An ionic antibacterial and anti-mite heat storage fabric and its processing technology

A processing technology and fabric technology, applied in the field of ionic antibacterial anti-mite heat storage fabric and its processing technology, can solve the problems of connection and fusion, low drying efficiency, affecting fabric efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

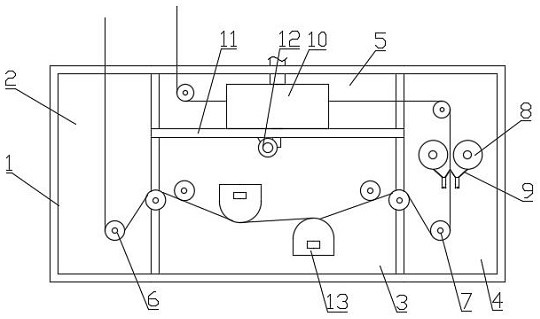

[0033] see Figure 1-7 As shown, the present invention is an ionic antibacterial and anti-mite heat storage fabric, including a box body 1, a dust removal chamber 2, an ionization chamber 3, a coating chamber 4, and a drying chamber 5;

[0034] The box body 1 is provided with a dust removal chamber 2, an ionization chamber 3, a coating chamber 4 and a drying chamber 5, wherein the dust removal chamber 2 and the drying chamber 5 are located on both sides of the box body 1, and the ionization chamber 3 and the coating chamber 4 Located in the middle of the box body 1, the coating chamber 4 is located above the ionization chamber 3, and the fabrics pass through the dust removal chamber 2, ionization chamber 3, coating chamber 4 and drying chamber 5 in sequence, and respectively correspond to the dust removal work on the fabrics, ionization Compounding the ions on the fabric, coating the anti-mite finishing agent and heat storage finishing agent on the fabric by dipping, and final...

Embodiment 2

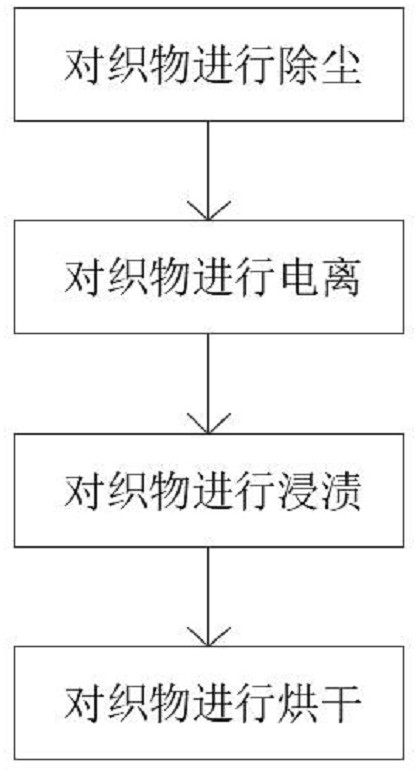

[0048] A processing technology for an ion antibacterial and anti-mite heat storage fabric, comprising the following steps:

[0049] Step 1: Add the mixed solution of anti-mite finishing agent and heat storage finishing agent into the coating chamber 4,

[0050] Then the fabric is passed into the dedusting chamber 2, the ionization chamber 3, the coating chamber 4 and the drying chamber 5 in sequence;

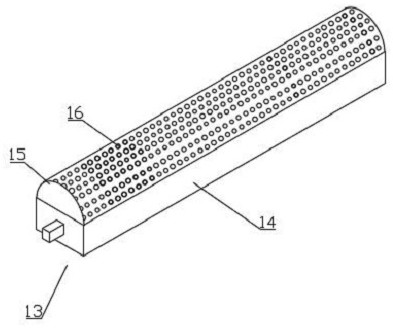

[0051] Step 2: The fabric first passes through the dust removal chamber 2, and is dedusted by the electrostatic precipitator in the dust removal chamber 2. Then, after passing through the ionization chamber 3, the ion generator 14 works to generate ions, and then the ions are compounded on the fabric. An arc-shaped casing 15 is arranged on the output end of the generator 14, so that the fabric can be in contact with the arc-shaped casing 15 during the transmission process, and will be compounded on the fabric. The ion generating device 13 ensures that the fabric is ionized. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com