Condensate water recovery system for high-quality steel preparation

A recovery system and condensed water technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as chaotic condensed water circulation, difficult discharge of condensed water, high pressure of condensed water, etc., to achieve smooth flow of condensed water, The effect of preventing excessive temperature and excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 1-Figure 5 Shown:

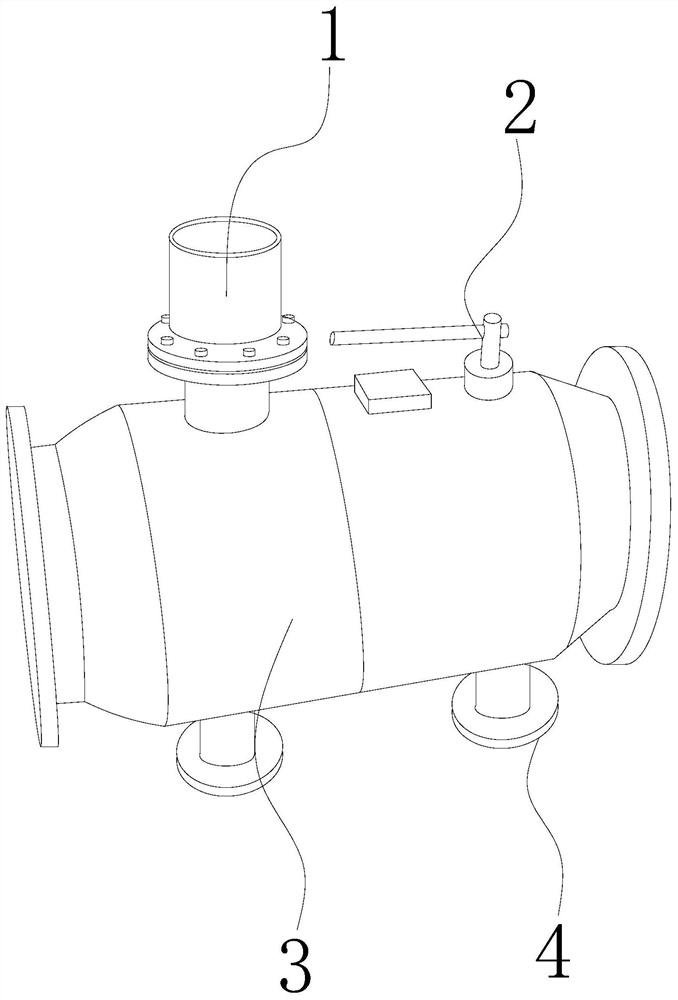

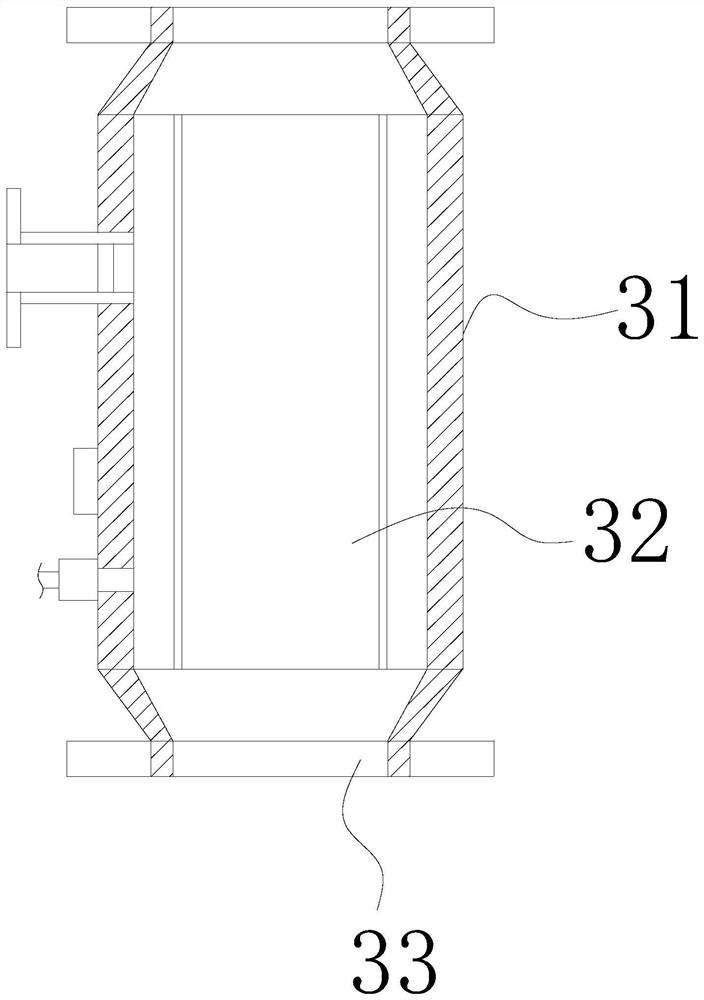

[0027] The present invention is a condensed water recovery system for the preparation of high-quality steel products. Its structure includes a limit nozzle 1, a switch handle 2, a recovery mechanism 3, and a fixed column 4. The limit nozzle 1 is embedded in the upper end of the recovery mechanism 3. The fixed column 4 is welded on the lower end of the recovery mechanism 3, the switch handle 2 is installed on the upper end of the recovery mechanism 3, the recovery mechanism 3 is provided with a recovery pipe 31, a rotating structure 32, and a joint 33, and the rotating structure 32 is embedded in the recovery mechanism 3. Inside the pipe 31, the joint 33 is installed on the upper and lower ends of the recovery pipe 31, the rotating structure 