Method for detecting concave-convex amount of aircraft assembly fastener

A technology for aircraft assembly and detection methods, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of high computing power requirements of computing platforms, inaccurate extraction of high and low points, and narrow data coverage areas. Battery life, beneficial to miniaturization, and the effect of large data coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

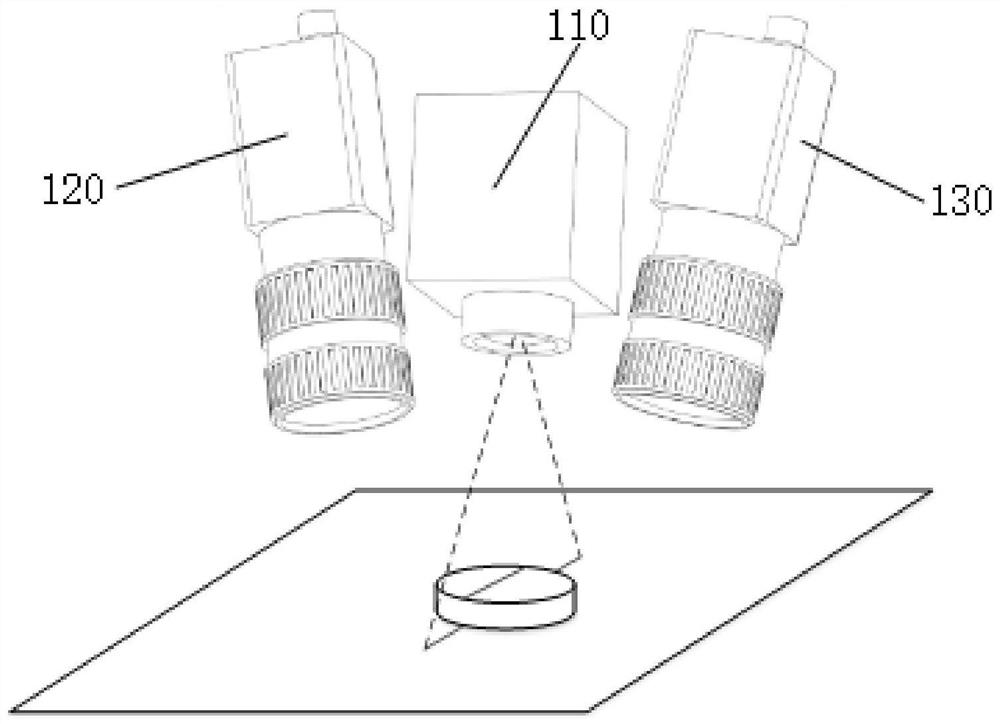

[0046] like Figure 1-3 As shown, the present embodiment provides a method for detecting unevenness of aircraft assembly fasteners, comprising the following steps:

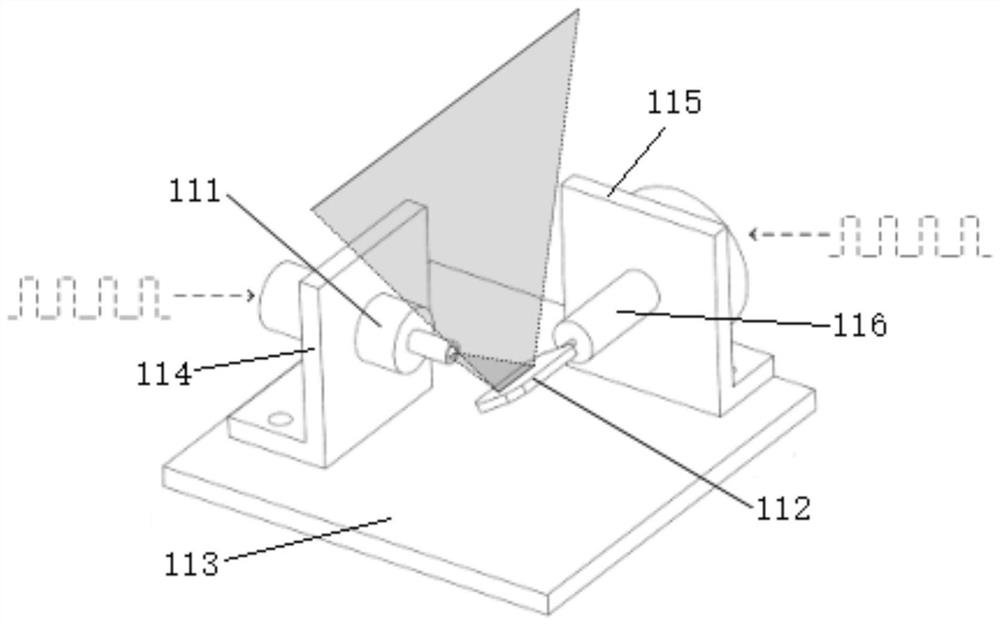

[0047] Step S1: build a detection device, the detection device includes a scanner 110, the first camera 120 and the second camera 130 are respectively arranged on both sides of the scanner 110, the scanner 110 includes a line laser 111 and a one-dimensional vibrating mirror 112, the one-dimensional vibrating mirror 112 is used to reflect the linear laser light projected by the line laser 111 to the surface of the fastener under test;

[0048] Step S2: Output a synchronous square wave signal to the line laser 111 and the one-dimensional vibrating mirror 112 to change the rotation angle of the one-dimensional vibrating mirror 112, the one-dimensional vibrating mirror 112 rotates in a stepwise manner, and the line laser 111 lights up once for each rotation angle , so that the reflected light scans the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com