Micro-interface hydrogenation device and method for reformate

A technology of reforming to generate oil and hydrogenation device, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of low gas-liquid mass transfer rate and hydrogenation reaction rate, low olefin hydrogenation saturation depth, The problem of unsatisfactory mixing effect, etc., can achieve the effect of increasing the phase interface area, reducing the loss of aromatics, and improving the hydrogen supply and hydrogen carrying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

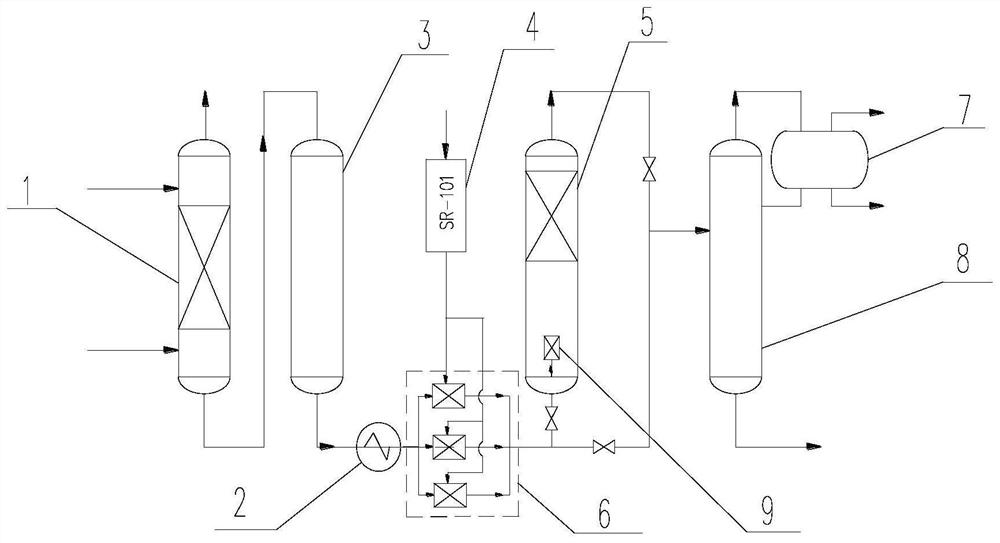

[0043] refer to figure 1 As shown, it is a reformed oil microinterface hydrogenation device according to an embodiment of the present invention, which mainly includes a hydrogenation reactor 5, and a pneumatic microinterface generator 9 is arranged in the center of the lower part of the hydrogenation reactor 5, and the hydrogenation reaction The bottom of the device 5 is provided with a material pipeline for conveying the reformed oil, and a microinterface unit 6 is arranged on the material pipeline. In this embodiment, three pneumatic microinterface generators 9 are connected in parallel to form a microinterface unit 6 . Both the pneumatic micro-interface generator 9 and the micro-interface unit 6 play the role of dispersing and crushing hydrogen, but one is inside and the other is outside, and the two cooperate with each other to achieve the best effect of crushing hydrogen.

[0044] The micro-interface unit 6 is also connected to a hydrogen filter 4 with a filtration accura...

Embodiment 2

[0056] Other operation steps are the same as in Example 1, except that the temperature at the inlet of the reactor is set at 100° C., and the pressure at the inlet of the reactor is set at 1.2 MPa.

[0057] Analytical Results: Bromine Index = 850, Aromatics Loss = 0.23%.

Embodiment 3

[0059] Other operation steps are the same as in Example 1, except that the temperature at the inlet of the reactor is set at 180° C., and the pressure at the inlet of the reactor is set at 2.0 MPa.

[0060] Analytical Results: Bromine Index = 820, Aromatics Loss = 0.27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com