Heavy packaging film and preparation method thereof

A heavy-packaging and film technology, applied in the field of heavy-packaging film and its preparation, can solve the problems of poor moisture-proof and moisture-proof effect of heavy-packaging film, difficult recycling of heavy-packing film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

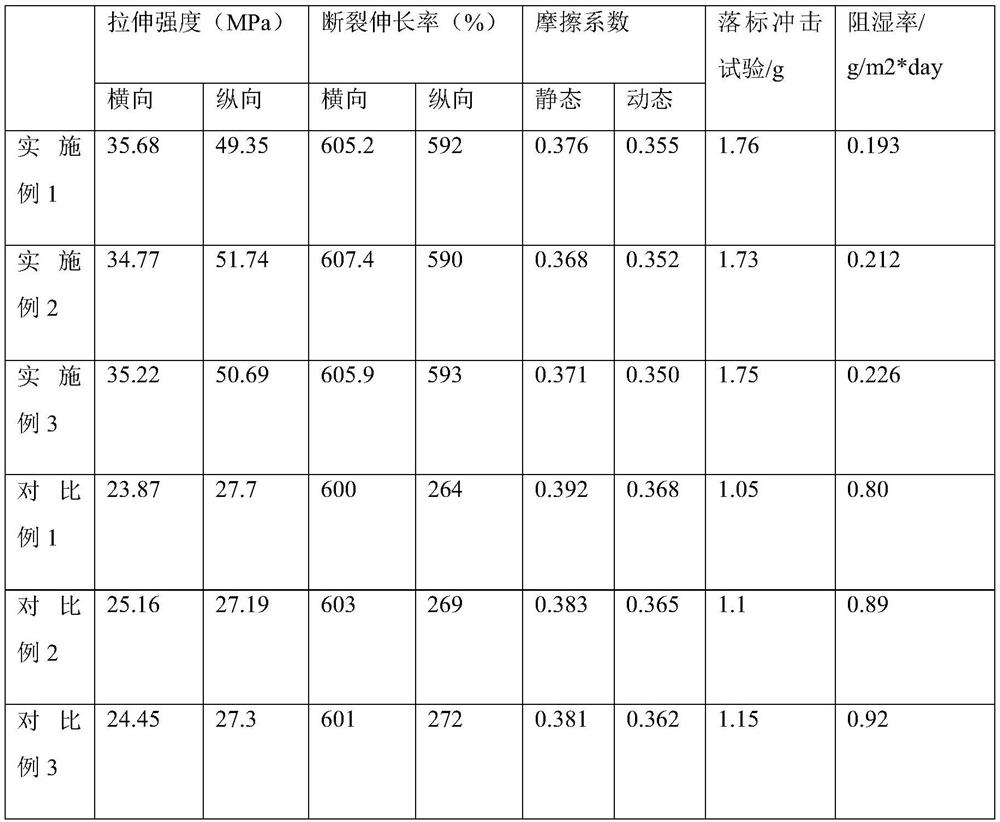

Embodiment 1

[0042] The manufacturers and models of raw materials used in this embodiment are as follows:

[0043] The first high-density polyethylene is Dow DMDH 6400;

[0044] Medium density polyethylene is Dow DOWLEX 2038.68G;

[0045] Metallocene linear low density polyethylene is Exxon 1018MA;

[0046] The second high-density polyethylene is Dow AT 6900;

[0047] The ion resin is DuPont 1650SB;

[0048] The low-density polyethylene is Shanghai Secco LL0209AA;

[0049] The first linear low density polyethylene is CNOOC Shell LDPE 2420D;

[0050] The second linear low density polyethylene is Borealis FB2310.

