High-ionic-conductivity lithium battery diaphragm with self-closing function and preparation method of high-ionic-conductivity lithium battery diaphragm

A technology of ionic conductivity and lithium battery diaphragm, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of low ion conductivity, no self-shutdown function, and low thermal stability of lithium battery diaphragms, etc., to achieve High thermal sensitivity and thermal dimensional stability, high safety and performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

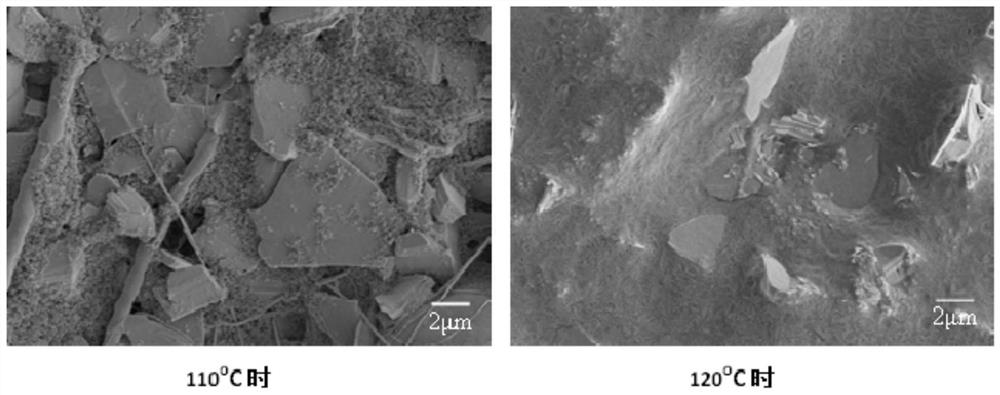

Image

Examples

Embodiment 1

[0055] A method for preparing a high ion conductivity lithium battery diaphragm with self-closing function, the specific steps are as follows:

[0056] (1) Preparation of raw materials;

[0057] Preparation of Conductive Inorganic Solutions Containing Viscous Substances:

[0058] According to the mass volume ratio of 0.5mg / mL, the conductive inorganic substance (the MXene of the lamellar structure) is dispersed in the aqueous solution, and then it is mixed with the aqueous solution containing the viscous substance (styrene-butadiene latex binder) to obtain the viscous substance. Conductive inorganic substance solution: in the prepared conductive inorganic substance solution containing viscous substances, the concentration of viscous substances is 0.001wt%.

[0059] Preparation of ceramic nanoparticle solutions containing viscous substances:

[0060] According to the mass volume ratio of 0.5mg / mL, ceramic nanoparticles (hydrophilic nano-SiO 2 particles, with an average parti...

Embodiment 2

[0082] A method for preparing a high ion conductivity lithium battery diaphragm with self-closing function, the specific steps are as follows:

[0083] (1) Preparation of raw materials;

[0084] Preparation of Conductive Inorganic Solutions Containing Viscous Substances:

[0085] According to the mass volume ratio of 0.5mg / mL, the conductive inorganic substance (the MXene of the lamellar structure) is dispersed in the aqueous solution, and then it is mixed with the aqueous solution containing the viscous substance (styrene-butadiene latex binder) to obtain the viscous substance. Conductive inorganic substance solution: in the prepared conductive inorganic substance solution containing viscous substances, the concentration of viscous substances is 0.001wt%.

[0086] Preparation of ceramic nanoparticle solutions containing viscous substances:

[0087] According to the mass volume ratio of 0.5mg / mL, ceramic nanoparticles (hydrophilic nano-SiO 2 Particles, with an average parti...

Embodiment 3

[0096] A method for preparing a high ion conductivity lithium battery diaphragm with self-closing function, the specific steps are as follows:

[0097] (1) Preparation of raw materials;

[0098] Preparation of Conductive Inorganic Solutions Containing Viscous Substances:

[0099] According to the mass volume ratio of 0.5mg / mL, the conductive inorganic substance (the MXene of the lamellar structure) is dispersed in the aqueous solution, and then it is mixed with the aqueous solution containing the viscous substance (styrene-butadiene latex binder) to obtain the viscous substance. Conductive inorganic substance solution: in the prepared conductive inorganic substance solution containing viscous substances, the concentration of viscous substances is 0.001wt%.

[0100] Preparation of ceramic nanoparticle solutions containing viscous substances:

[0101] According to the mass volume ratio of 0.5mg / mL, ceramic nanoparticles (hydrophilic nano-SiO 2 particles, with an average parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com