Photovoltaic module packaging adhesive film and photovoltaic module

A photovoltaic module packaging and packaging film technology, which is applied in photovoltaic power generation, adhesives, electrical components, etc., can solve the problems of low yield rate of high-efficiency thinning components, white film wrinkles, and easy cracks, etc., and achieve good power gain Effect, easy preparation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Another aspect of the present invention provides a method for preparing a photovoltaic module encapsulation adhesive film, comprising the following steps:

[0077] The interlayer is prepared by a melt extrusion process;

[0078] Prepare the upper coating on one side of the interlayer at 60-200°C by one of the methods of screen coating, mask coating, spray coating, inkjet printing, screen printing or transfer printing, and / or on the interlayer The other side of the undercoating layer is prepared by one of anilox coating, mask coating, spray coating, inkjet printing, screen printing or transfer printing process at 60-200°C;

[0079] Prepare the transparent layer by laminating or coating process;

[0080] The bonding layer is prepared by lamination or coating process.

[0081] The preparation method adopted in the photovoltaic module encapsulating adhesive film in the present invention only needs to be able to prepare the encapsulating adhesive film having a five-layer s...

Embodiment 1

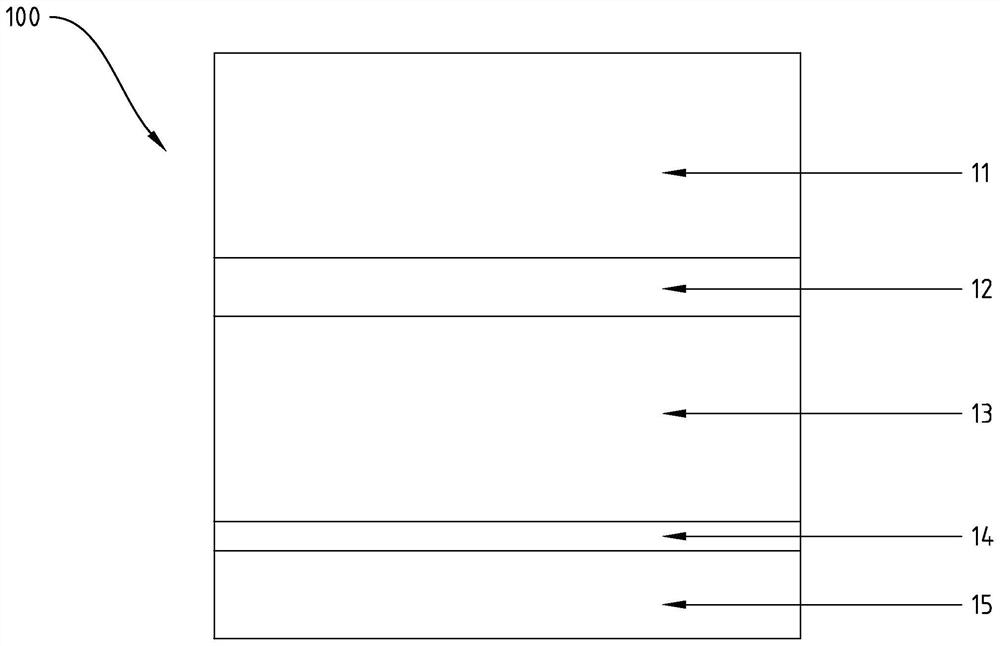

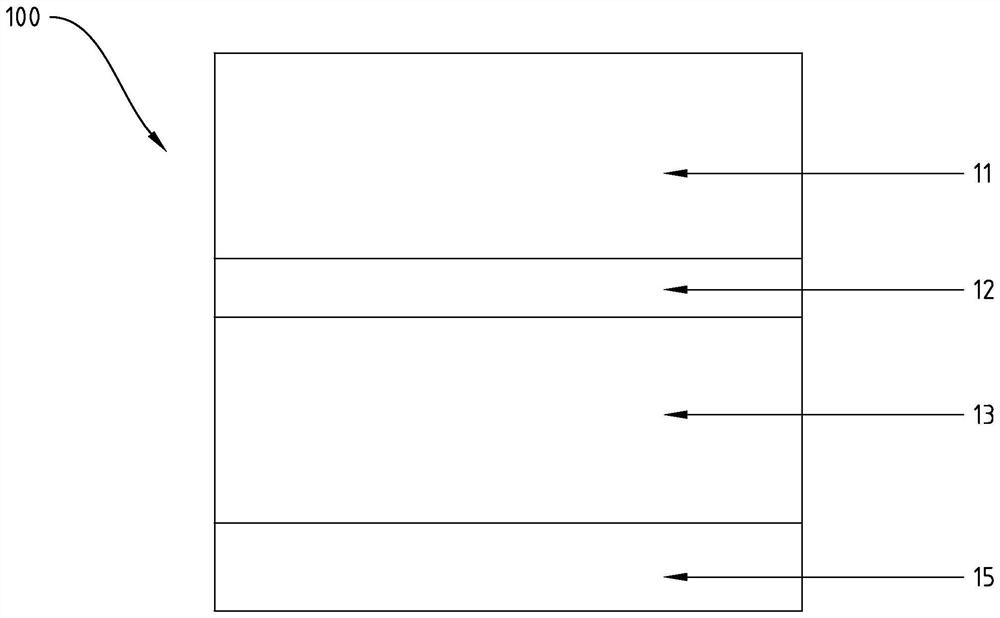

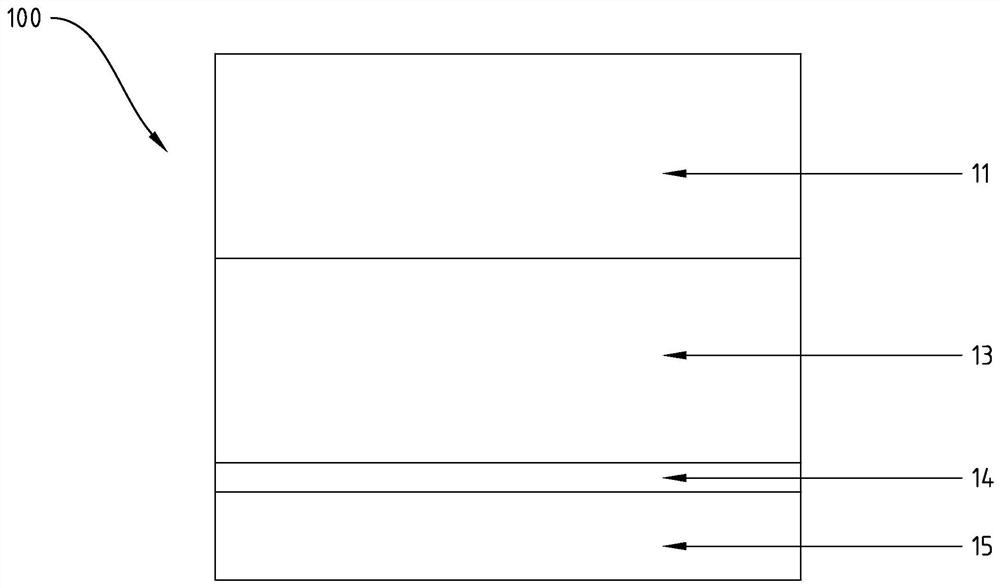

