Engine crankshaft gyroscopic moment testing device and testing method

A technology of crankshaft rotation and testing equipment, which is applied in the direction of engine testing, measuring equipment, and testing of machine/structural components. It can solve problems such as abnormal resistance, damage to the crankshaft and upper and lower bearing bushes of the crankshaft, and high equipment costs, so as to avoid rework and reduce High maintenance cost and high maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

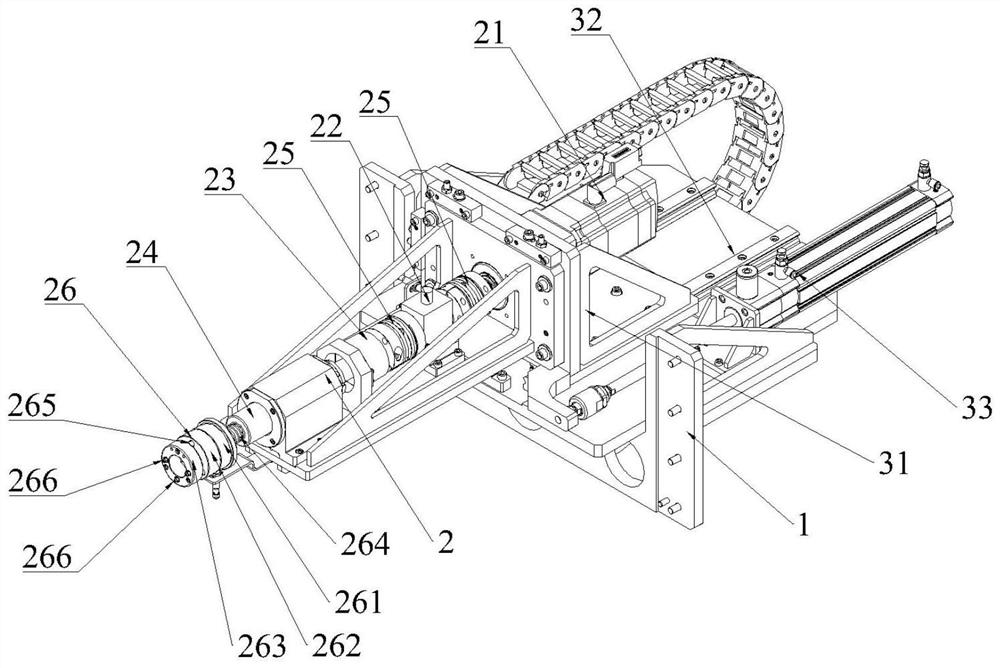

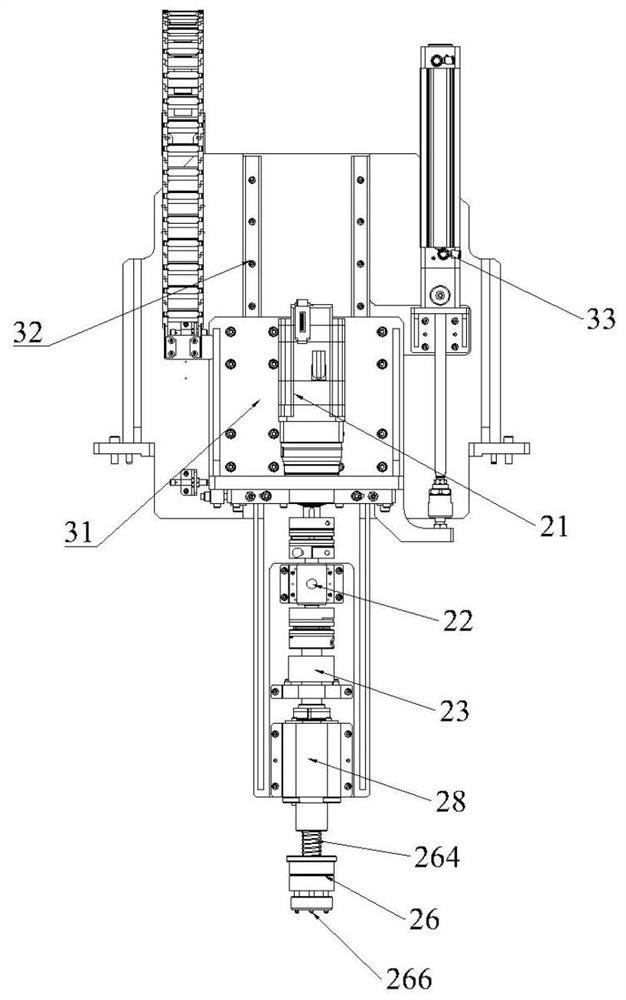

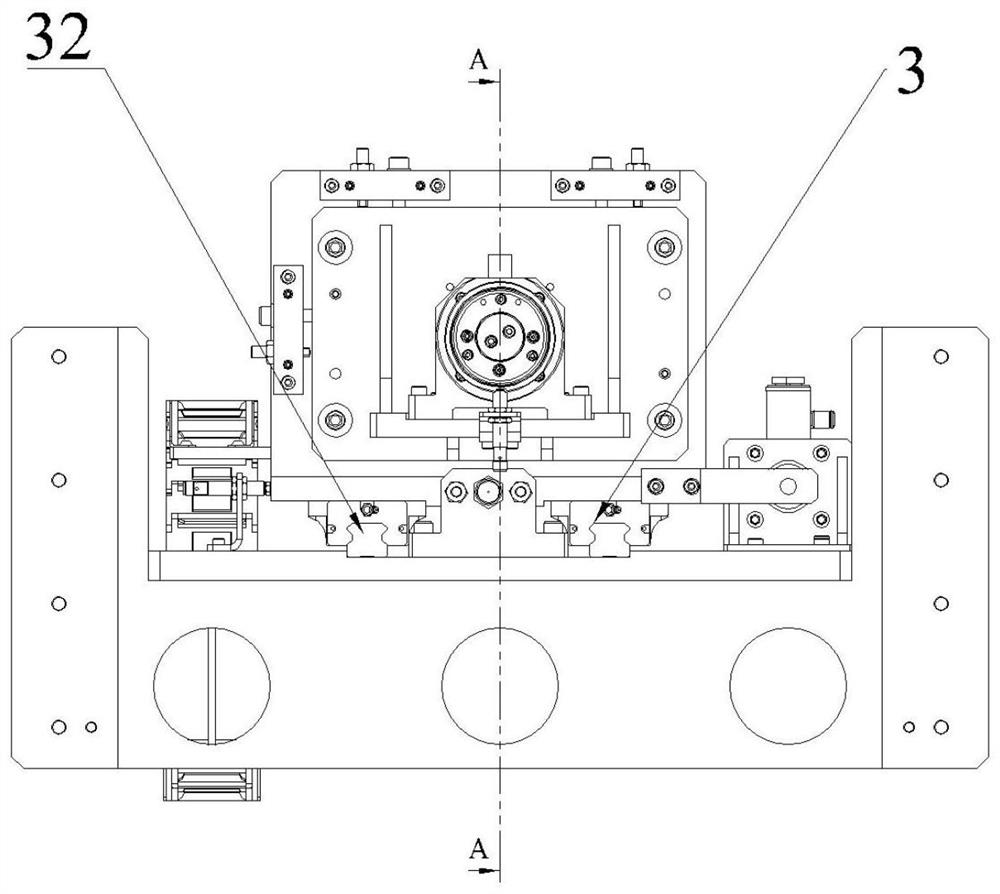

[0060] refer to Figure 1-Figure 4 The present invention provides an engine crankshaft rotation torque testing device, which includes a frame 1, a torque detection device 2 and a control system, and the torque detection device 2 is slidably arranged on the frame 1 along the direction of docking with the engine. The torque detection device 2 is slidably connected to the frame 1 through a horizontal moving device 3, and the horizontal moving device 3 includes a sliding seat 31, a guiding device 32 arranged at the bottom of the sliding seat 31, and drives the sliding seat 31 horizontally. A moving drive device 33; the torque detection device 2 is arranged on the sliding seat 31, driven by the drive device 33, the torque detection device 2 can move horizontally along the direction of docking with the engine;

[0061] The torque detection device 2 includes a drive motor 21, a torque detection device 22, a rotational speed detection device 23, a transmission shaft 24 and a crankshaf...

Embodiment 2

[0076] The present invention also provides a rotational torque testing method of the above-mentioned engine crankshaft rotational torque testing device, the steps of which include:

[0077] S1: Install the engine with the crankshaft installed on the tray adapter, adjust the position of the engine tray adapter so that the axis of the engine crankshaft is in line with the axis of the torque detection device 2;

[0078] S2: The horizontal moving device 3 drives the torque detection device 2 to gradually approach the crankshaft end of the engine along the docking direction until the positioning pin 266 arranged on the drive head 263 touches the end surface of the crankshaft end, and the preliminary docking is completed;

[0079] S3: start the driving motor 21 of the torque detection device 2, the driving motor 21 drives the driving head 263 to rotate, while the horizontal moving device 3 is still gradually advancing, the crankshaft docking mechanism 26 is gradually connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com