Three-section biological rotating disc sewage treatment device

A technology of sewage treatment device and biological turntable, which is applied in the fields of biological treatment device, biological water/sewage treatment, sustainable biological treatment, etc. It can solve the problems of heavy transformation tasks and other problems, so as to increase the stress relief process of post-weld heat treatment, reduce the amount of swing, and enhance the safety and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

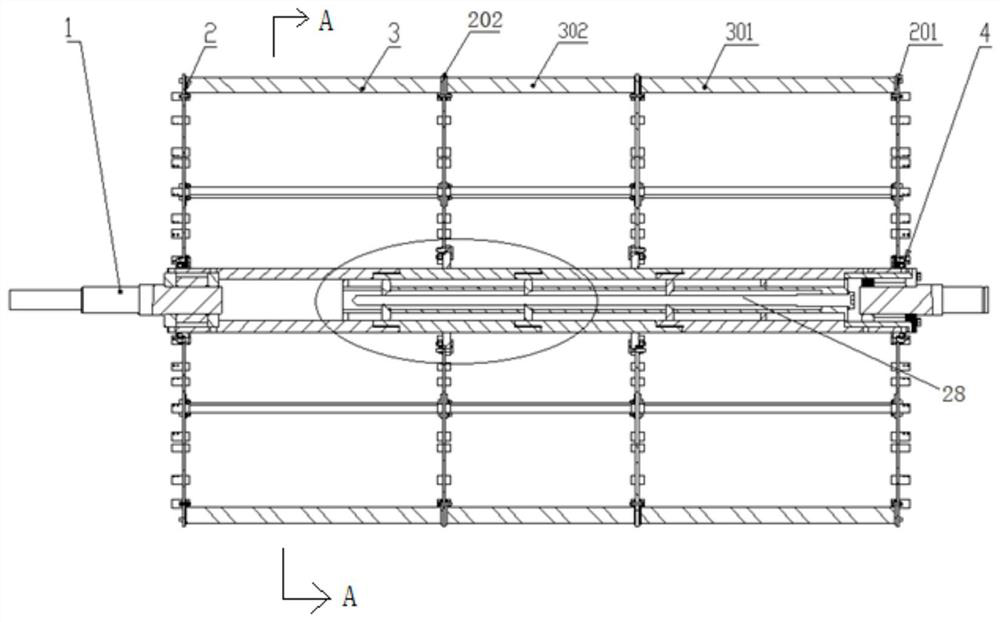

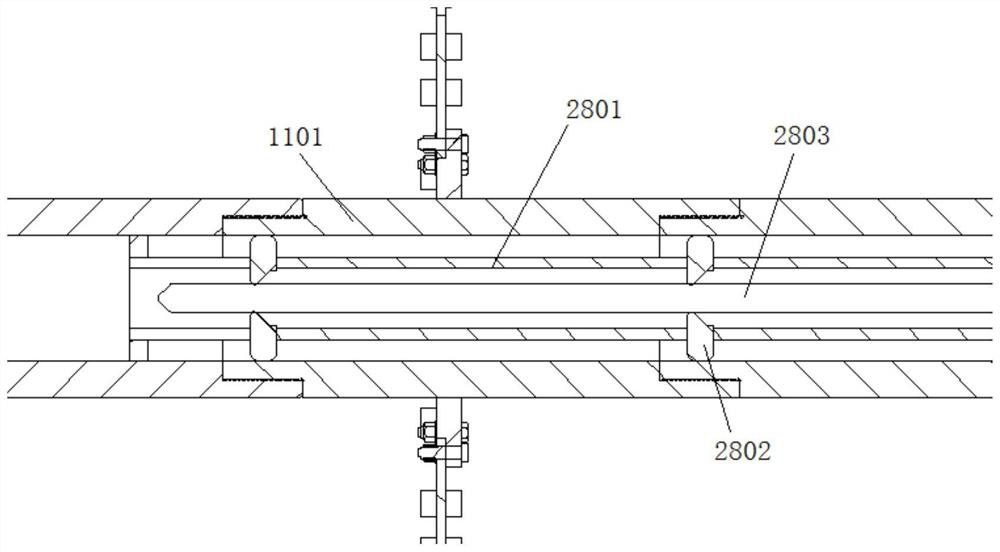

[0057] The three-stage biological turntable sewage treatment device described in this embodiment includes a rotating shaft 1, a rotating disk 2 and several pieces of biological contact bodies 15, and the biological contact bodies 15 are fixed on the rotating shaft 1 through the rotating disk 2;

[0058] The turntable 2 is arranged concentrically with the rotating shaft 1, and the turntable 2 includes two outer turntables 201 and two inner turntables 202, the two outer turntables 201 are respectively fixed on the two ends of the turn shaft 1, and the two inner turntables 202 are evenly spaced. , detachably arranged in the middle of the rotating shaft 1;

[0059] The biological contact body 15 is arranged between the outer turntable 201 and the inner turntable 202 and between two inner turntables 202, and the biological contact body 15 is arranged concentrically with the rotating shaft 1;

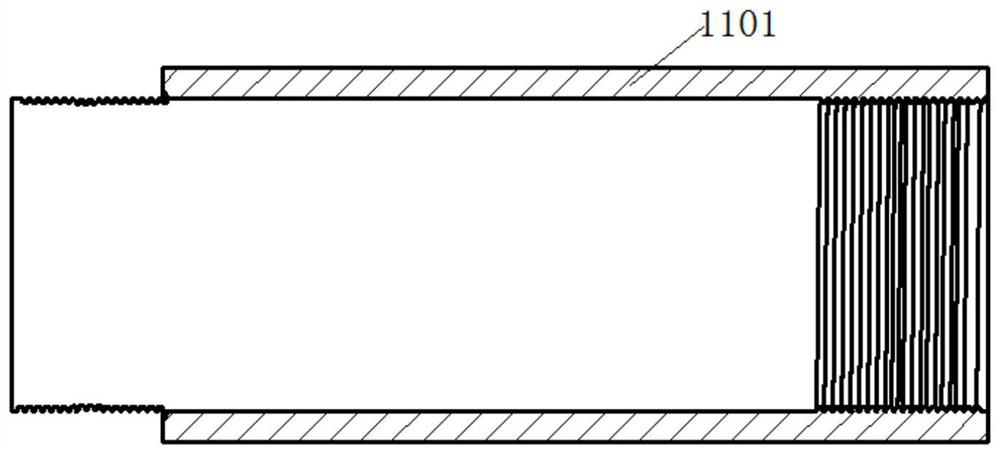

[0060] The rotating shaft 1 includes a driving shaft head 9, a driven shaft head 10 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com