[0085] Such as figure 1 As shown, a photovoltaic module encapsulation adhesive film 100 is sequentially composed of a transparent layer 11, an upper coating 12, an interlayer 13, an undercoat 14 and an adhesive layer 15. The thickness of the transparent layer 11 is 200 μm, and the upper coating 12 The thickness of the interlayer 13 is 10 μm, the thickness of the interlayer 13 is 300 μm, the thickness of the undercoat layer 14 is 1 μm, and the thickness of the adhesive layer 15 is 100 μm.

[0086] Wherein, the transparent layer 11 is made of the following components: ethylene-vinyl acetate copolymer (DuPont) 85wt%, 2-[4-[2-hydroxyl-3-tridecyloxypropyl]oxy]-2- Hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine (BASF) 5wt%, polysuccinic acid (4-hydroxy-2,2,6 , 6-tetramethyl-1-piperidine ethanol) ester (BASF) 5wt%, 2,6-di-tert-butyl-4-methylphenol (Sanhe Chemical Industry) 2wt%, benzoyl peroxide (Graceia chemical) 3wt%;

[0087] The upper coating 12 is made from the foll...

Embodiment 2

[0092] Such as figure 1 As shown, a photovoltaic module encapsulation adhesive film 100 is sequentially composed of a transparent layer 11, an upper coating 12, an interlayer 13, an undercoat 14 and an adhesive layer 15. The thickness of the transparent layer 11 is 350 μm, and the upper coating 12 The thickness of the interlayer 13 is 50 μm, the thickness of the interlayer 13 is 200 μm, the thickness of the undercoat layer 14 is 5 μm, and the thickness of the adhesive layer 15 is 10 μm.

[0093] Wherein, the transparent layer 11 is made of the following components: ethylene-vinyl acetate copolymer (DuPont) 95wt%, 2-[4-[2-hydroxyl-3-tridecyloxypropyl]oxy]-2- Hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine (BASF) 3wt%, tris(2,4-di-tert-butylphenylphosphite) ) ester (Yongguang Chemical) 1.8wt%, tert-butylperoxycarbonate-2-ethylhexyl (Sanhe Chemical Industry) 0.1wt%, tert-butylperoxycarbonate-2-ethylhexyl (Graceia Chemicals) 0.1wt%;

[0094] The upper coating 12 is ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com