A method for preparing building aggregates with domestic waste incineration slag

A technology for domestic waste incineration and slag, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of structural defects, durability defects, and high safety risks, so as to improve particle strength, reduce Pore, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

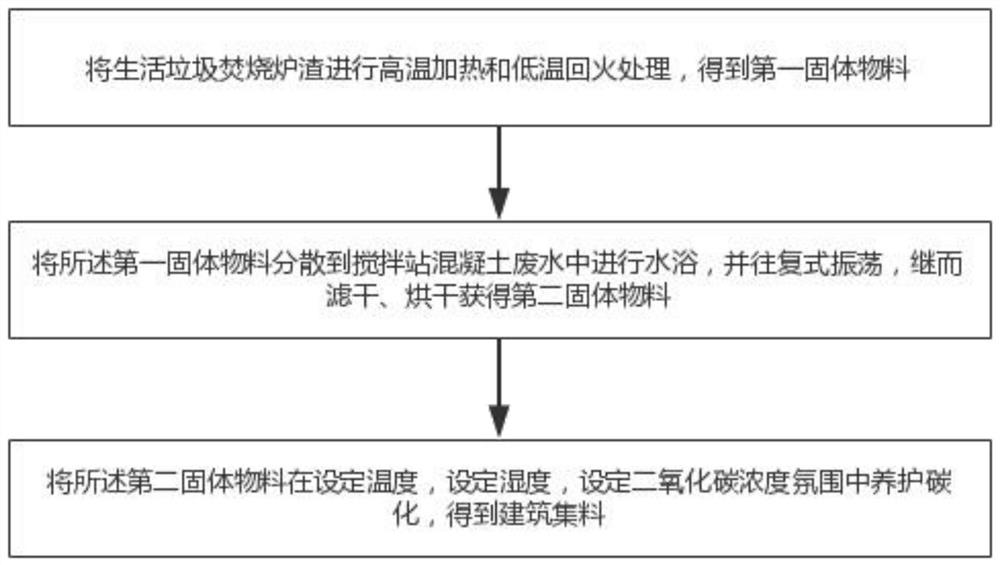

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment provides a method for preparing a novel high-quality aggregate, comprising the following steps:

[0056] S01. Use a vibrating screen to pass the domestic waste incinerator slag through a 20mm sieve as it is, use a jaw crusher to crush the domestic waste incinerator slag larger than 20mm as it is (after removing metal impurities), and take out the crushed aggregates and mix them to a life size smaller than 20mm. From the waste incineration slag as it is, domestic waste incineration slag having a size of less than 20 mm described in this specification was obtained.

[0057] S02. Place the domestic waste incineration slag smaller than 20mm in a crucible, place the crucible in the muffle furnace, and heat up from room temperature to 680-750°C at a rate of 10-30°C / min, and keep the temperature for 1-2h after , The domestic waste incineration slag is immediately taken out from the furnace, and the concrete waste water of the mixing station is extremely ...

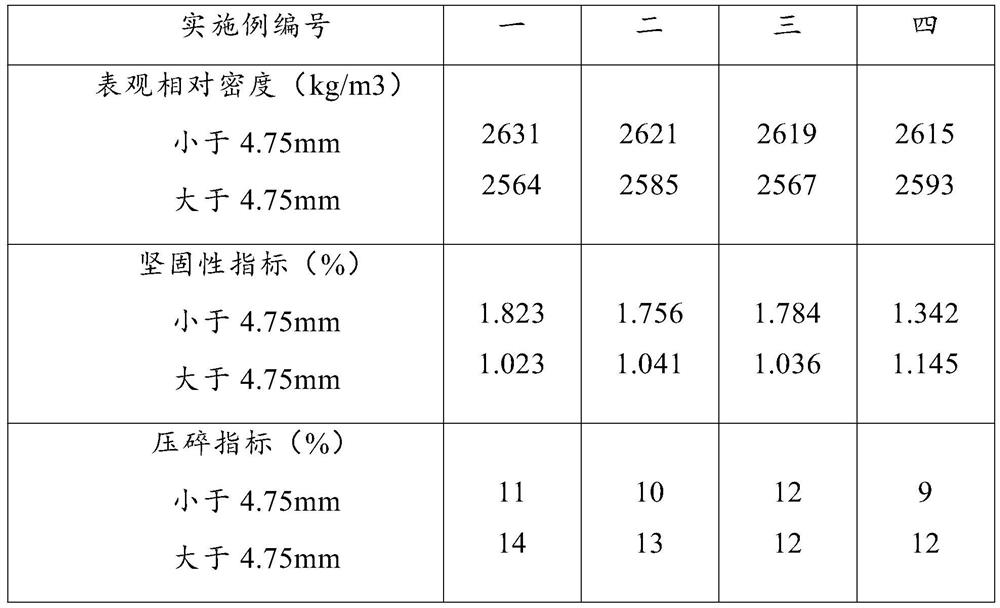

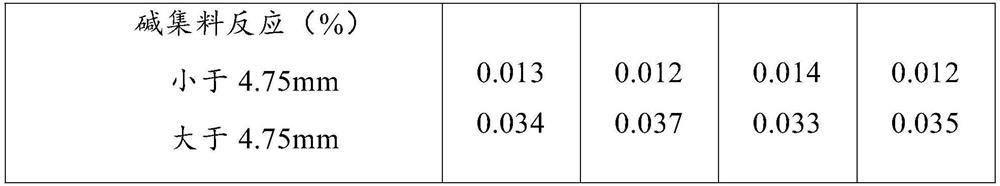

Embodiment 2

[0062] As another embodiment of the present invention, different from the first embodiment, in step S05 of this embodiment, the curing temperature is (40±1)° C., the relative humidity is (40±5)%, and the CO2 concentration is (70 ±5)%, the curing time is 5d.

Embodiment 3

[0064] As another embodiment of the present invention, different from the first embodiment, in step S05 of this embodiment, the curing temperature is (60±1)° C., the relative humidity is (60±5)%, and the CO2 concentration is (50 ±5)%, the curing time is 2d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com