Environment-friendly anhydrous cooling liquid as well as preparation method and application thereof

An environment-friendly, water-cooled technology, which is applied in the field of coolant, can solve the problems of limited service life and easy formation of scale in the coolant after long-term use, so as to achieve the effect of prolonging service life, good protection, and ensuring long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The second aspect of the present disclosure provides the method for preparing the anhydrous cooling liquid described in the first aspect, wherein the method includes the following steps: mixing the metal corrosion inhibitor, fluorinated liquid, dispersant and antifreeze according to the proportion, Stir once; add the acid-base regulator and stir twice; add the defoamer and stir three times.

[0029] According to the present disclosure, the conditions for the primary stirring include: the stirring temperature is 58-60°C, and the stirring time is 30-45min; the conditions for the secondary stirring include: the stirring temperature is 58-60°C, and the stirring time is 30 minutes. -40 min; the conditions for the three stirrings include: the stirring temperature is 58-60° C., and the stirring time is 10-20 min.

[0030] The third aspect of the present disclosure provides the application of the water-free coolant in the first aspect in a heavy-duty LNG engine.

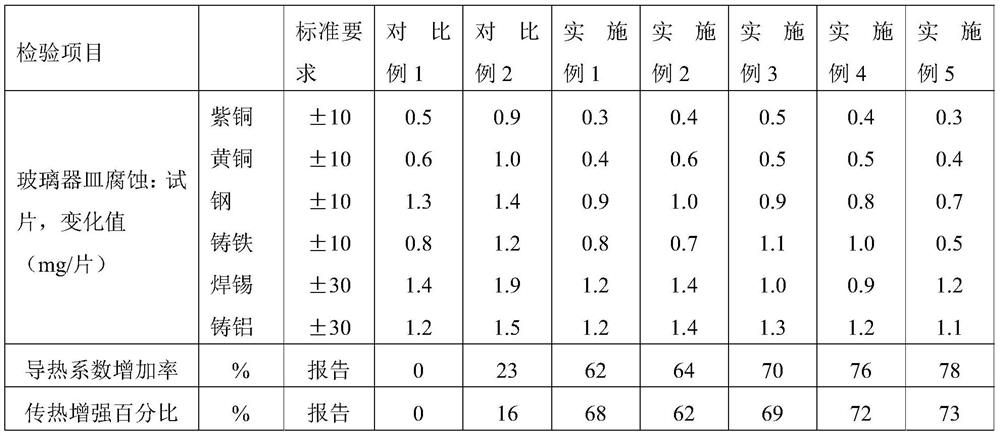

[0031] The e...

Embodiment 1

[0040] The present embodiment prepares a kind of environmentally friendly coolant (total mass 100kg) according to the following method:

[0041]1 weight part of metal corrosion inhibitor (0.4 weight part of 2-hexyl-1-(ethoxypropionic acid)-imidazoline, 0.2 weight part of 2,4-dihydroxybenzoic acid, 0.4 weight part of petroleum sulfonic acid acid sodium), 0.3 parts by weight of fluorinated liquid (0.5 parts by weight of 3M Novec HFE-7100), 0.3 parts by weight of dispersant (0.15 parts by weight of aminotrimethylene phosphonic acid and 0.15 parts by weight of hydroxyethylene di Phosphonic acid (tetra) sodium), 90 parts by weight of antifreeze (propylene glycol of 45 parts by weight and ethylene glycol of 45 parts by weight) were uniformly mixed, stirred at 60°C for 35min, and the stirring frequency was 600rpm; adding 0.26 parts by weight of acid Alkali conditioner (sodium hydroxide), stirring for 30 minutes, stirring frequency is 600 rpm; then add 0.01 weight part of antifoaming ...

Embodiment 2

[0043] The present embodiment prepares a kind of environmentally friendly coolant (total mass 100kg) according to the following method:

[0044] 6 parts by weight of metal corrosion inhibitor (2-hexyl-1-(ethoxypropionic acid)-imidazoline of 2 parts by weight, 2,4-dihydroxybenzoic acid of 1.8 parts by weight and petroleum sulfonic acid of 2.2 parts by weight Sodium acid), 1 part by weight of fluorinated liquid (3M Novec HFE-7100), 2 parts by weight of dispersant (1 part by weight of aminotrimethylene phosphonic acid and 1 part by weight of hydroxyethylene diphosphonic acid (tetrafluoroethylene diphosphonic acid) ) sodium), 100 parts by weight of antifreeze (propylene glycol of 45 parts by weight and ethylene glycol of 55 parts by weight) are uniformly mixed, stirred at 60° C. for 35 min, and the stirring frequency is 600 rpm; adding 0.9 parts by weight of an acid-base regulator ( sodium hydroxide), stirred for 30 min, and the stirring frequency was 600 rpm; then 4 parts by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com