Low-nitrogen combustor with airflow in air-gas channel separated by corrugated plate and uniformly mixed alternately in same direction

A low-nitrogen burner, corrugated plate technology, applied in gas fuel burners, burners, combustion methods, etc., can solve the problem of insufficient oxygen concentration, achieve novel and unique structure, environmental protection technical requirements, economic and social benefits huge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

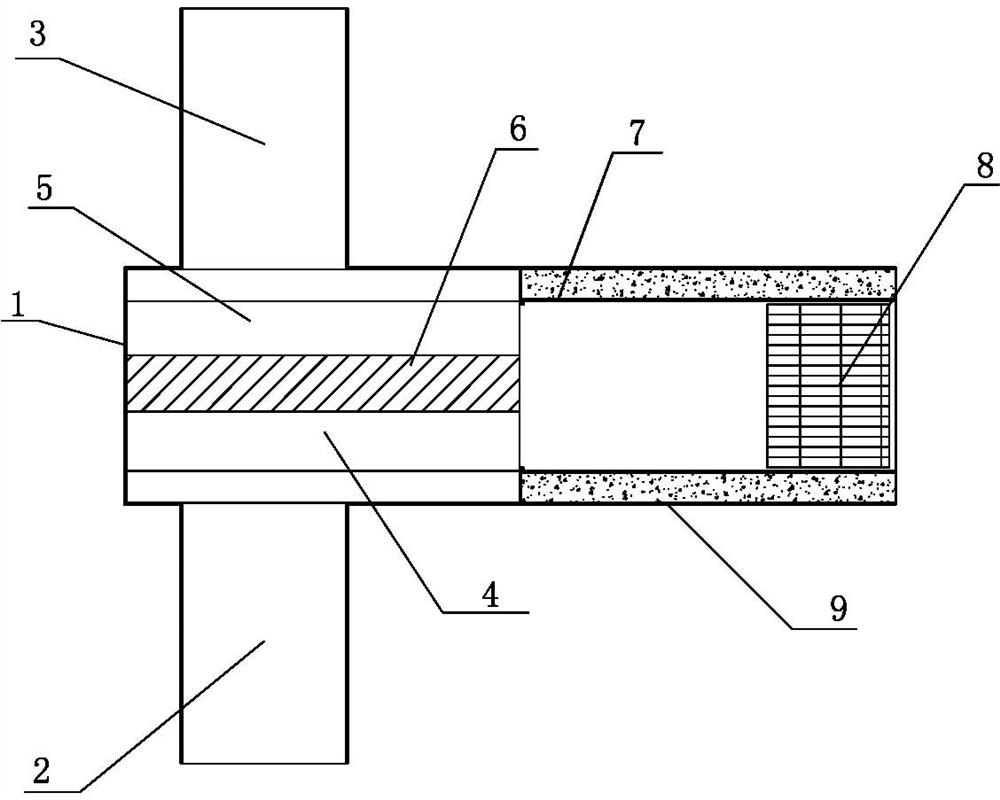

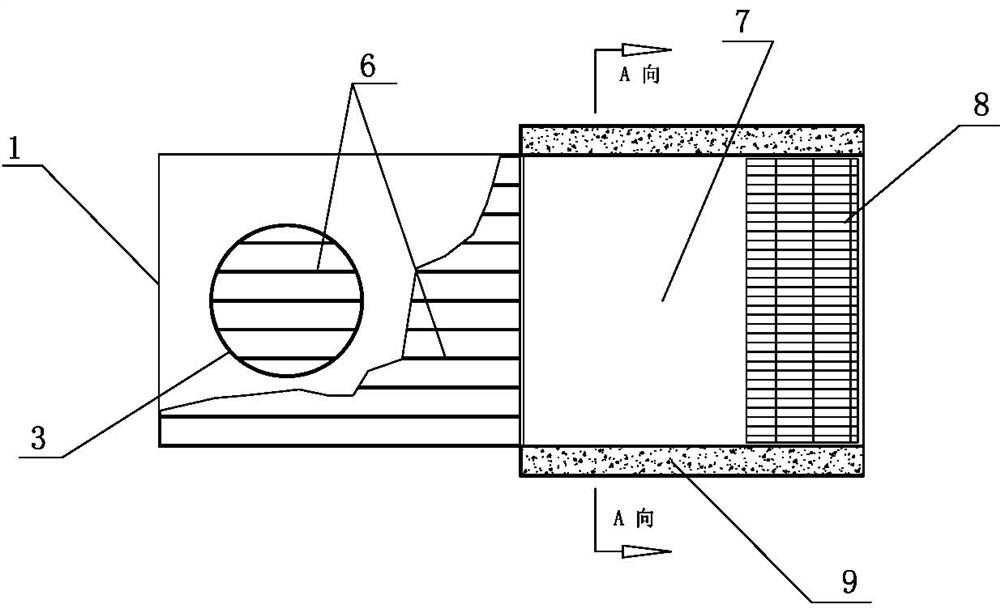

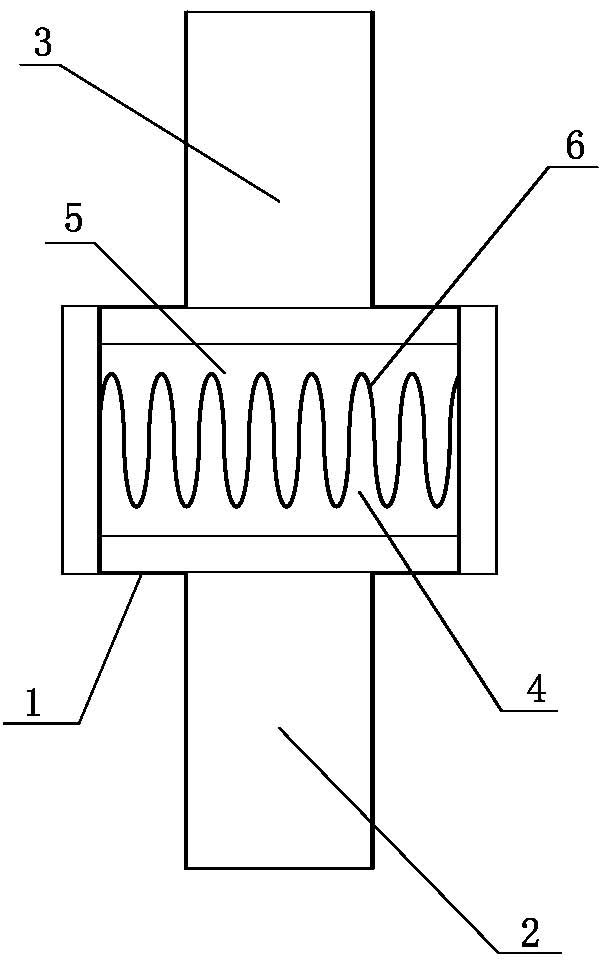

[0010] The specific structure and implementation of the burner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] Depend on Figure 1-4 As shown, the present invention is a low-nitrogen burner in which the corrugated plate separates the empty gas channel and the gas flow is uniformly mixed in the same direction, including a shell 1, a gas inlet pipe 2, an air inlet pipe 3, a corrugated partition plate 6, and a gas distribution channel 4. Air distribution channel 5, air gas premixing channel 7 and combustion-supporting ceramic porous body 8. The housing 1 is a hollow body with a rectangular cross section. Partition plate 6 divides the inner space of the shell into upper and lower parts, the upper part is the air distribution channel 5, the lower part is the gas distribution channel 4, one end of the corrugated partition plate 6 is fixedly connected with the closed end of the burner’s rectangular section shell 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com