32 and the joint 33 are located on the same central axis, the limit nozzle 1 runs through the side of the recovery pipe 31, and the middle of the joint 33 The diameter of the pipeline is slightly ...

Embodiment 2

[0034] Such as Figure 6-Figure 8 Shown:

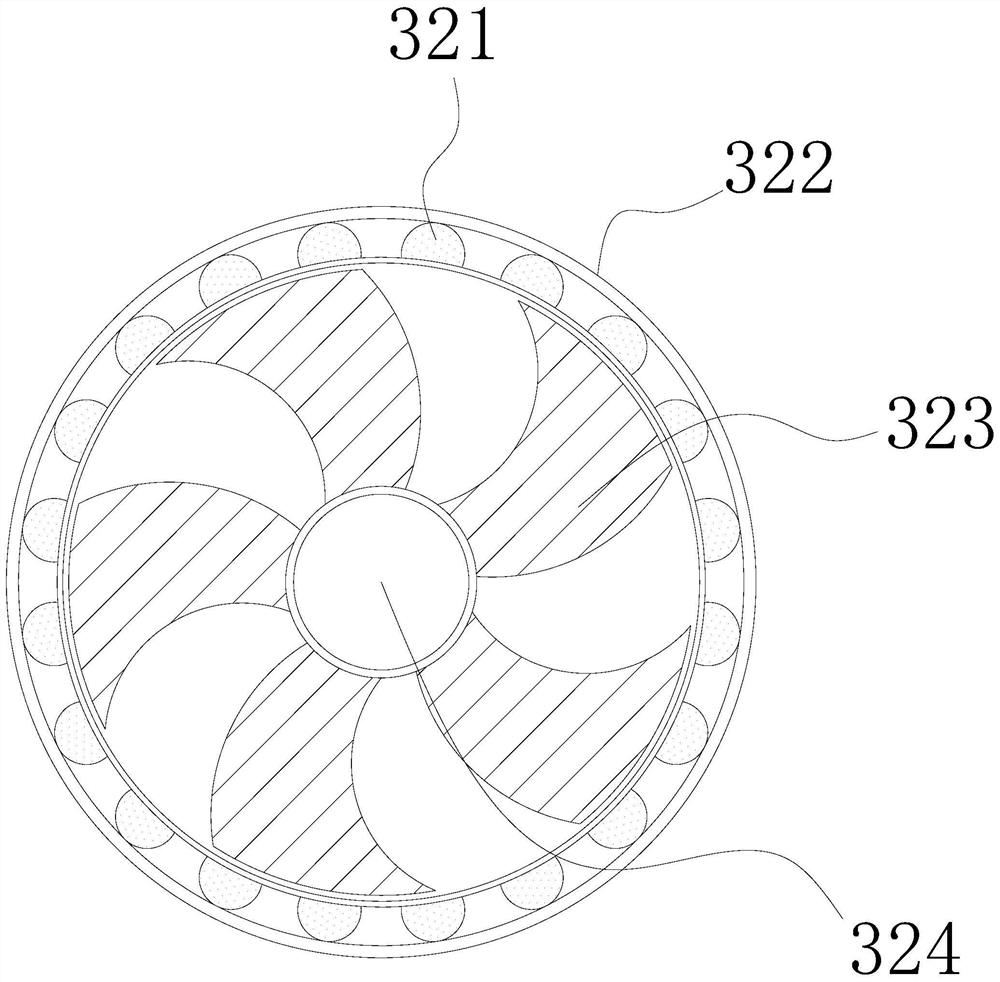

[0035]Wherein, the stressed structure 323 is provided with an extrusion structure w1, a support plate w2, and a guide plate w3, the lower end of the extrusion structure w1 is embedded in the upper end of the support plate w2, and the left and right sides of the upper end of the extrusion structure w1 are bonded together. On the inner side of the guide plate w3, the lower end of the guide plate w3 is engaged with the upper end of the support plate w2, and the support plate w2 is installed on the outside of the rotating shaft 324. The guide plate w3 is made of aluminum alloy, which has strong toughness and is easy to bend. Thus, the condensed water impacts the extruded structure w1 on the upper end of the support plate w2, so that the condensed water is extruded and guided on the surface of the extruded structure w1, so that the extruded structure w1 blocks the condensed water and at the same time drives the rotating shaft 324 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com