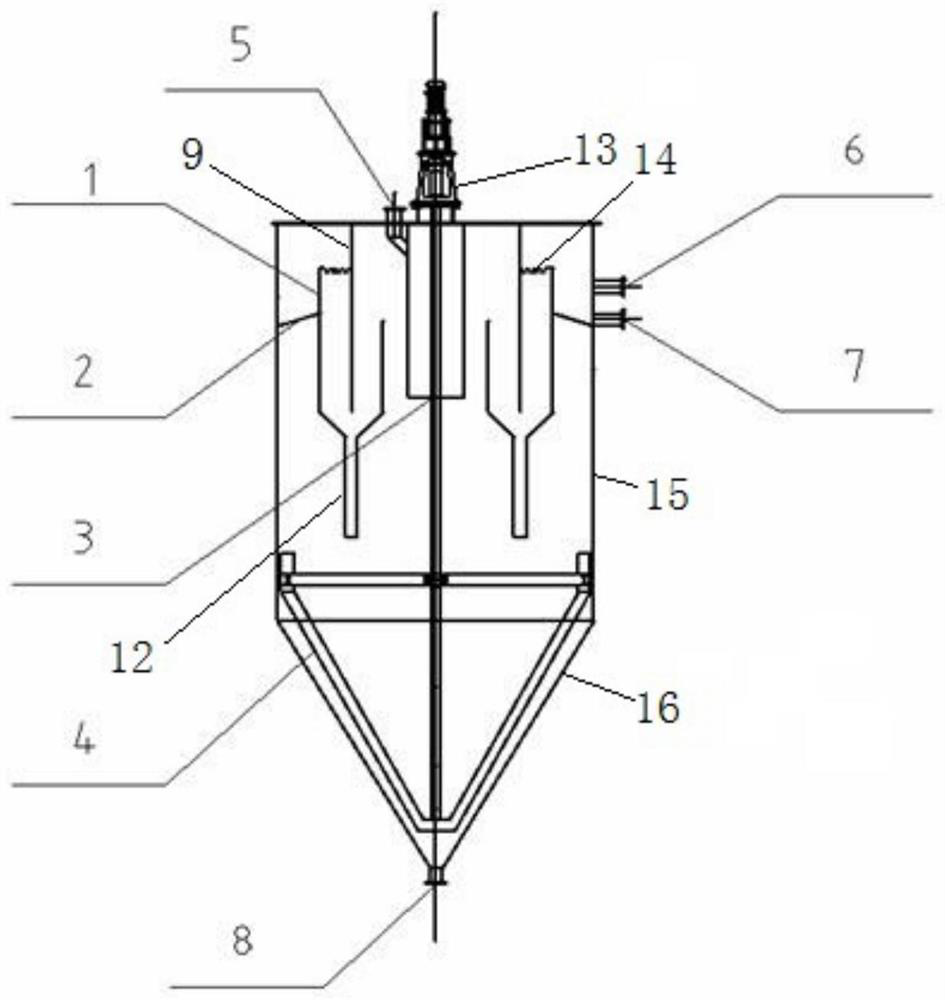

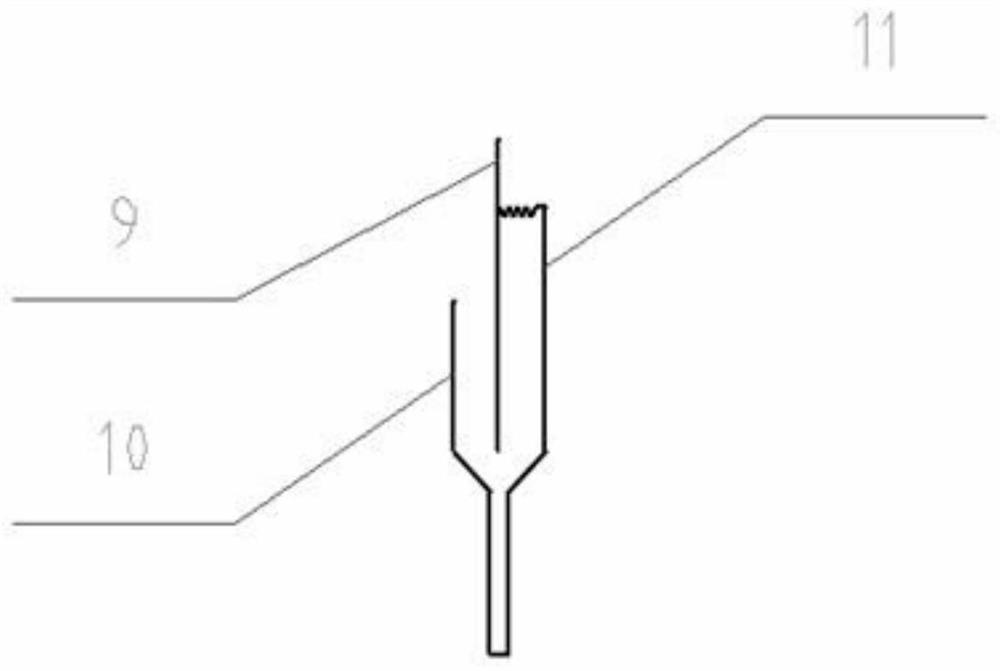

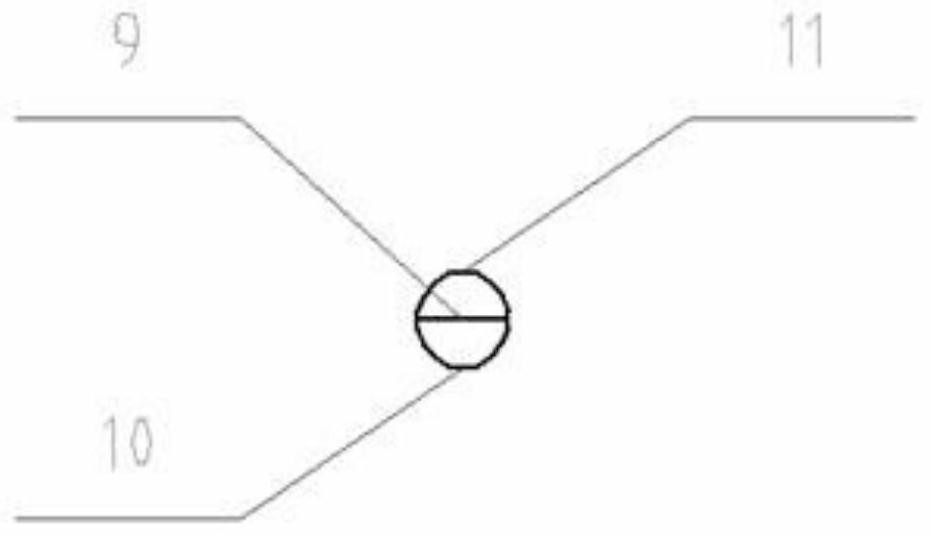

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 A kind of high-efficiency solid-liquid separation device shown comprises circular cylinder 15, and the conical discharge shell 16 that is arranged on one side of circular cylinder 15, and is arranged on circular cylinder 15, conical discharge shell respectively. The solid outlet 8 on the 16, the feed port 5, and the guide tube 3 that is arranged on the inner wall of the upper part of the circular cylinder 15 and is used in conjunction with the feed port 5, and is arranged on the inner wall of the upper part of the circular cylinder 15 and is located in the guide tube. A plurality of vertical partitions 9 on the outer layer of the flow tube 3, overflow teeth 14 respectively connected to the vertical partitions 9, and hoppers 1 respectively connected to the overflow teeth 14, and solid settling tubes respectively arranged on the bottom surface of the hopper 1 12, and the overflow port 6 and the liquid delivery port ...

Embodiment 2

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 A kind of high-efficiency solid-liquid separation device shown comprises circular cylinder 15, and the conical discharge shell 16 that is arranged on one side of circular cylinder 15, and is arranged on circular cylinder 15, conical discharge shell respectively. The solid outlet 8 on the 16, the feed port 5, and the guide tube 3 that is arranged on the inner wall of the upper part of the circular