High-temperature-resistant and high-toughness high-end hot work die steel and production process thereof

A technology of hot work die steel and production process, which is applied in the field of die steel, can solve the problems of material strength and thermal stability decrease, reduce die service life, and poor thermal fatigue resistance, etc., to improve ductility and toughness, and increase strength , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

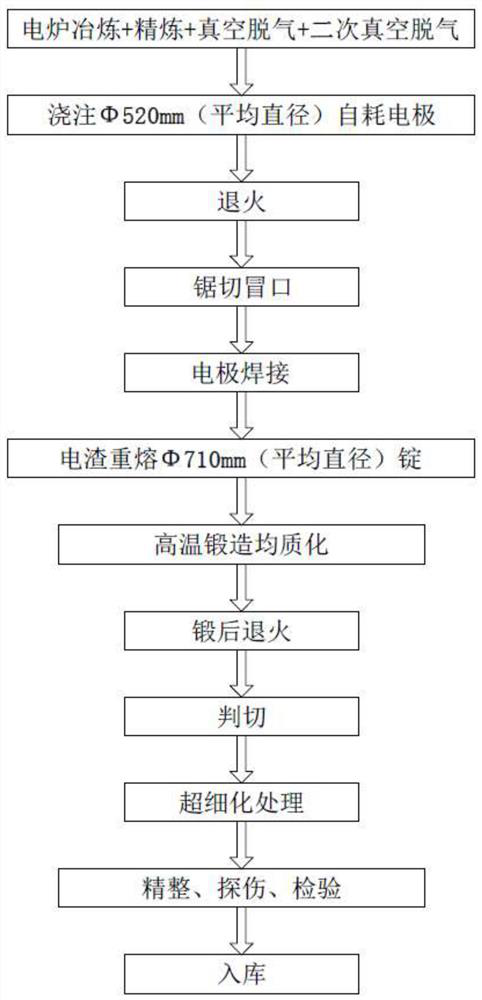

[0047] The production technique of embodiment 1, comprises the following steps:

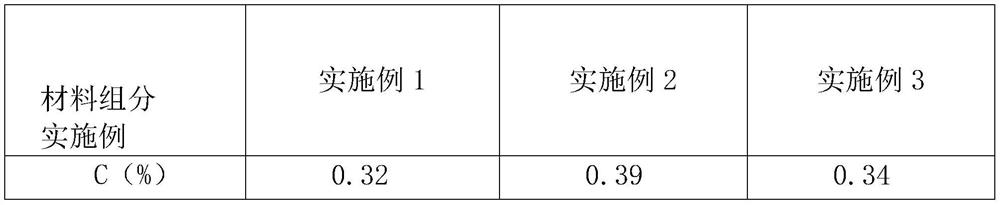

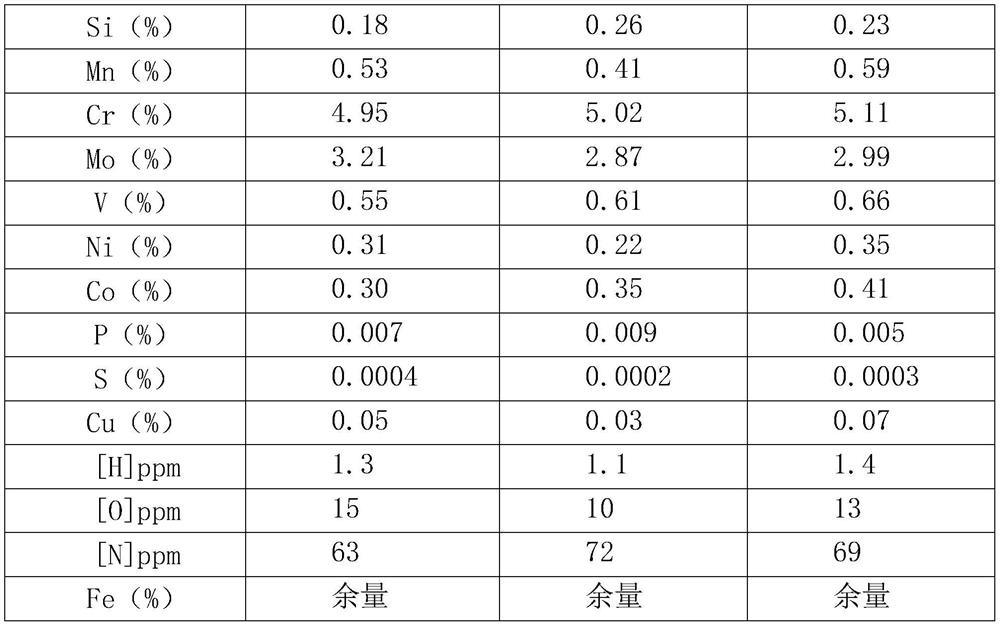

[0048] S1 Electric Furnace Smelting, Refining, Vacuum Degassing, Secondary Vacuum Degassing: Weigh the steel material composed of the material composition of Example 1 in Table 1 and put it into the electric furnace to smelt it into molten steel, then put the resulting molten steel into the refining furnace Refining, and finally vacuum degassing and secondary vacuum degassing for molten steel in VD ladle refining furnace;

[0049] In the electric furnace smelting step: S101 controls the oxygen pressure at 0.4~0.5MPa during the melting period of the steel material, keeps the temperature ≥ 1560°C, and mixes [Mo] to the lower limit;

[0050] Oxygen pressure is controlled at 0.6-0.8Mpa during the oxidation period of S102, and oxygen is blown to oxidize and decarburize and dephosphorize;

[0051] Add 100kg Si-Mn alloy or C-Mn alloy at the end of S103 oxidation period, and the net boiling time of molt...

Embodiment 2

[0075] The production process of embodiment 2 and embodiment 3 is similar to the production process of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com