Method for manufacturing wire harness and wire harness

A technology for manufacturing wires and wire harnesses, applied in the field of electrical connection, can solve the problems of low automation degree of wire harness production and high production cost, and achieve the effects of fast processing speed, high manufacturing efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

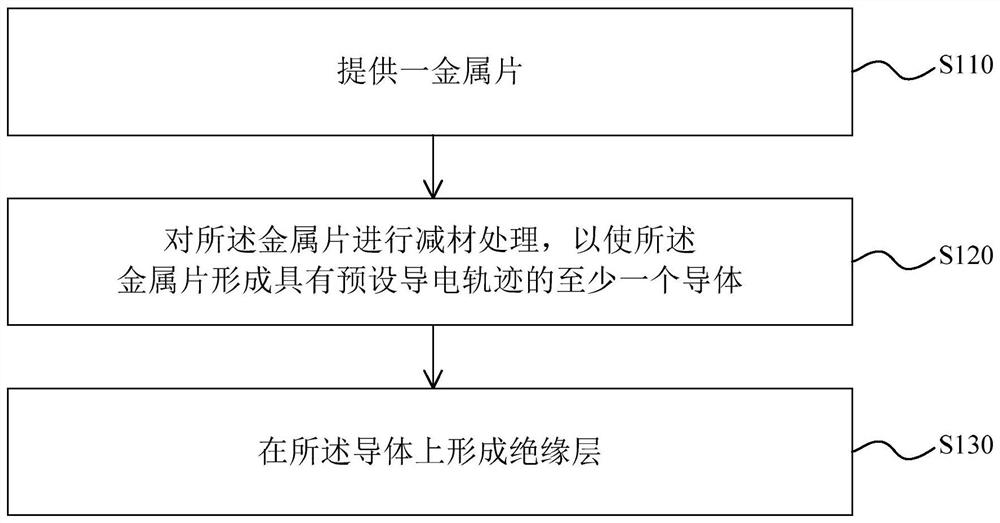

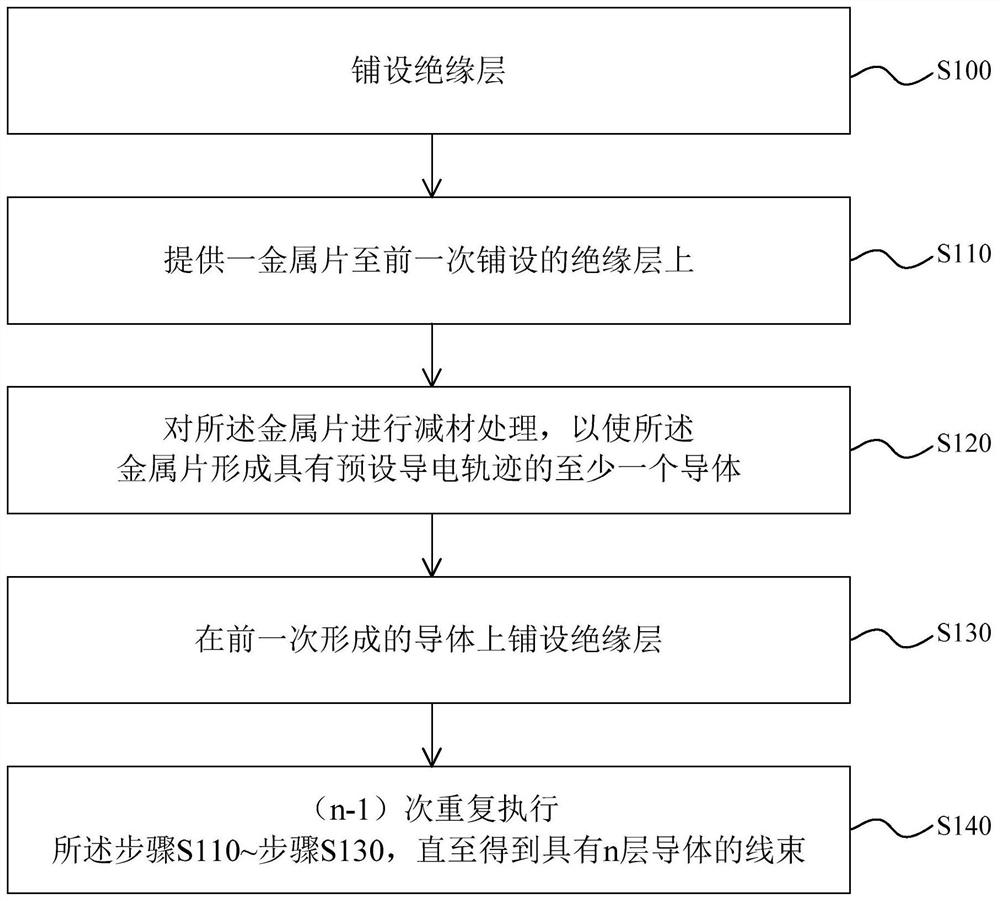

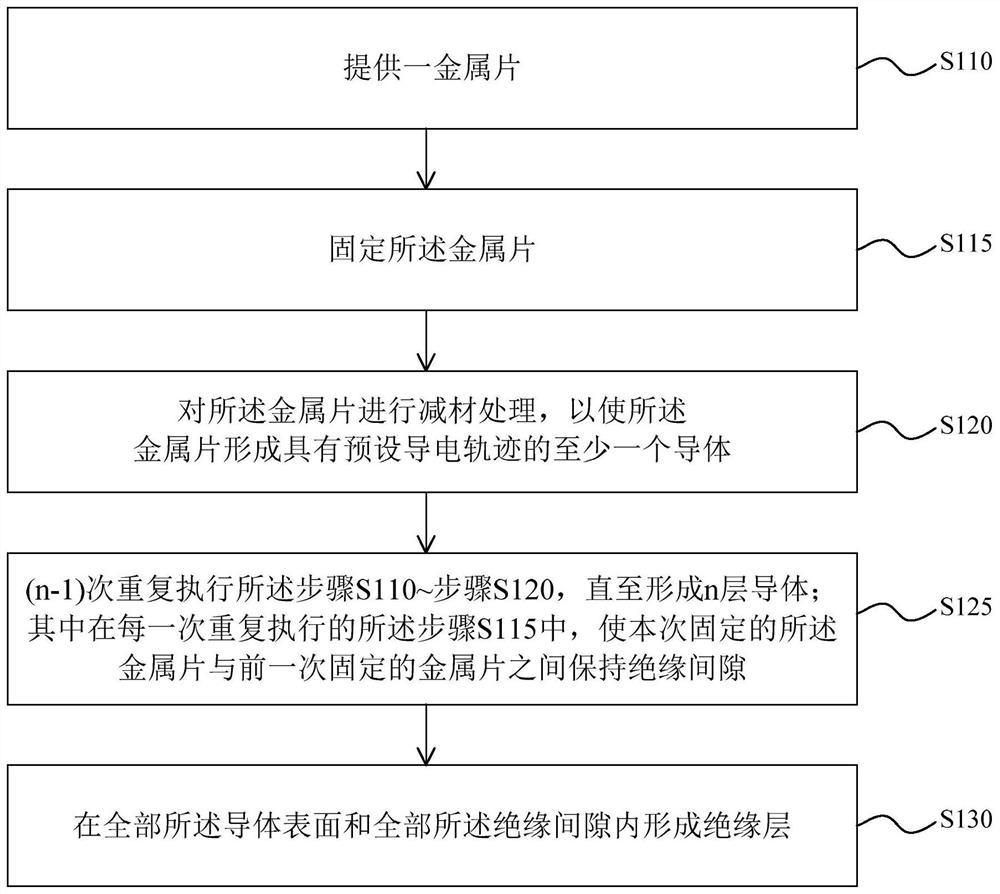

[0056] The present invention provides a method of manufacturing a wire harness, such as figure 1 , Figure 4 , Figure 5 shown, including the following steps:

[0057] Step S110: providing a metal sheet 1;

[0058] Step S120: performing material reduction on the metal sheet 1, so that the metal sheet 1 forms at least one conductor 2 with a preset conductive track, wherein the preset conductive track can be a conductive track with any direction, and can be set according to actual needs;

[0059] Step S130 : forming an insulating layer 3 on the conductor 2 to wrap the conductor 2 through the insulating layer 3 .

[0060] The invention provides a method for manufacturing wire harnesses in a subtractive manner. The unnecessary part on the metal sheet is removed, and the remaining part is the required conductor, and then an insulating protective layer is formed on the outside of the conductor to obtain the wire harness. The manufacturing method is simple. It is convenient to ma...

Embodiment approach 2

[0105] Such as Figure 5 to Figure 7 As shown, the present invention also provides a wire harness manufactured by the method for manufacturing a wire harness in the first embodiment. The beneficial effects of this implementation mode are the same as those of the first implementation mode, and will not be repeated here.

[0106] In one embodiment, the metal sheet 1 is a rigid metal sheet. The rigid metal sheet has good rigidity and is easy to fix. The metal sheet can be shaped by forging, rolling, bending, stamping, extrusion or integral casting, and then the shaped metal sheet can be fixed.

[0107] In one embodiment, the metal sheet 1 is a flexible metal sheet. The flexible metal sheet can be a thin metal plate or a metal foil, which can be easily deformed, and can be used in some wire harnesses that do not require high current but have complex shapes.

[0108] In one embodiment, the material of the metal sheet 1 includes nickel or its alloys, cadmium or its alloys, zircon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com