A kind of cemented carbide with high hardness and high toughness and preparation method thereof

A cemented carbide and high-toughness technology, which is applied in the field of high-hardness and high-toughness cemented carbide and its preparation, can solve the problems of insufficient temperature control and insufficient performance of cemented carbide, so as to avoid excessive grain growth, Excellent performance, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of described cemented carbide is as follows:

[0033] (1) Mixing: Mix WC powder, Co powder, Ni powder, and phosphorene, add them to absolute ethanol, ultrasonicate for 10-60 minutes, then put the mixture into a vacuum drying oven, and dry it at 60-100°C until constant weight. Obtain dry mixed powder;

[0034] (2) Sintering: put the above mixed powder into a graphite mold, place it in a spark plasma sintering equipment for sintering, vacuumize to below 20Pa, and after power on, use stepwise temperature control method to raise the temperature to 1000-1600°C, pressurize 10-40MPa, keep warm for 2-5 minutes and then cool naturally to obtain the corresponding high-hardness and high-toughness cemented carbide.

[0035] The step temperature control process is to slowly raise the temperature to 600-800°C at a rate of 20-80°C / min, and then rapidly increase the temperature to 1000-1600°C at a rate of 100-200°C / min.

[0036] Preferably, vacuumize to 1-10Pa....

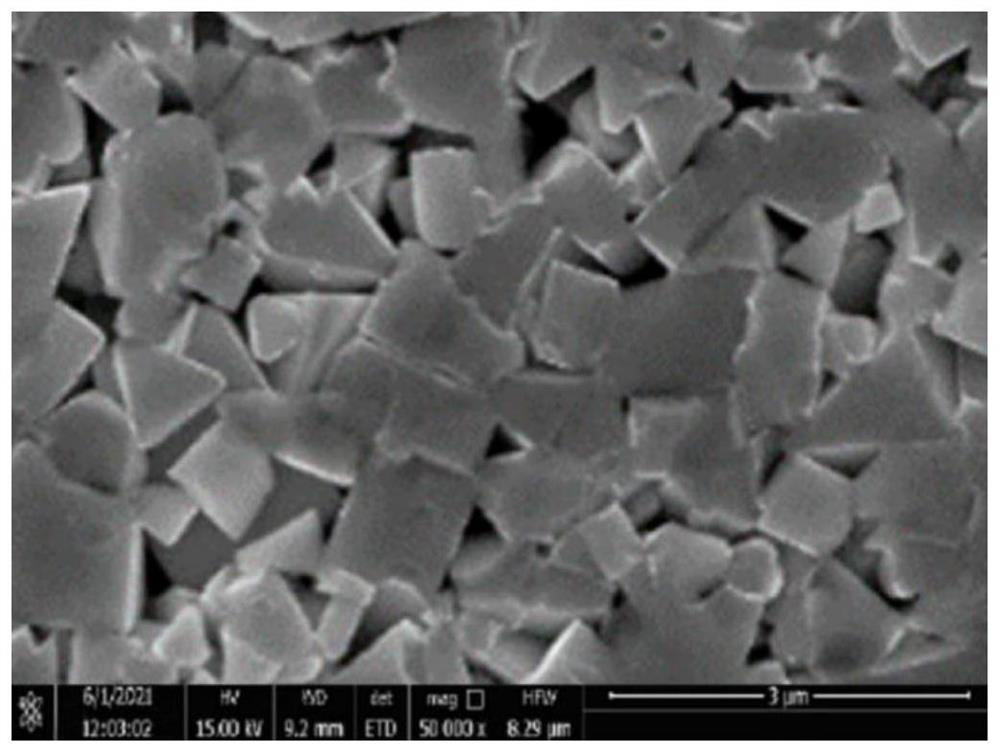

Embodiment 1

[0038] A high hardness and high toughness cemented carbide, the composition of the cemented carbide is as follows:

[0039] WC powder 87.5wt%, Co powder 8wt%, Ni powder 4wt%, phosphorene 0.5wt%.

