Ion exchange resin-disperse dye one-bath dyeing method

A technology of ion exchange resin and disperse dyes, which is applied in the field of textile printing and dyeing, can solve the problems that ordinary disperse dyes cannot be applied, achieve the effects of reducing the use and difficulty of wastewater treatment, wide application range, and improving energy consumption and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

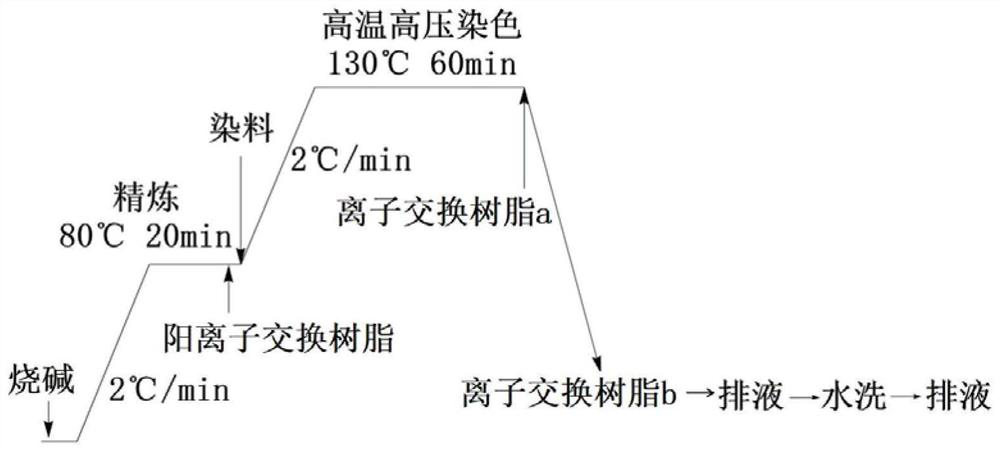

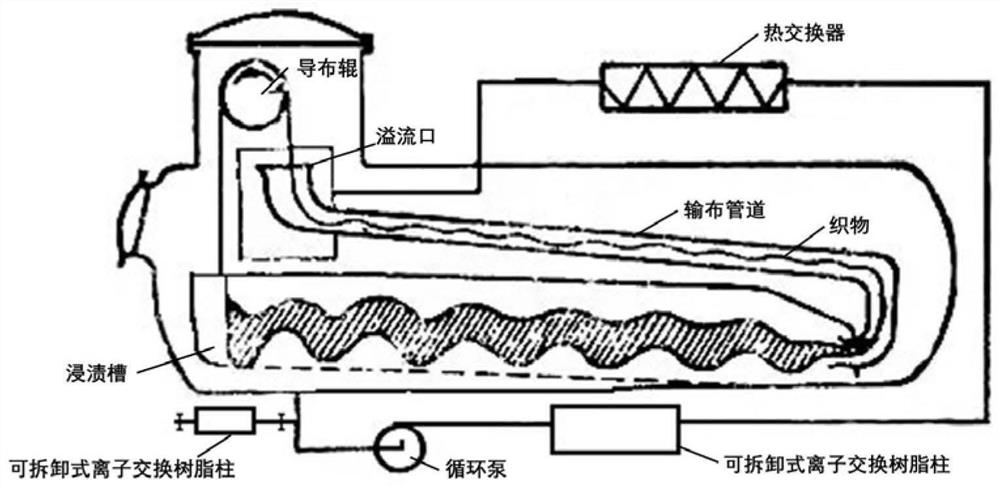

[0043] Pre-treatment dyeing one-bath process as attached figure 1 As shown, select pure polyester plain weave gray fabric with a weight of 200KG. In the high-temperature and high-pressure overflow dyeing machine, the total liquid volume is 2000 liters, 3KG sodium hydroxide is added as a refining agent, and the polyester gray cloth is put into the dyeing machine for refining. After the end, the waste liquid is filled with 150KG pretreated cationic resin Column 90s, at this time the pH value of the dye bath is 6.21, add 0.4KG C.I. Disperse Orange 30, the structural formula of the dye is as follows:

[0044]

