Vernier caliper for measuring shaft shoulder distance and measuring method

A vernier caliper and shaft measuring technology, which is applied in the field of measurement, can solve the problem that the distance from the shaft shoulder to the center of the fork ear hole cannot be measured on site, and achieve the effects of benefiting production efficiency, ensuring machining accuracy, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

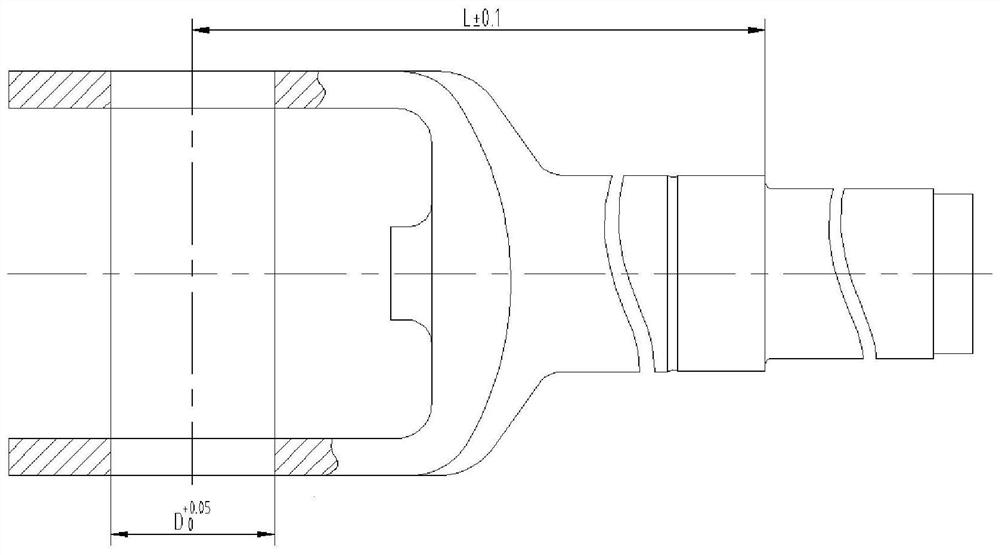

[0022] like figure 1 Shown is a schematic diagram of the shaft journal lug parts. There are two lug holes opposite to each other at the lug end, and the other end is the shaft shoulder end. The existing technology cannot measure the distance between the lug hole and the shaft shoulder. Therefore, this application proposes a A vernier caliper capable of measuring the distance from a fork lug hole to a shaft shoulder and a measuring method.

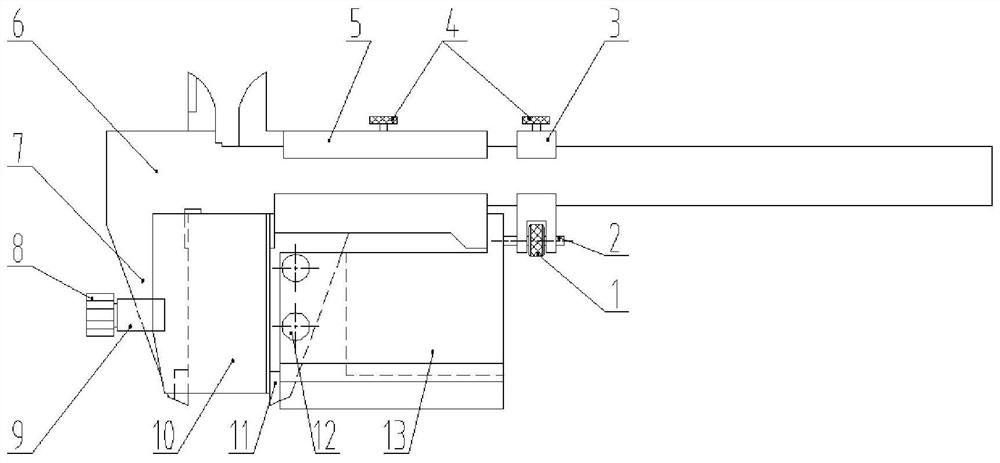

[0023] like figure 2 As shown, a vernier caliper for measuring the shaft-shoulder distance includes a fine-tuning nut 1, a screw rod 2, a micro-movement frame 3, a fastening screw 4, a vernier ruler 5, a main ruler 6, a fixed jaw 7, a locking screw 8, and a clip 9. Measuring head 10, movable claw 11, rivet 12 and positioning block 13,

[0024] The main structure of the vernier caliper includes the main ruler 6 and the vernier ruler 5. The vernier ruler 5 is movably installed on the main ruler 6, and the vernier ruler 5 is provided with a...

Embodiment 2

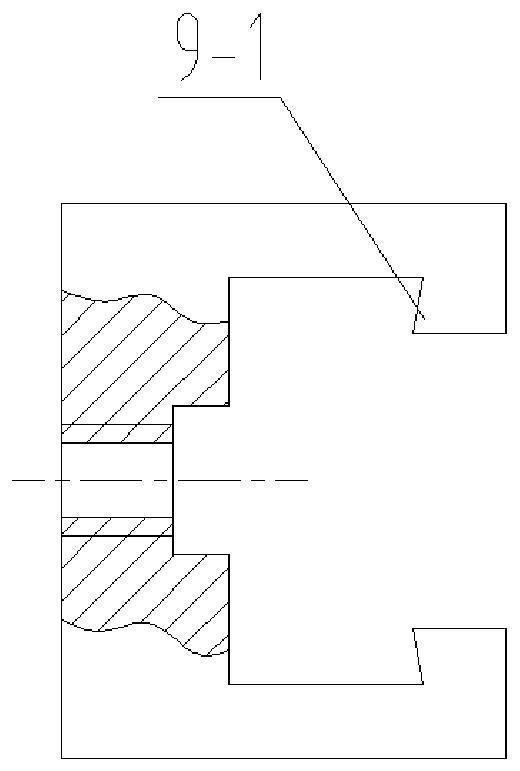

[0031] The method of measuring the vernier caliper for measuring the shaft-shoulder distance. When measuring, the arc measuring head 10-2 of the measuring head 10 fits the inner wall of the fork ear hole to complete the centering of the measuring point, and the V-shaped groove 13-1 of the positioning block 13 is placed On the outer circle adjacent to the shaft shoulder, at the same time, the measuring surface of the movable claw 11 is closely attached to the end surface of the shaft shoulder, and the nut 1 is manually fine-tuned to make the measuring surface and the end surface of the shaft shoulder completely fit, and the reading of the vernier caliper is read, and the reading is The distance between the journal yoke trunnion shoulder and the center of the yoke hole to be measured.

Embodiment 3

[0033] A vernier caliper for measuring shaft-shoulder distance, which includes a fine-tuning nut 1, a screw rod 2, a micro-movement frame 3, a fastening screw 4, a vernier ruler 5, a main ruler 6, a fixed claw 7, a locking screw 8, a clip 9, Measuring head 10, movable claw 11, rivet 12 and positioning block 13. There are scales on the main chi 6 and the vernier chi 5, and the chi body of the main chi 6 and the vernier chi 5 have measuring claws up and down; Bottom movable jaw 11 and an end of vernier ruler (5) are integrally manufactured.

[0034] The fine-tuning nut 1 is located in the groove of the fine-tuning frame 3, one end of the screw rod 2 is connected and fixed with the vernier 5 through threads, and the other end is connected with the fine-tuning nut 1 and the fine-moving frame 3 through threads, and rotating the fine-tuning nut 1 will realize Vernier scale 5 fine adjustments. The micro-movement frame 3 and the vernier frame 5 are provided with a fastening screw 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com