Production process of semi-solid wheel

A production process, solid wheel technology, applied in the field of semi-solid wheel production process, can solve problems such as poor shock absorption capacity, low safety, easy to burn workers, etc., achieve good wear resistance, improve product quality, and improve safety Effects on Work Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

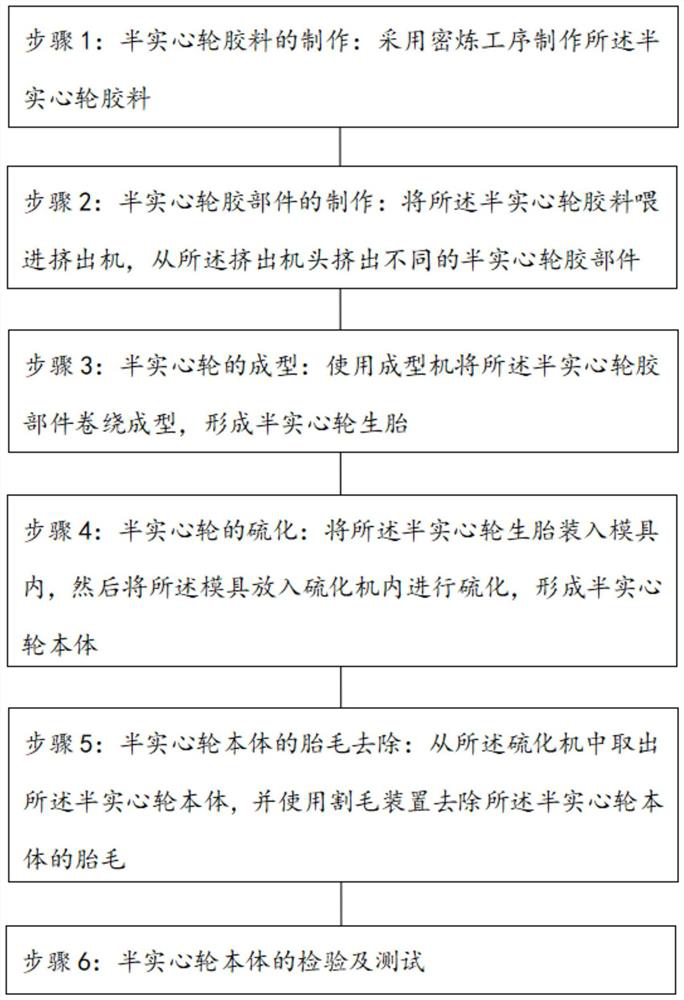

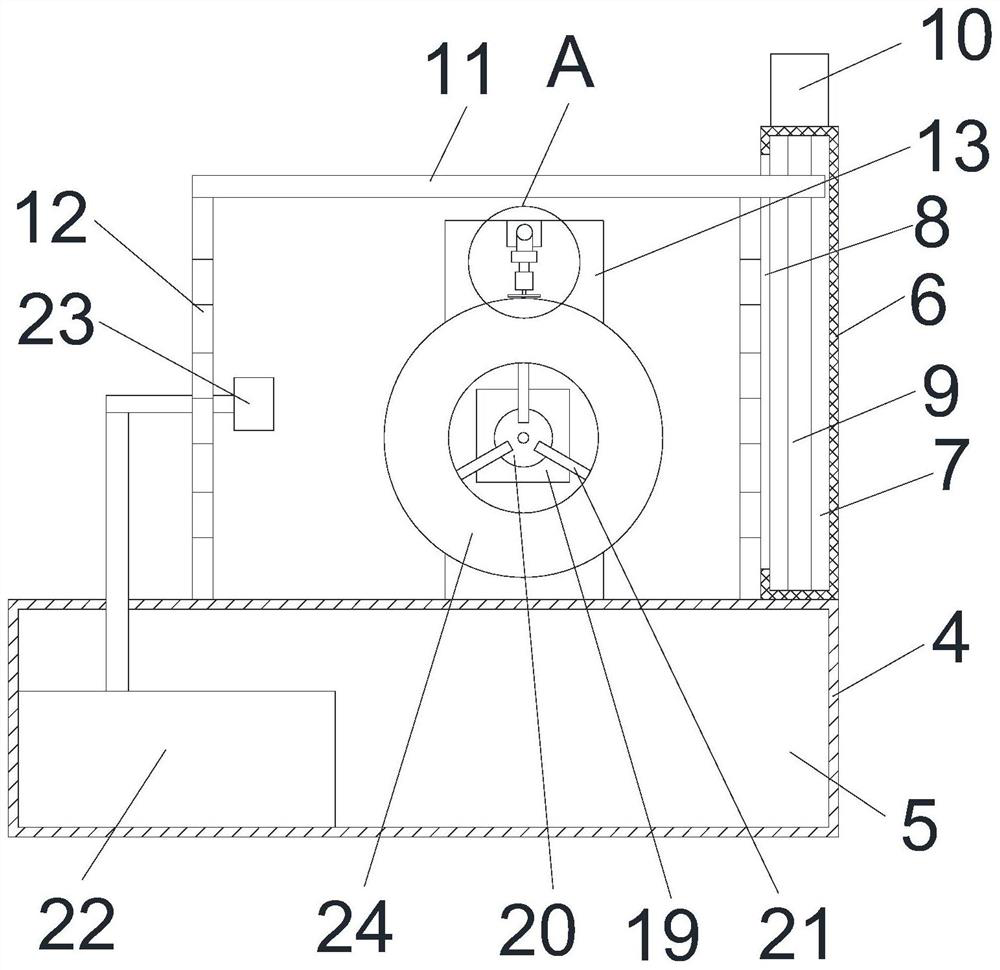

[0044] The embodiment of the present invention provides a kind of production technology of semi-solid wheel, such as Figure 1-Figure 6 shown, including the following steps:

[0045] Step 1: Production of the semi-solid wheel rubber material: making the semi-solid wheel rubber material through a banburying process;

[0046] Step 2: making semi-solid wheel rubber parts: feeding the semi-solid wheel rubber material into an extruder, extruding different semi-solid wheel rubber parts from the extruder head;

[0047] Step 3: Forming of the semi-solid wheel: using a forming machine to wind the semi-solid wheel rubber parts to form a semi-solid wheel tire;

[0048] Step 4: vulcanization of the semi-solid wheel: putting the semi-solid wheel tire into a mold, and then putting the mold into a vulcanizer for vulcanization to form the semi-solid wheel body 24;

[0049] Step 5: lanugo removal of the semi-solid wheel body 24: take out the semi-solid wheel body 24 from the vulcanizer, and us...

Embodiment 2

[0053] On the basis of the above-mentioned Example 1, in the step 1, the banburying process is: raw materials such as high-quality natural rubber, wear-resistant fiber, synthetic rubber, nano-calcium carbonate, nano-graphite, oil, additives, accelerators, etc. Mix them together, and then put them into a banbury mixer for banbury processing, so as to make the semi-solid wheel compound.

[0054] The working principle and beneficial effects of the above technical scheme are as follows: during banburying, raw materials such as high-quality natural rubber, wear-resistant fiber, synthetic rubber, nano-calcium carbonate, nano-graphite, oil, additives, accelerators, etc. need to be mixed together first, and then Put it into the internal mixer for internal mixing processing to produce semi-solid wheel rubber. The rubber used for each rubber part in the semi-solid wheel has specific properties. The composition of the rubber depends on the performance of the semi-solid wheel. requirement...

Embodiment 3

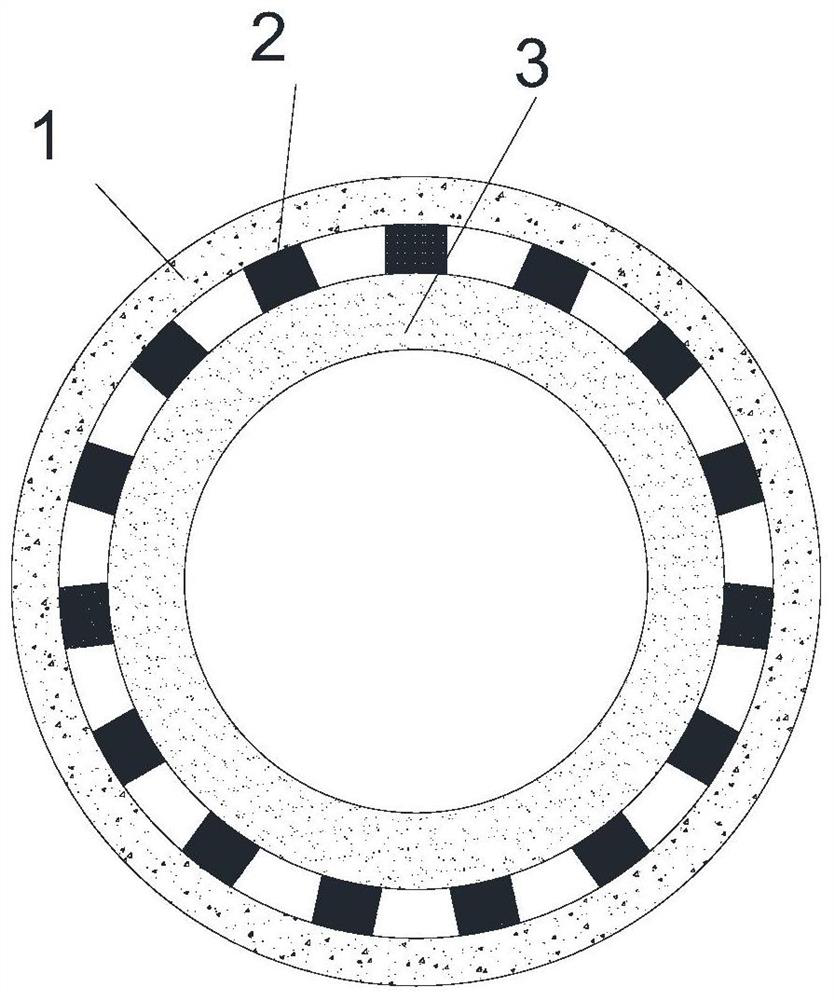

[0056] On the basis of embodiment 1 or 2, in the step 2, the semi-solid wheel rubber part includes a rubber layer and a rubber block.

[0057] The working principle and beneficial effects of the above-mentioned technical solution are as follows: the rubber part of the semi-solid wheel includes a rubber layer and a rubber block, and both the rubber layer and the rubber block are extruded from different positions of the extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com