[0040] Wherein, the WC powder includes WC powders of different particle sizes, which are respectively nano WC powder and submicron WC powder;

[0041] The particle size of the nanometer WC powder is 80nm;

[0042] The particle size of the submicron WC powder is 0.6 μm;

[0043] The mass ratio of the nanometer WC powder and the submicron WC powder is 3:1;

[0044] The preparation method of described cemented carbide is as follows:

[0045] (1) Mixing: Mix WC powder, Co powder, Ni powder, and phosphorene, add them to absolute ethanol, ultrasonicate for 30 minutes, then put the mixture in a vacuum drying oven, and dry at 90°C to constant weight to obtain a dry mixed Powder;

[0046] (2) Sintering: Put the above mixed powder into a graphite mold, put it in a spark plasma sintering e...

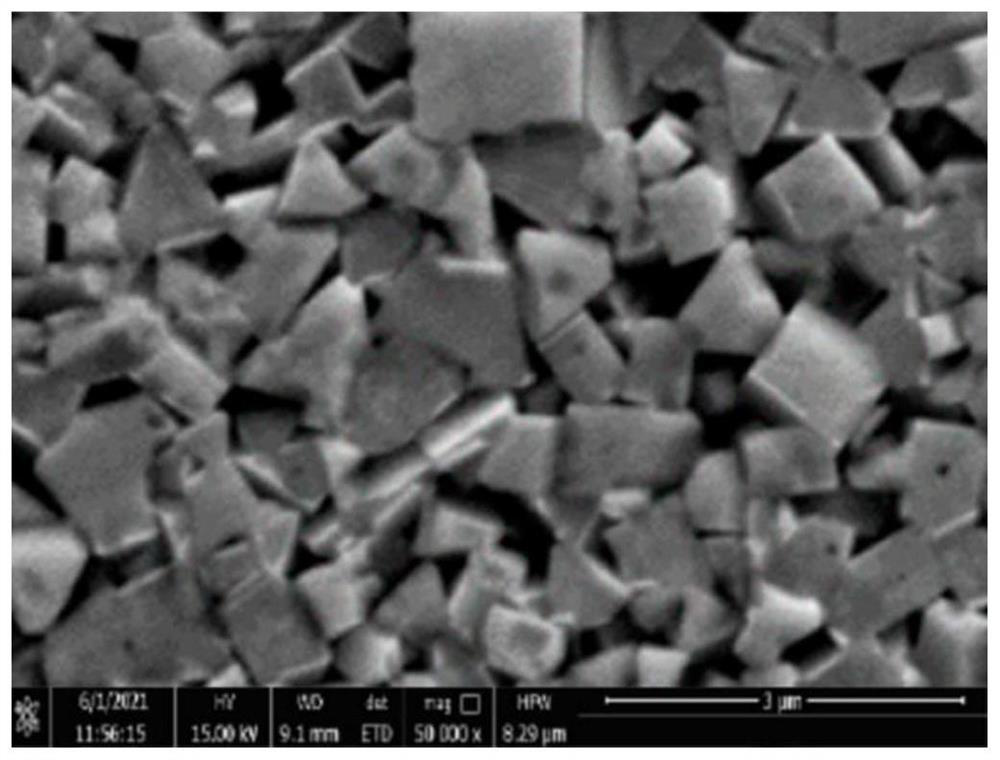

Embodiment 2

[0048] A high hardness and high toughness cemented carbide, the composition of the cemented carbide is as follows:

[0049] WC powder 89.5wt%, Co powder 5wt%, Ni powder 5wt%, phosphorene 0.5wt%.

[0050] Wherein, the WC powder includes WC powders of different particle sizes, which are respectively nano WC powder and submicron WC powder;

[0051] The particle size of the nanometer WC powder is 80nm;

[0052] The particle size of the submicron WC powder is 0.6 μm;

[0053] The mass ratio of the nanometer WC powder and the submicron WC powder is 3:1;

[0054] The preparation method of described cemented carbide is as follows:

[0055] (1) Mixing: Mix WC powder, Co powder, Ni powder, and phosphorene, add them to absolute ethanol, ultrasonicate for 30 minutes, then put the mixture in a vacuum drying oven, and dry at 90°C to constant weight to obtain a dry mixed Powder;

[0056] (2) Sintering: Put the above mixed powder into a graphite mold, put it in a spark plasma sintering e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com