A water meter automatic assembly system and method

An automatic assembly and water meter technology, applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems that the technical accuracy time cannot meet the water meter assembly requirements, the product qualification rate is reduced, and the ultrasonic water meter cannot meet the assembly requirements, etc., to achieve Improve assembly accuracy and assembly efficiency, improve assembly accuracy, and avoid falling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

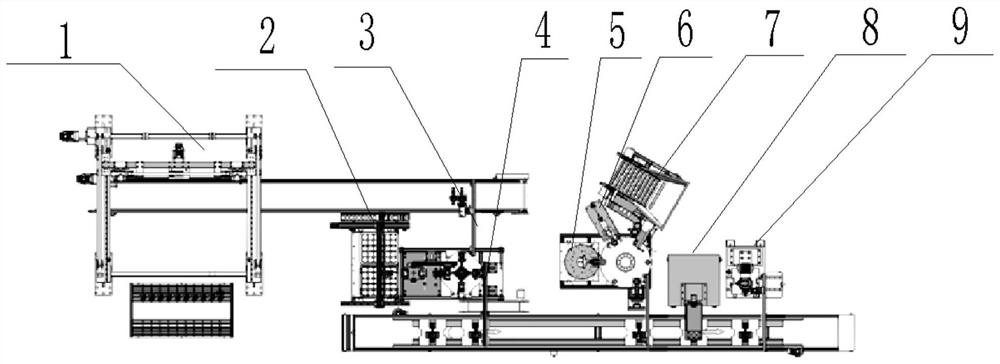

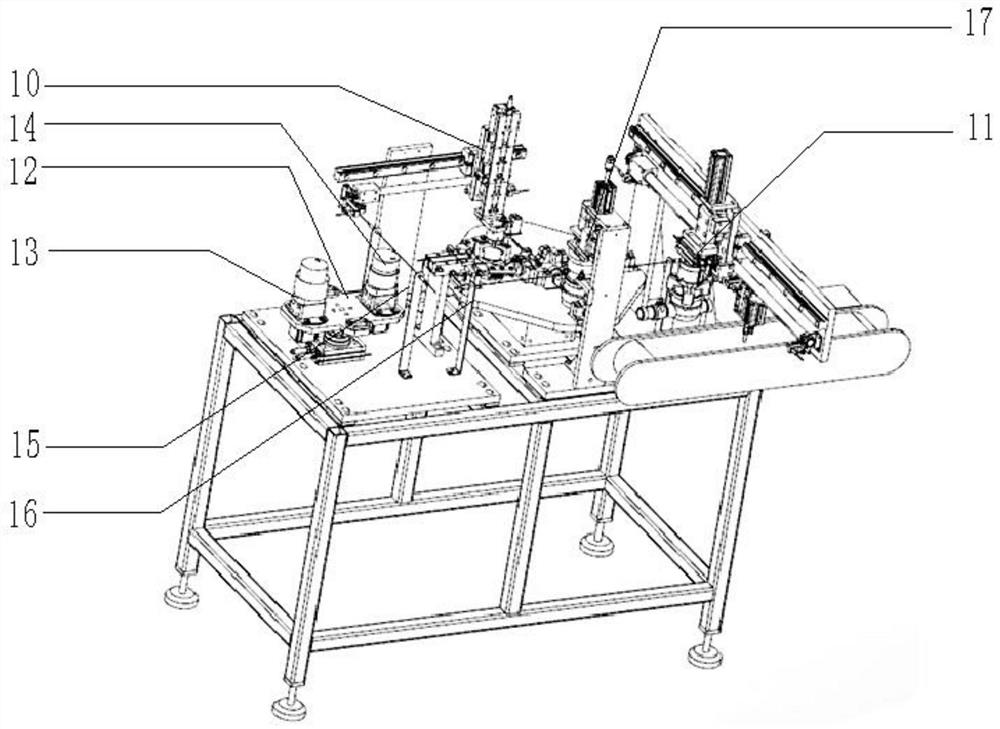

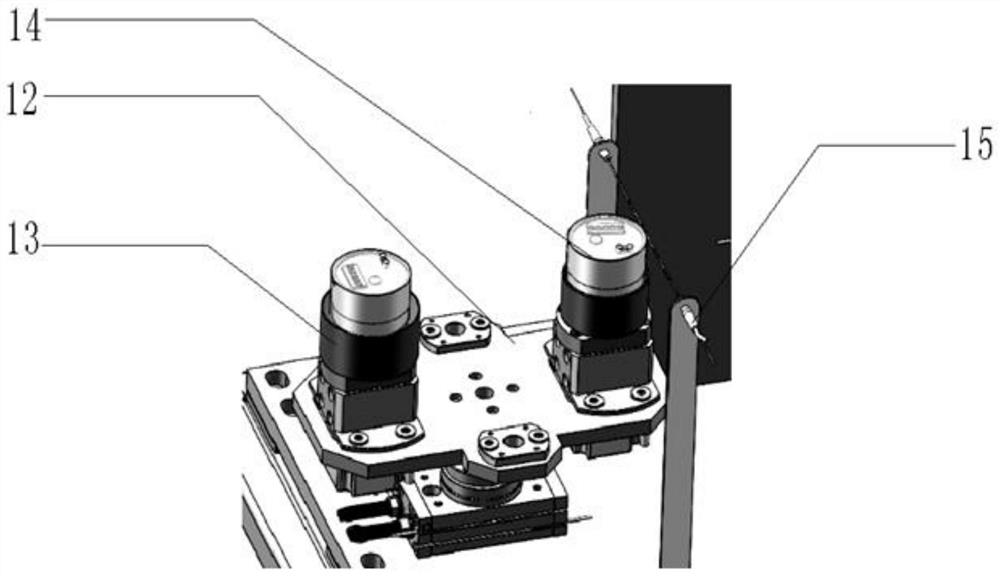

[0055] as Figure 1-7 As shown, embodiment 1 of the present disclosure provides an automatic assembly system for water meters, comprising:

[0056] Movement feeding mechanism 2, copper shell feeding mechanism 1, copper shell clamping mechanism 3, first component clamping mechanism 4, gasket feeding mechanism 6, lens feeding mechanism 5 and mask feeding mechanism 7;

[0057] Movement feeding mechanism 2 includes a movement clamping manipulator 10 (i.e., the first mechanical arm), the copper shell feeding mechanism includes a copper shell feeding robot arm, for simultaneously clamping a row (10) copper shells, according to the specified action to the copper shell transmission belt, the copper shell moves with the conveyor belt to the copper shell manipulator, after positioning, the copper shell manipulator clips the copper shell and puts it in the first copper shell to be assembled station.

[0058] Copper shell clamping mechanism 3 includes a second robotic arm, by the first robotic...

Embodiment 2

[0086] as Figure 8 As shown, embodiment 2 of the present disclosure provides a water meter automatic assembly method, using the water meter automatic assembly system described in the first aspect of the present disclosure, comprising the following process:

[0087] S1: The gripper of the copper shell automatic feeding robot arm (three-axis robot arm) simultaneously clips a row (10) copper shells, and places them in the copper shell transmission belt according to the specified action;

[0088] The copper shell moves with the conveyor belt under the copper shell manipulator, and after positioning, the copper shell manipulator clips the copper shell and places it in the copper shell to be assembled station 1 (this action is then repeated).

[0089] S2: The gripper of the movement automatic feeding robot arm (three-axis robot arm) takes a movement and places it in the pending position - the movement to be assembled1 (this action is then repeated).

[0090] S3: Movement rotary positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com