Automatic welding mechanism for stamping parts

A technology for automatic welding and stamping parts, applied in the field of stamping parts welding, can solve the problems that affect the service life of workpieces, rivets are prone to bending, and the surface shape of workpieces is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

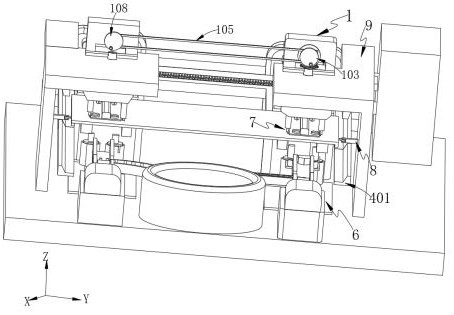

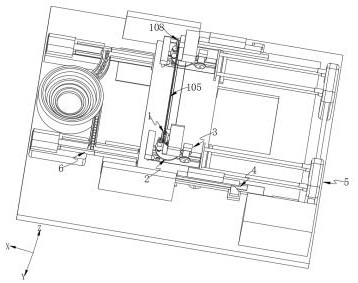

[0084] like Figure 1-3 As shown, an automatic welding mechanism for stamping parts, including:

[0085] drive unit 1;

[0086] A switching unit 2, the switching unit 2 is arranged under the driving unit 1, and is used for drilling and punching the riveting part;

[0087] A preload unit 3, which is arranged on one side of the drive unit 1, and is used to preload and guide the small metal plate;

[0088] A bending unit 4, the bending unit 4 is arranged on one side of the pretensioning unit 3 along the -X direction, and is used to bend the large metal plate;

[0089] Pushing unit 5, described pushing unit 5 is arranged on the side of described bending unit 4;

[0090] A nailing unit 6, the nailing unit 6 is arranged below the switching unit 2;

[0091] A welding unit 7, the welding unit 7 is arranged on one side of the pretensioning unit 3 along the +X direction;

[0092] When working, two metal plates of different sizes are pushed by the pushing unit 5. The large metal pla...

Embodiment 2

[0142] like figure 1 , Image 6 , Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0143] The two sides inside the support 9 are provided with guide units 8, the guide unit 8 includes a guide plate 801 connected to one side of the support 9, a guide roller 802 connected to one side of the guide plate 801, and the guide roller 802 guides and fixes the large metal plate. It can prevent the position deflection of the large metal plate during processing, and further improve the processing accuracy.

Embodiment 3

[0145] like Figure 1-3 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment three and embodiment one, the difference of embodiment two is:

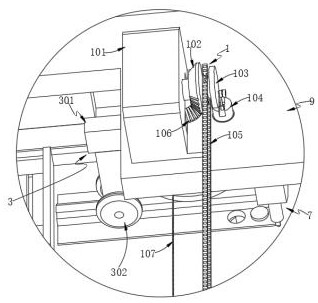

[0146] The first transmission chain 105 is set on the first helical gear 102 side, so that the crank transmission mechanism 103 can drive the second crank transmission mechanism 108 to rotate during the rotation process, and the sprocket 207 is set on the second helical gear 106 side, so that the second helical gear 106 side is set. The second helical gear 106 can drive the second transmission chain 107 to rotate during the rotation process, so that a plurality of small metal plates and large metal plates can be riveted and welded at one time, and the degree of automation is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com