Premixed mortar and application thereof

A technology of ready-mixed mortar and recycled aggregate, which is applied in the field of ready-mixed mortar, can solve problems such as not being well recognized, and achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

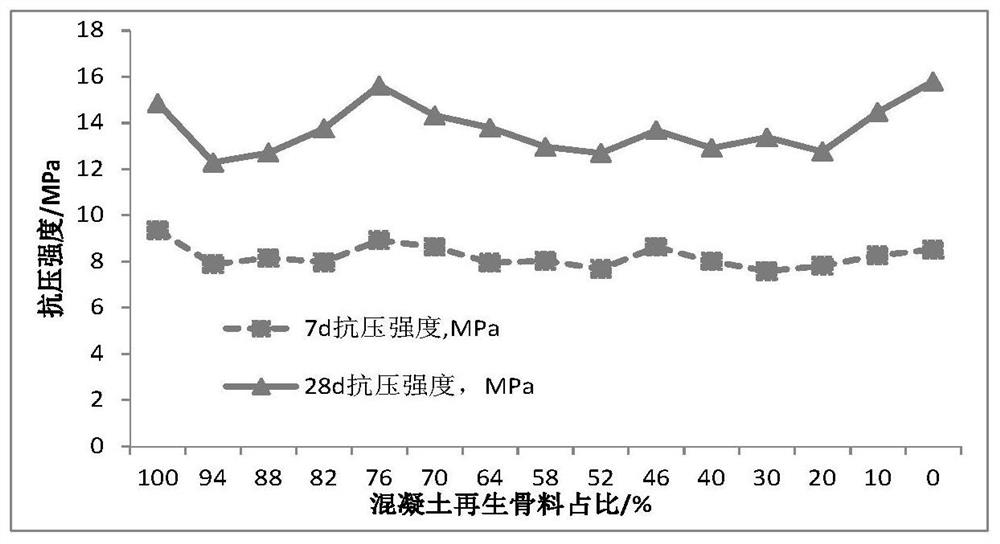

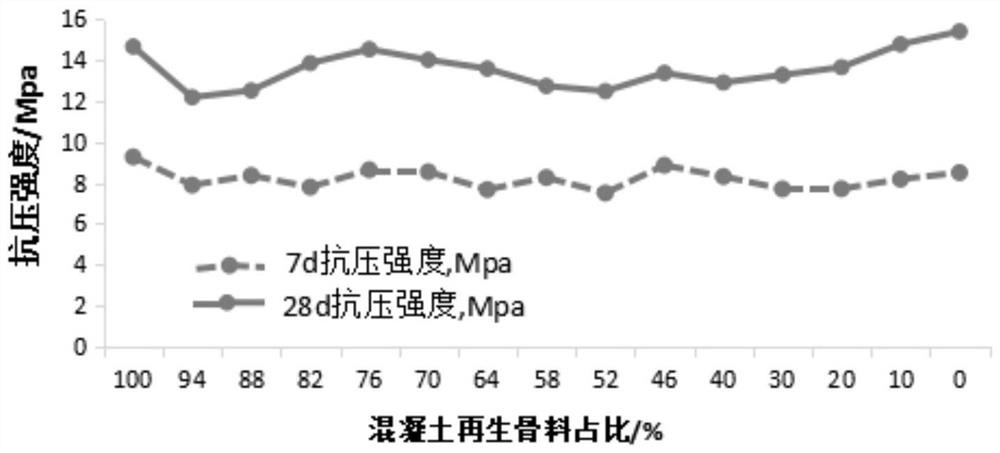

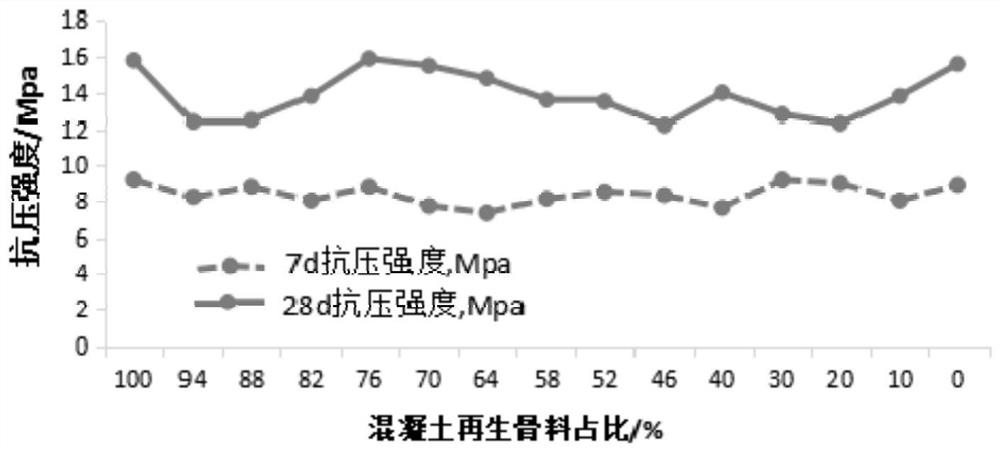

Image

Examples

Embodiment 1

[0024] The premisted mortar in this embodiment includes a material and auxiliary material, wherein the material comprises the following material by weight fraction: 14% of silicate cement, 16% of secondary fly ash, concrete regeneration aggregate and red brick regeneration The total amount of aggregate, concrete regenerated aggregate and red brick regenerated aggregate was 70%, and the regenerated aggregate particle diameter was 5 to 10 mm. According to the total weight fraction of the ready-mixed mortar, the excipient comprises: 0.02% water storage agent, 0.025% water reduction agent, 0.01% polyvinyl alcohol, and the regenerated aggregate is prepared by high temperature calcination cooling, the high temperature. The calcination temperature was 1330 ° C, and the calcination time was 80 min.

Embodiment 2

[0026] The premisted mortar in this embodiment includes a material and auxiliary material, wherein the material comprises the following materials by weight fraction: silicate cement is 15%, secondary fly ash 17%, concrete regeneration aggregate and red bricks Regenerated aggregate, concrete regenerated aggregate and red brick regenerated aggregate aggregate amount of 68%, the regenerated aggregate particle diameter of 5 to 10 mm. According to the total weight fraction of the ready-mixed mortar, the excipient comprises: 0.02% water storage agent, 0.025% water reduction agent, 0.01% polyvinyl alcohol, and the regenerated aggregate is prepared by high temperature calcination cooling, the high temperature. The calcination temperature was 1330 ° C, and the calcination time was 80 min.

Embodiment 3

[0028] The premisted mortar in this embodiment includes a material and auxiliary material, wherein the material comprises the following material by weight fraction: silicate cement is 17%, secondary fly ash 12%, concrete regeneration aggregate and red bricks Regenerated aggregate, concrete regenerated aggregate and red brick regenerated aggregate aggregate aggregate, the regenerated aggregate particle diameter of 5 to 10 mm. According to the total weight fraction of the ready-mixed mortar, the excipient comprises: 0.02% water storage agent, 0.025% water reduction agent, 0.01% polyvinyl alcohol, and the regenerated aggregate is prepared by high temperature calcination cooling, the high temperature. The calcination temperature was 1330 ° C, and the calcination time was 80 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com