Preparation method and application of tea seed shell biochar

A tea seed husk and biochar technology, which is applied in the field of heavy metal pollution control and repair, can solve the problems of increased cost and production difficulty, increased cost of biochar, loss of agricultural resources, etc., and achieves good application prospects, easy implementation, and simple use method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

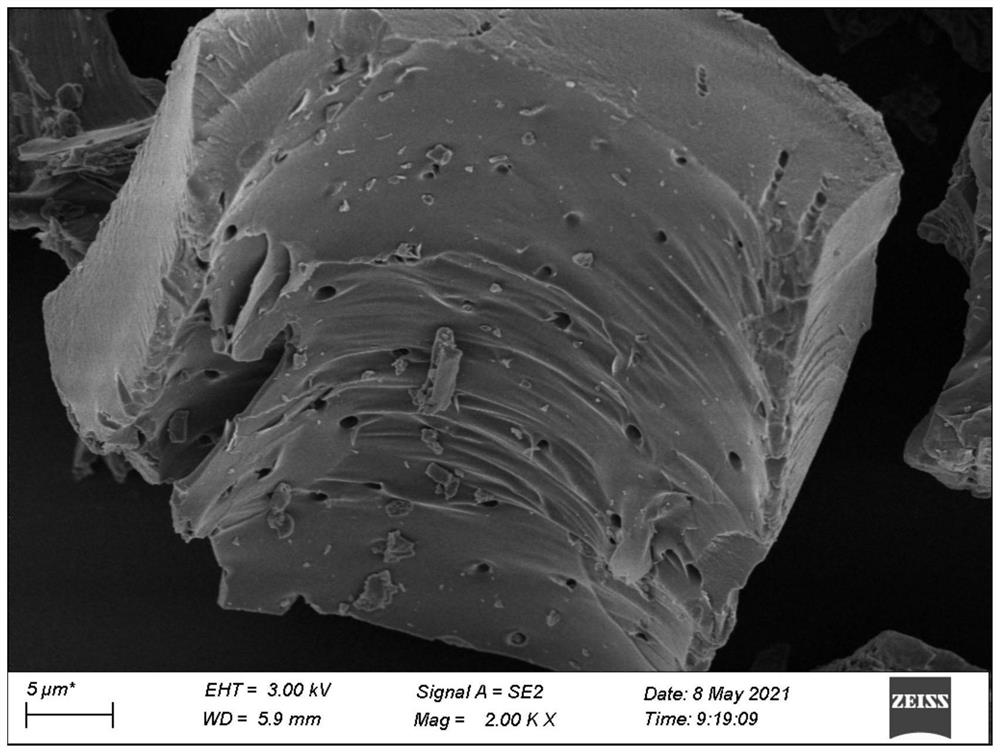

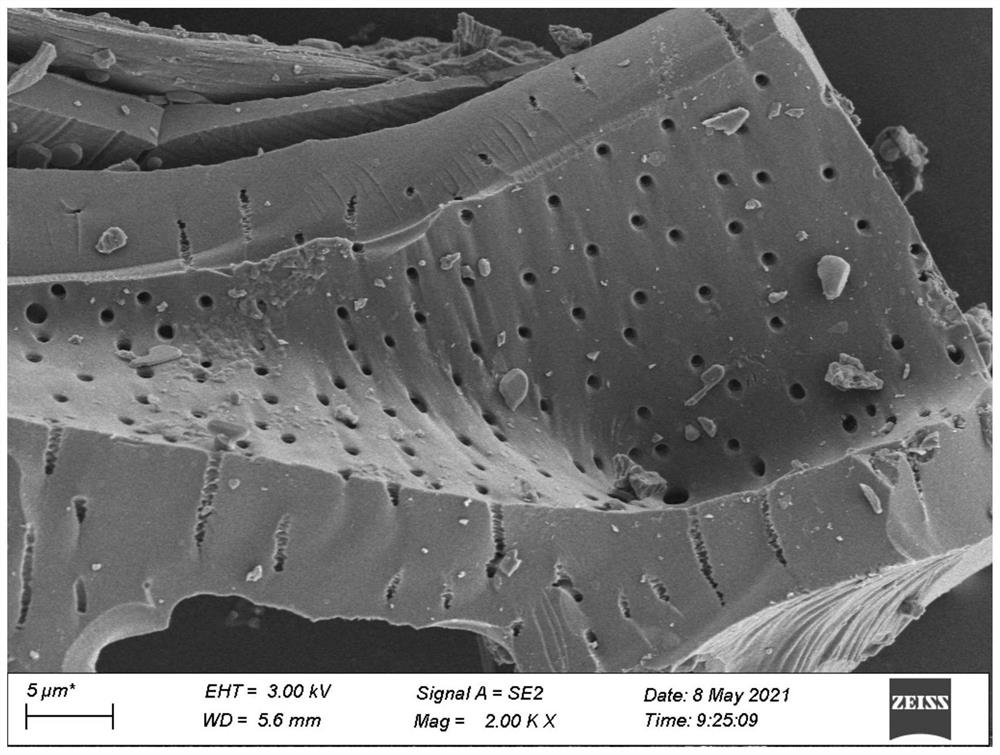

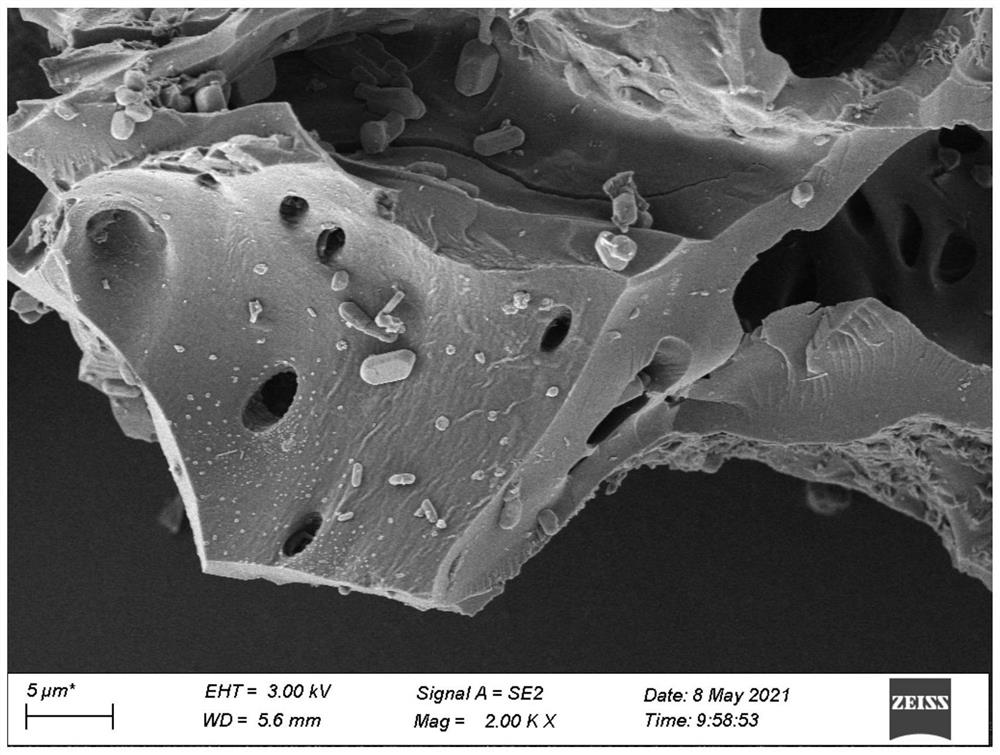

[0023] (1) Preparation method

[0024] Tea seed husks were washed, dried and pulverized, and the debris was put into a tube furnace, and the firing temperatures were set at 300°C, 450°C and 600°C, respectively, and N 2 The flow rate is controlled at 80-120mL / min, the heating rate is 10°C / min, N 2 Burn at constant temperature and temperature for 6 hours in an oxygen-limited environment, cool to room temperature after firing, take out the biochar, and pass the biochar through a 100-mesh sieve to obtain tea seed shell biochar, whose particle size is less than 0.150 mm, corresponding to The numbers are C300, C450 and C600 respectively.

[0025] (2) Characterization parameters of biochar-related materials

[0026] With the increase of pyrolysis temperature for biochar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com