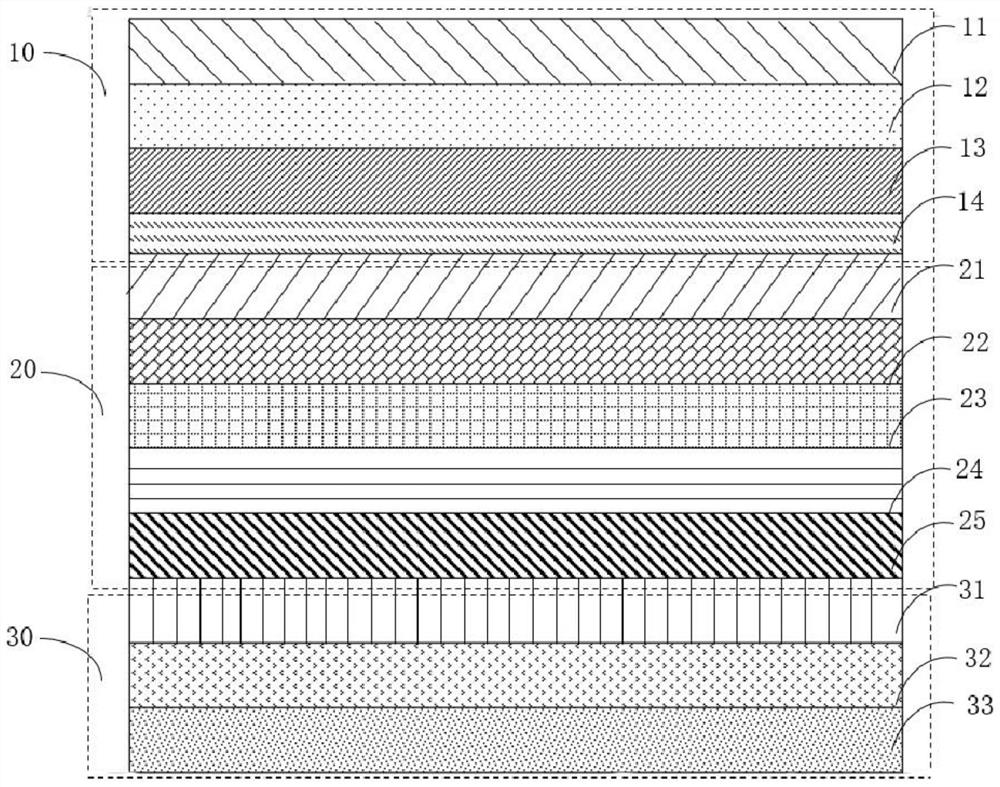

[0051] Such as figure 1 As shown, the heavy packaging film provided by the present embodiment comprises an aluminized layer, a moisture barrier layer and a heavy cladding layer closely fitted successively from the outside to the inside; the aluminized layer is three layers, and its outer layer is 1 by weight ratio: 1 The first high-density polyethylene and medium-density po...

Embodiment 2

[0058] The manufacturers and models of raw materials used in this embodiment are as follows:

[0059] The first high-density polyethylene is Dow DMDH 6400;

[0060] Medium density polyethylene is Dow DOWLEX 2038.68G;

[0061] Metallocene linear low density polyethylene is made by mixing Exxon 1018MA and Exxon 3505HH at a weight ratio of 1:1;

[0062] The second high-density polyethylene is Dow AT 6900;

[0063] The ion resin is DuPont 1650SB;

[0064] The low-density polyethylene is LDPE 2420D of China Sea Shell;

[0065] The first linear low density polyethylene is Shanghai Secco LL0209AA;

[0066] The second linear low density polyethylene is Borealis FB2310.

[0067] Such as figure 1 As shown, the heavy packaging film provided in this embodiment includes an aluminum-coated layer, a moisture barrier layer, and a heavy cladding layer that are tightly attached from the outside to the inside; the aluminum-coated layer has three layers, and the weight ratio of the outer la...

Embodiment 3

[0074] The manufacturers and models of raw materials used in this embodiment are as follows:

[0075] The first high-density polyethylene is Dow DMDH 6400;

[0076] Medium density polyethylene is Dow DOWLEX 2038.68G;

[0077] Metallocene linear low density polyethylene is Exxon 1018MA;

[0078]The second high-density polyethylene is Dow AT 6900;

[0079] The ion resin is DuPont 1650SB;

[0080] The low-density polyethylene is LDPE 2420D of China Sea Shell;

[0081] The first linear low density polyethylene is Shanghai Secco LL0209AA;

[0082] The second linear low density polyethylene is Borealis FB2310.

[0083] Such as figure 1 As shown, the heavy packaging film provided in this embodiment includes an aluminum-coated layer, a moisture barrier layer, and a heavy cladding layer that are tightly attached from the outside to the inside; the aluminum-coated layer has three layers, and the weight ratio of the outer layer is 1: 2 The first high-density polyethylene and mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com