Steaming and boiling-resistant multi-layer composite aluminum-foil paper and production method thereof

A multi-layer composite and production method technology, which is applied in the field of aluminum foil materials, can solve problems such as the settlement of reinforced parts, the insignificant improvement in the structural strength of aluminum foil composite paper, and the inability to dry both sides together, achieving moderate difficulty in disassembly and maintenance, and low drying temperature. Flexible and adjustable, high internal structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

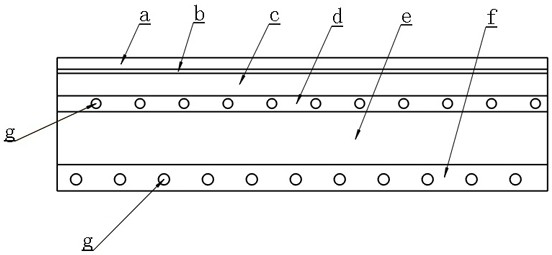

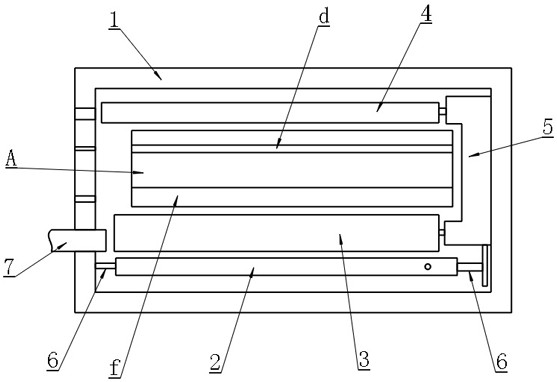

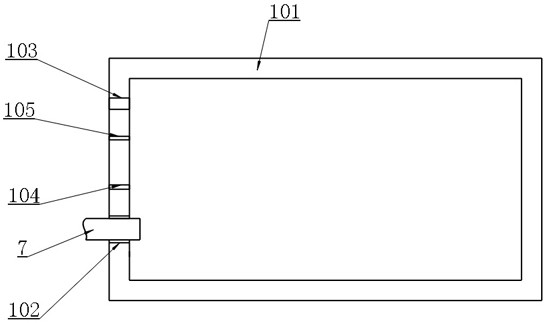

[0031] Example: as attached Figure 1-7 As shown, a retort-resistant multi-layer composite aluminum foil paper includes a waterproof film layer a, a first adhesive layer b, a cardboard layer c, a second adhesive layer d, an aluminum foil layer e and a resin layer f from outside to inside , both the second adhesive layer d and the resin layer f are provided with structural reinforcing strips g.

[0032] In this embodiment, the material of the waterproof film layer a is polyethylene, the first adhesive layer b and the second adhesive layer d are composed of common glass glue or 602 nitrile glue, and the cardboard layer c It is a common printing paper, and the material of the resin layer f is PP coating resin, which has high food safety and meets the requirements of microwave oven heating. Finally, the material of the structural reinforcement bar g is the existing common Lightweight aluminum ensures that the lunch box made of the multi-layer composite aluminum foil paper has suf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com