Intelligent processing and feeding production line for total mixed ration

A production line and fully mixed technology, applied in food processing, animal feeding equipment, cleaning equipment, etc., can solve the problems of lack of scientific feeding, feeding data in cowsheds, difficult real-time monitoring of management data, high labor costs, etc., and achieve improvement Stirring and cutting effect, avoiding low efficiency of manual recovery, convenient tool change and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

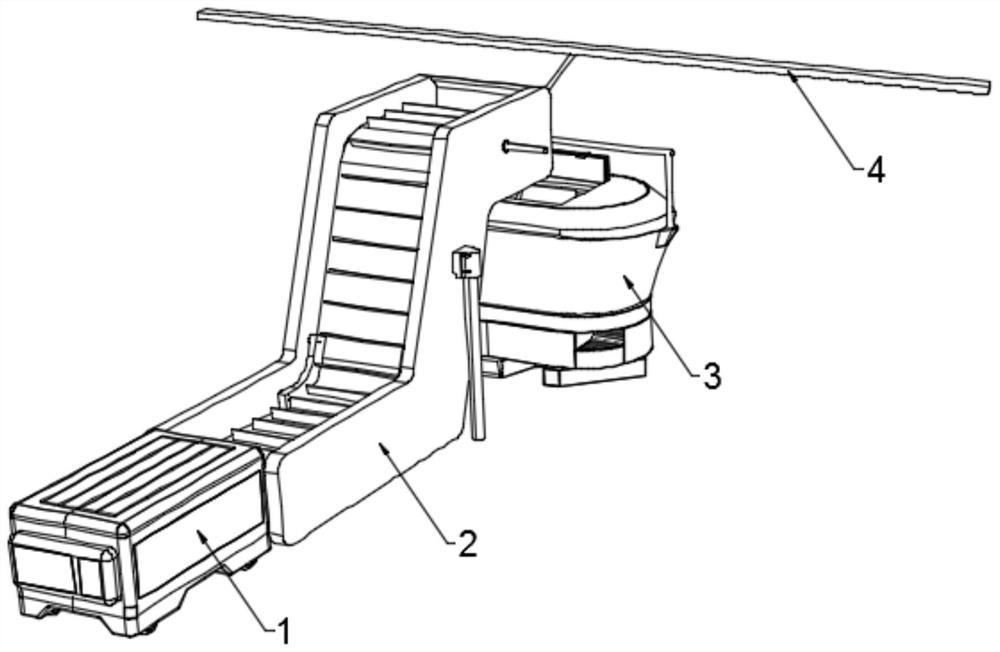

[0083] The embodiment of the present invention is realized like this, as figure 1 The intelligent processing and feeding production line of fully mixed ration shown includes:

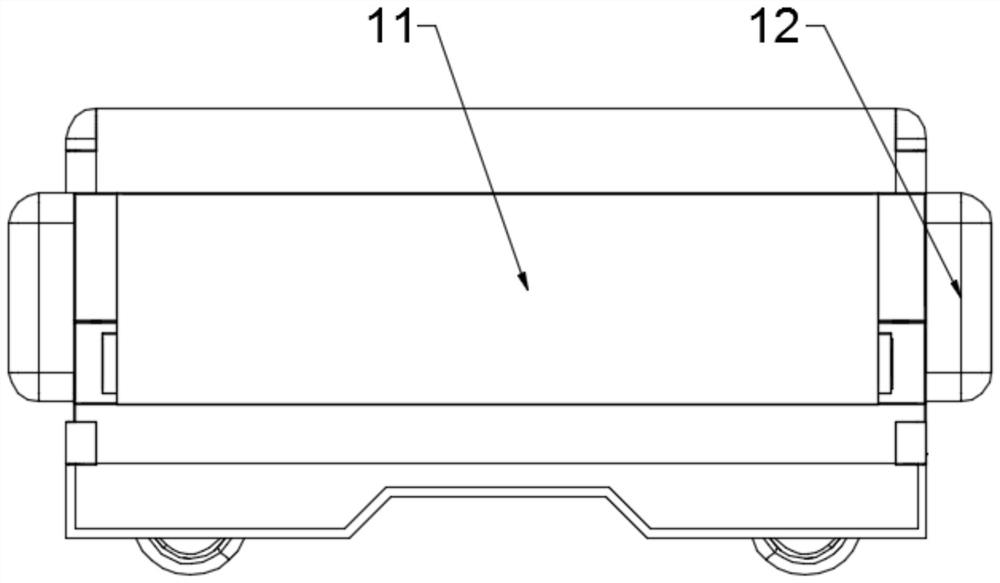

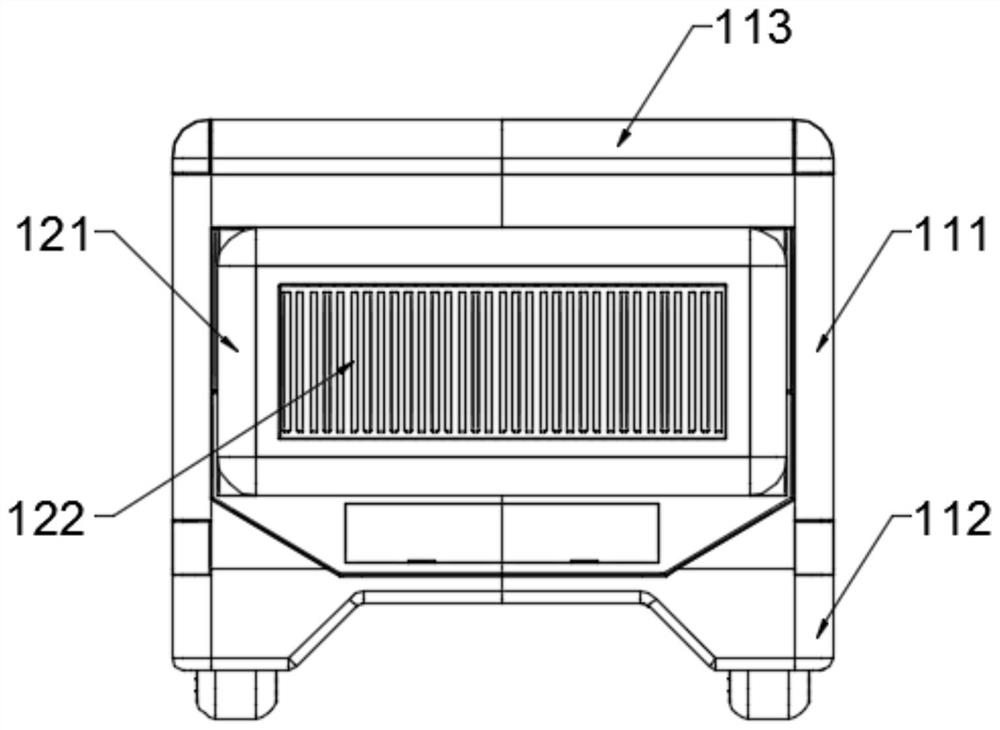

[0084] Pretreatment intelligent trolley 1, used to pretreat and transport the feed, and transport the pretreated feed to the position of the pasture conveyor;

[0085] Mixing and spreading machine 3, used to cut, stir, feed and recycle the feed;

[0086] Conveyor 2, which sends the feed processed by the intelligent trolley to the all-in-one mixing and spreading machine 3;

[0087] The wired electric track 4 is connected to the integrated stirring and spreading machine 3, and is used to guide the integrated stirring and spreading machine 3;

[0088] The control center is used to control the pretreatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com