Modified PBAT granulation device and preparation method of PBAT foaming material

A granulation device and modification technology, applied in chemical instruments and methods, solid separation, metal processing, etc., can solve the problems of affecting the conveyance, clogging of sieve plates, wet raw materials, etc., so as to improve the granulation efficiency and work. Efficiency, improved ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

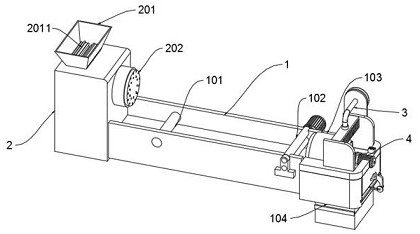

[0103] as attached figure 1 to attach Figure 14 Shown:

[0104] The invention provides a modified PBAT granulation device and a method for preparing foamed materials thereof, including a cooling plate rail 1;

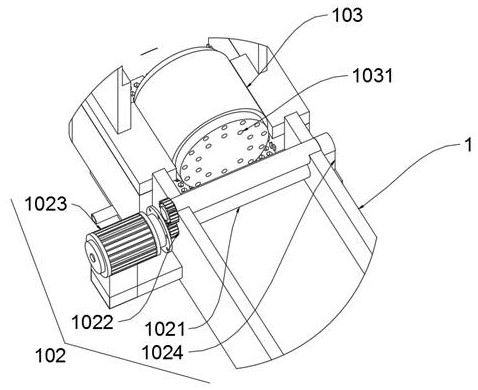

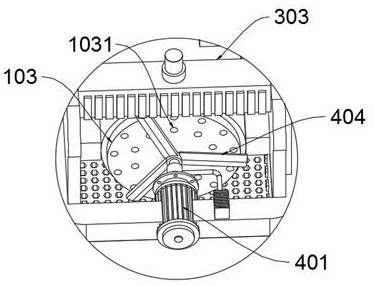

[0105] There is a groove in the middle of the cooling plate rail 1 and built-in cooling water, a guide roller 101 is provided at the left end of the cooling plate rail 1, a driving roller assembly 102 is provided at the right end of the cooling plate rail 1, and a driving roller assembly 102 is fixedly installed at the right end of the cooling plate rail 1. The guide seat 103 is provided with a guide hole 1031, the right end of the cooling plate rail 1 is a side bracket 104, and the bottom end of the side bracket 104 is a sieve plate 105, and the left end of the cooling plate rail 1 is a Extruder 2;

[0106] A drying device 3 is installed on the side support 104, a pelletizing device 4 is installed on the right end of the side support 104, a reciprocating device 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com