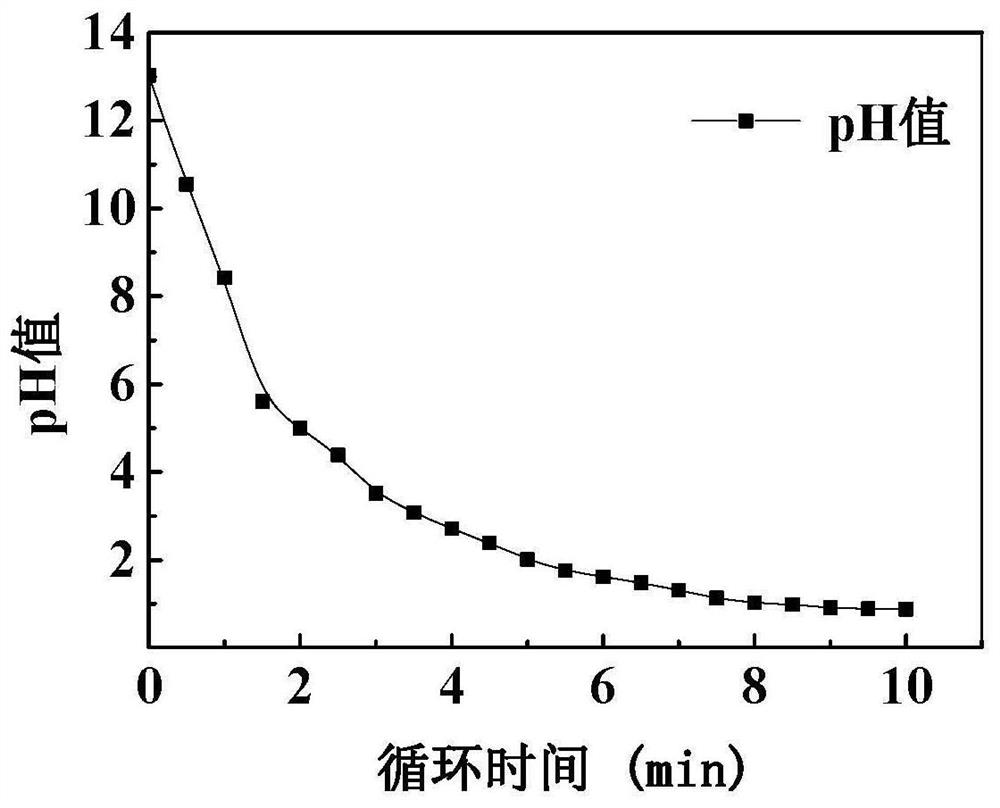

[0045] The refining bath was heated to 80°C at a heating rate of 2°C / min, and kept for 15 minutes. After the waste liquid passed through the cationic resin column for 90 seconds, the dye was added, and the temperature was raised to 130°C at a heating rate of 2°C / min, and kept for 60 minutes. The waste liquid flows through the cation resin column, naturally cools down to...

Embodiment 2

[0047] Pre-treatment dyeing one-bath process as attached figure 1 As shown, select pure polyester double-sided twill gray fabric with a weight of 200KG. In the high-temperature and high-pressure overflow dyeing machine, add 4KG sodium hydroxide as a refining component, the total liquid volume is 2000 liters, put the polyester gray cloth into the dyeing machine for refining, and after the end, the waste liquid is filled with 150KG pretreated cations Resin column 90s, at this time the pH value of the dye bath is 6.85, add 0.4KG C.I. disperse blue 359, the structural formula of the dye is as follows:

[0048]

[0049] The refining bath was heated to 80°C at a heating rate of 2°C / min, and kept for 15 minutes. After the waste liquid passed through the cationic resin column for 90 seconds, the dye was added, and the temperature was raised to 130°C at a heating rate of 2°C / min, and kept for 60 minutes. The waste liquid flows through the cation resin column, naturally cools down to ...

Embodiment 3

[0051] Pre-treatment dyeing one-bath process as attached figure 1 As shown, select pure polyester double-sided twill gray fabric with a weight of 200KG. In the high-temperature and high-pressure overflow dyeing machine, add 3KG sodium hydroxide and 3KG refining agent HE0815 as refining components, the total liquid volume is 2000 liters, put the polyester gray cloth into the dyeing machine for refining, and then pass the waste liquid through the filling 150KG pretreated cationic resin column for 90s, at this time the pH value of the dyeing bath is 7.05, add 0.4KG C.I. Disperse Red 3B, the structural formula of the dye is as follows:

[0052]

[0053] The refining bath was heated to 80°C at a heating rate of 2°C / min, and kept for 15 minutes. After the waste liquid passed through the cationic resin column for 90 seconds, the dye was added, and the temperature was raised to 130°C at a heating rate of 2°C / min, and kept for 60 minutes. The waste liquid flows through the cation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com