Micro-cover pavement mixture and preparation method thereof

A mixture and stone technology, which is applied in the field of micro-covered pavement mixture and its preparation, can solve problems such as pavement structure damage, achieve the effects of reducing energy loss, ensuring strength and stability, enhancing stability and anti-deformation and distortion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

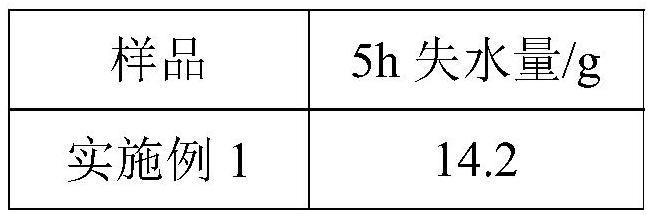

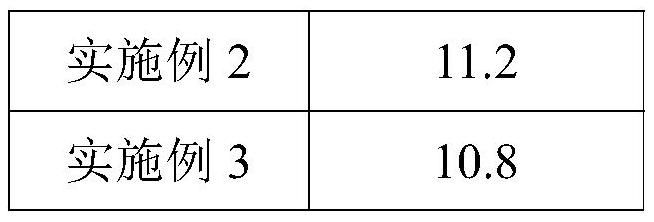

Embodiment 1

[0042] This embodiment adopts OGFC-5 gradation to prepare micro-cover pavement mixture, comprising the following steps:

[0043] ①Weigh the corresponding quality of stone (supplier, Shanghai Road and Bridge Group) according to the ratio, then pour it into the mixer, and wait for mixing.

[0044] 2. then take by weighing 40g of water, then add 5g of silane coupling agent (supplier, Guangdong Lvwei New Material Technology Co., Ltd.), 10g of zinc acetate (supplier, Tianjin Fuchen Chemical Reagent Co., Ltd.) to the water, Pour into the blender after mixing, then start the machine and stir evenly;

[0045] ③ Weigh 400g of water-based asphalt and 100g of vinyl chloride-acrylate copolymer emulsion, stir them evenly and add them to the stone material, start the mixer, and stir for 90s. , after mixing evenly, the required mixture is obtained.

Embodiment 2

[0047] The present embodiment adopts AC-10 gradation to prepare micro-cover pavement mixture, comprising the following steps:

[0048] ①Weigh the corresponding quality of stone (supplier, Shanghai Road and Bridge Group) according to the ratio, then pour it into the mixer, and wait for mixing.

[0049] ② Then weigh 45g of water, then add 10g of silane coupling agent and 12g of zinc acetate into the water, mix and pour into the mixer, then start the machine and stir evenly;

[0050] ③ Weigh 450g of water-based asphalt and 120g of vinyl chloride-acrylate copolymer emulsion, stir them evenly, add them to the stone, start the mixer, and stir for 90s. , after mixing evenly, the required mixture is obtained.

Embodiment 3

[0052] The present embodiment adopts AC-13 gradation to prepare micro-cover pavement mixture, comprising the following steps:

[0053] ①Weigh the corresponding quality of stone (supplier, Shanghai Road and Bridge Group) according to the ratio, then pour it into the mixer, and wait for mixing.

[0054] ② Then weigh 60g of water, then add 13g of silane coupling agent and 15g of zinc acetate into the water, mix and pour into the mixer, then start the machine and stir evenly;

[0055] ③ Weigh 500g of water-based asphalt and 140g of vinyl chloride-acrylate copolymer emulsion, stir them evenly and add them to the stone material, start the mixer and stir for 90s. , after mixing evenly, the required mixture is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com