cylinder 15 and is used in conjunction with the feed port 5, and is arranged on the inner wall of the upper part of the circular cylinder 15 and is located in the guide tube. A plurality of vertical partitions 9 on the outer layer of the flow tube 3, overflow teeth 14 respectively connected to the vertical partitions 9, and hoppers 1 respectively connected to the overflow teeth 14, and solid settling tubes respectively arranged on the bottom surface of the hopper 1 12, and the overflow port 6 and the liquid outlet 7 arran...

Embodiment 3

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 A kind of high-efficiency solid-liquid separation device shown comprises circular cylinder 15, and the conical discharge shell 16 that is arranged on one side of circular cylinder 15, and is arranged on circular cylinder 15, conical discharge shell respectively. The solid outlet 8 on the 16, the feed port 5, and the guide tube 3 that is arranged on the inner wall of the upper part of the circular cylinder 15 and is used in conjunction with the feed port 5, and is arranged on the inner wall of the upper part of the circular cylinder 15 and is located in the guide tube. A plurality of vertical partitions 9 on the outer layer of the flow tube 3, overflow teeth 14 respectively connected to the vertical partitions 9, and hoppers 1 respectively connected to the overflow teeth 14, and solid settling tubes respectively arranged on the bottom surface of the hopper 1 12, and the overflow port 6 and the liquid outlet 7 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com