Magnetorheological elastomer based on microfluidic spinning technology and preparation method thereof

A magnetorheological elastomer, spinning technology, applied in the manufacture of rayon, textiles and paper, conjugated synthetic polymer rayon, etc., can solve the complex preparation method, weak rheology, magnetorheological elastomer The problem of low magneto-induced effect, etc., to achieve the effect of simple preparation method, high magneto-induced effect, and overcoming easy sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

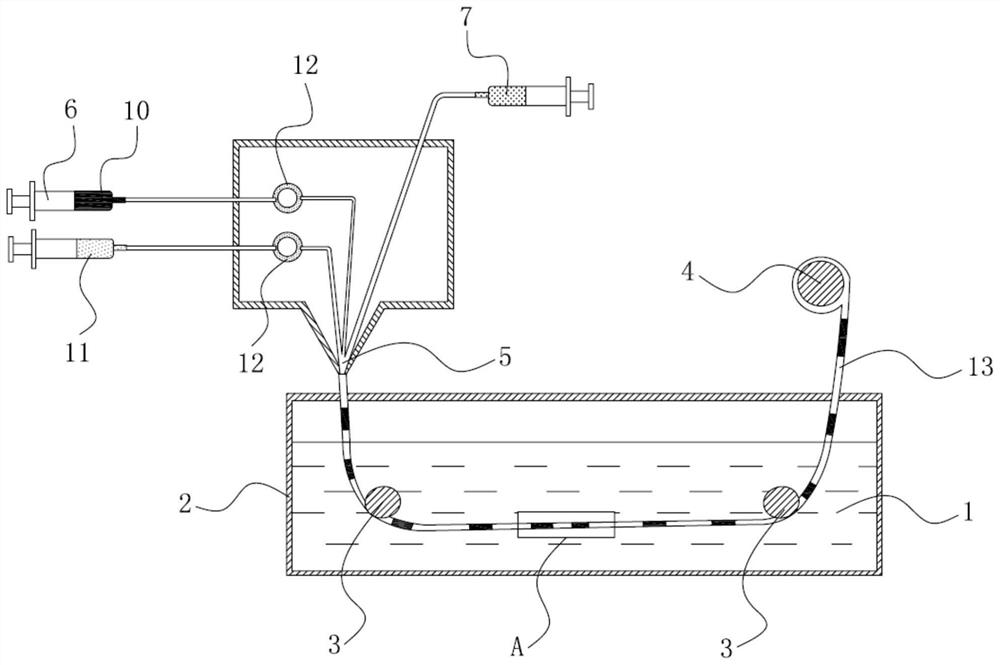

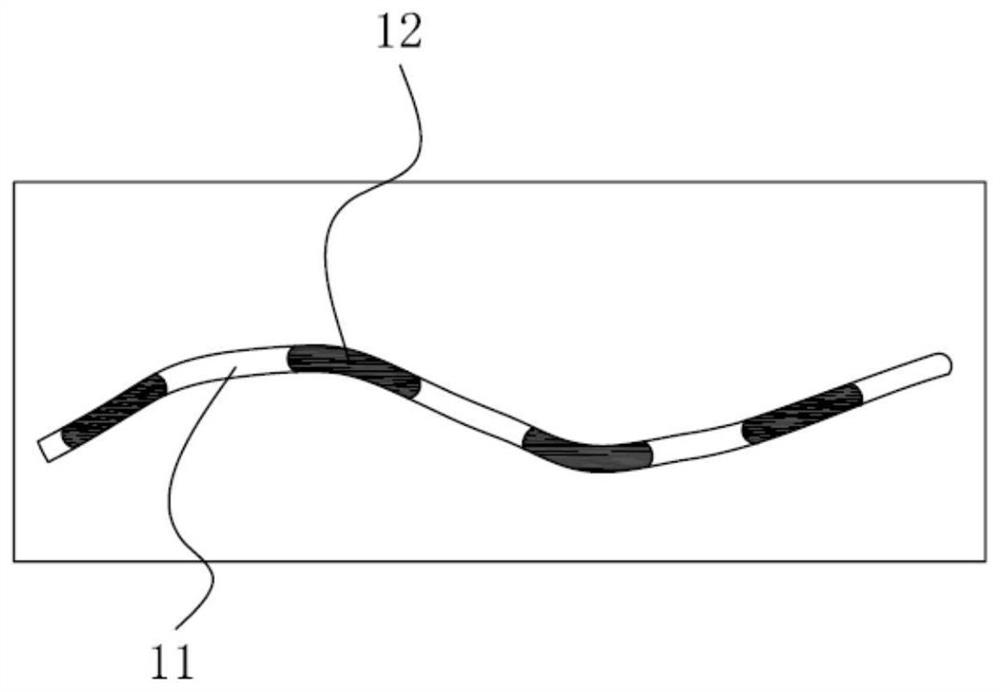

[0026] A magnetorheological elastomer based on microfluidic spinning technology, the magnetorheological elastomer is prepared by using microfluidic spinning technology, with thermoplastic elastomer solution as the skin layer, magnetorheological fluid and thermoplastic elastomer solution The magneto-rheological elastic fiber is a sheath-core structure with a core layer, wherein the magnetorheological fluid is filled into the core layer in an intermittent filling manner.

[0027] In this embodiment, the carbonyl iron iron content in the magnetorheological fluid is 30wt%, the thermoplastic elastomer is SEBS, and the mass fraction of the SEBS solution is 45%, and the interval length of the magnetorheological material in the fiber core layer can be arbitrary according to actual needs. adjust. Specifically, the filling volume of the magnetorheological fluid can be adjusted through the programmable filling method, so that the elastic body can exhibit different mechanical properties a...

Embodiment 2

[0036] A magnetorheological elastomer based on microfluidic spinning technology, the magnetorheological elastomer is prepared by using microfluidic spinning technology, with thermoplastic elastomer solution as the skin layer, magnetorheological fluid and thermoplastic elastomer solution The magneto-rheological elastic fiber is a sheath-core structure with a core layer, wherein the magnetorheological fluid is filled into the core layer in an intermittent filling manner.

[0037] In this embodiment, the iron content in the magnetorheological fluid is 70wt%, the thermoplastic elastomer is SEBS, and the mass fraction of the SEBS solution is 20%, and the interval length of the magnetorheological material in the fiber core layer can be adjusted arbitrarily according to actual needs. Specifically, the filling volume of the magnetorheological fluid can be adjusted through the programmable filling method, so that the elastic body can exhibit different mechanical properties at different ...

Embodiment 3

[0044] A magnetorheological elastomer based on microfluidic spinning technology. The magnetorheological elastomer is prepared by using microfluidic spinning technology. The thermoplastic elastomer solution is used as the skin layer, and the magnetorheological fluid and thermoplastic elastomer solution are A magnetorheological elastic fiber with a sheath-core structure of the core layer, wherein the magnetorheological fluid is filled into the core layer in an intermittent filling manner.

[0045] In this embodiment, the iron content in the magnetorheological fluid is 70wt%, the thermoplastic elastomer is SEBS, and the interval length of the magnetorheological materials in the fiber core layer can be adjusted arbitrarily according to actual needs. Specifically, the filling volume of the magnetorheological fluid can be adjusted through the programmable filling method, so that the elastic body can exhibit different mechanical properties at different positions.

[0046] A method fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com