Intelligent pollution prevention and control method used in starch sugar desalination process

A starch sugar and desalination technology, applied in the field of starch sugar desalination, can solve the problems of not taking into account the pollution of the membrane system, the difficulty of stable operation of the system, and the difficult application prospects, etc., to improve stability and efficiency, reduce material loss, Guaranteed effect of desalination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

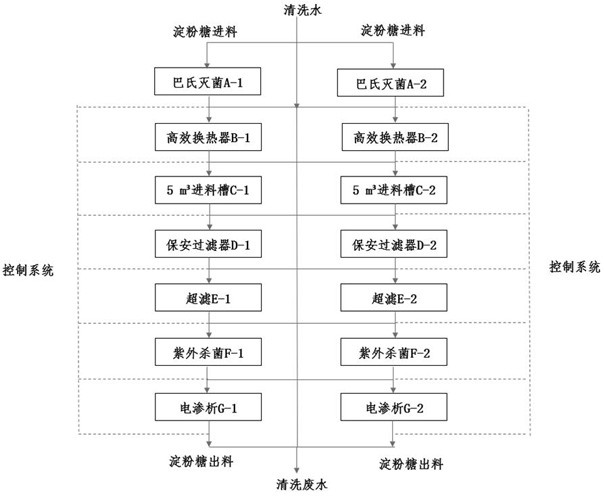

[0036] The starch sugar is first pasteurized at 75°C for 10 seconds, and then enters the high-efficiency heat exchanger, and the flow rate of the high-efficiency heat exchanger is 3m 3 / h, after heat exchange, the material is stable at 30°C and enters 5m 3 After 20 minutes of settlement, most of the impurities can settle at the bottom, which effectively reduces the pressure of the subsequent processing unit. 5m 3 The supernatant of the feeding tank is pumped to the security filter, and the flow rate of the security filter is controlled to be 3 m 3 / h, the pressure difference between the inlet and outlet is 0.2 Mpa, the pore size of the filter core of the security filter is 0.2µm PP cotton, after being filtered by the security filter, the starch sugar enters the ultrafiltration unit. The fresh water effluent flow rate of the ultrafiltration system is 3m 3 / h, concentrated water outlet flow rate is 8 m 3 / h, the wall thickness is 0.02 μm, the inner diameter of the membrane f...

Embodiment 2

[0038] The starch sugar is first pasteurized at 80°C for 10 seconds, and then enters the high-efficiency heat exchanger, and the flow rate of the high-efficiency heat exchanger is 4m 3 / h, after heat exchange, the material is stable at 30°C and enters 5m 3 After 20 minutes of settlement, most of the impurities can settle at the bottom, which effectively reduces the pressure of the subsequent processing unit. 5m 3 The supernatant of the feeding tank is pumped to the security filter, and the flow rate of the security filter is controlled to be 4 m 3 / h, the pressure difference between the inlet and outlet is 0.3 Mpa, the pore size of the filter element of the security filter is 0.3 µm PP cotton, after being filtered by the security filter, the starch sugar enters the ultrafiltration unit. The fresh water effluent flow rate of the ultrafiltration system is 3m 3 / h, concentrated water outlet flow rate is 8 m 3 / h, the wall thickness is 0.02 μm, the inner diameter of the membra...

Embodiment 3

[0040] The starch sugar is first pasteurized at 85°C for 10 seconds, and then enters the high-efficiency heat exchanger, and the flow rate of the high-efficiency heat exchanger is 4m 3 / h, after heat exchange, the material is stable at 30°C and enters 5m 3 After 20 minutes of settlement, most of the impurities can settle at the bottom, which effectively reduces the pressure of the subsequent processing unit. 5m 3 The supernatant of the feeding tank is pumped to the security filter, and the flow rate of the security filter is controlled to be 6 m 3 / h, the pressure difference between the inlet and outlet is 0.4 Mpa, the pore size of the filter core of the security filter is 0.4 µm PP cotton, after being filtered by the security filter, the starch sugar enters the ultrafiltration unit. The fresh water effluent flow rate of the ultrafiltration system is 3m 3 / h, concentrated water outlet flow rate is 8 m 3 / h, the wall thickness is 0.02 μm, the inner diameter of the membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com