Multi-channel capacitance coupling type plasma jet device and working method

A plasma and capacitive coupling technology, applied in the direction of plasma, electrical components, etc., can solve the mutual interference of multiple groups of anodes and cathodes, can not solve the problem of multi-channel jet, can not achieve stable and effective plasma jet, etc., to achieve high efficiency The effect of modification and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

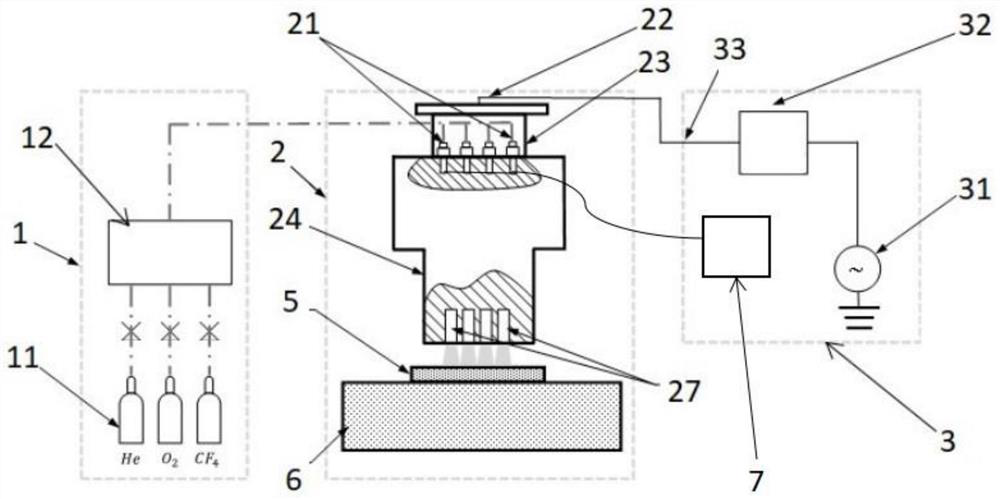

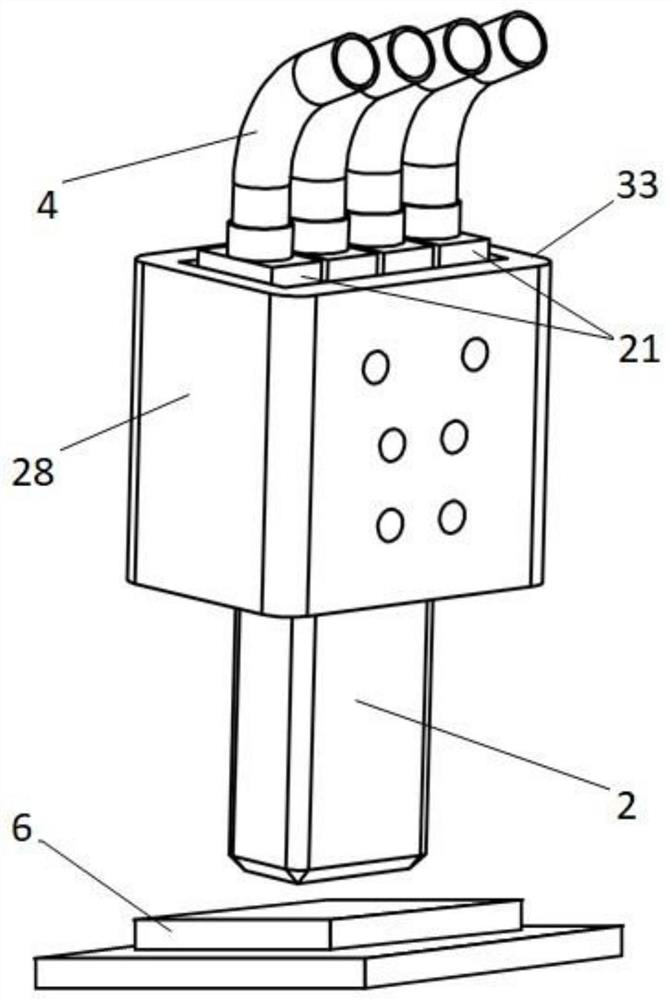

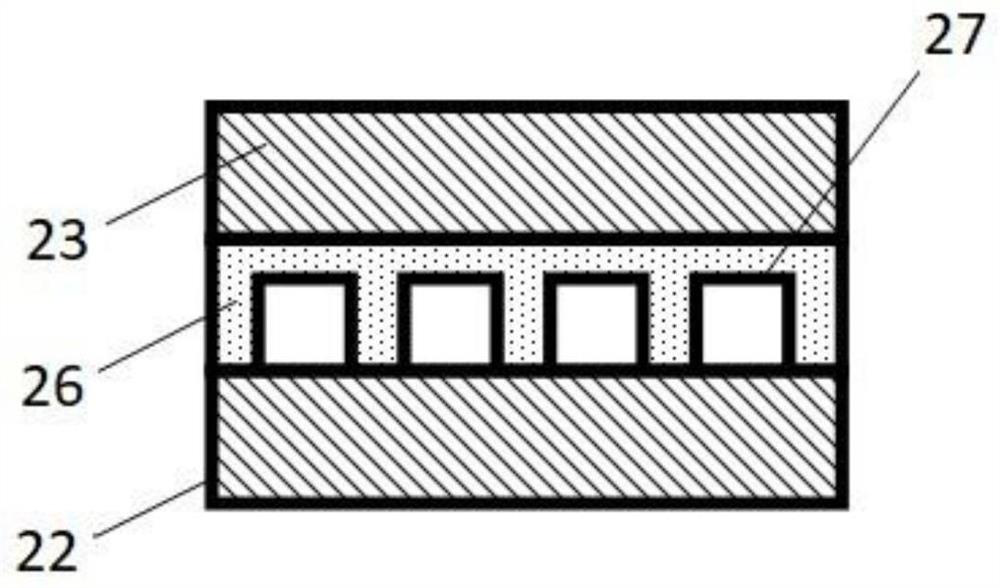

[0056] Such as figure 1 with image 3 As shown, a multi-channel capacitively coupled plasma jet device includes: a gas diversion and mixing structure 1, a plasma generator 2, a radio frequency circuit 3 and an intake pipe 4; the gas diversion and mixing structure 1 passes through the intake The pipeline 4 communicates with the plasma generator 2, the radio frequency circuit 3 is electrically connected to the plasma generator 2, and the anode plate 22, the cathode plate 23 and the insulating medium plate 26 are installed in the plasma generator 2, and the anode plate 22 and the cathode plate 23 are installed The insulating medium plate 26 is provided with a plurality of reaction channels 27 . The gas diversion and mixing structure 1 includes: a gas source 11 and a gas mixing and rectifying device 12. There are multiple gas sources 11. One end of the multiple gas sources 11 is connected to one end of the gas mixing and rectifying device 12 and passes through the gas mixing and ...

Embodiment 2

[0060] Embodiment 2 is a preferred example of Embodiment 1.

[0061] Such as figure 1 As shown, the present invention provides a multi-channel capacitively coupled plasma jet device, including functional components such as a gas diversion and mixing structure 1 , a gas flow control valve 21 , a plasma generator 2 , and a radio frequency power line interface 33 . Among them, the gas diversion and mixing structure 1 is used for the introduction, uniform mixing and air flow rectification of fluorine-containing reaction gas and inert gas; the gas flow control valve 21 is used for real-time control of gas flow into the plasma generator 2 and each of the generators. The flow rate of the reaction channel 27; the plasma generator 2 uses a high-frequency electromagnetic field to excite the inert gas into a plasma state under atmospheric pressure, so that the reactive gas is excited to generate active particles in the plasma active atmosphere; the radio frequency power line interface 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com