Patents

Literature

36results about How to "Avoid false matches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

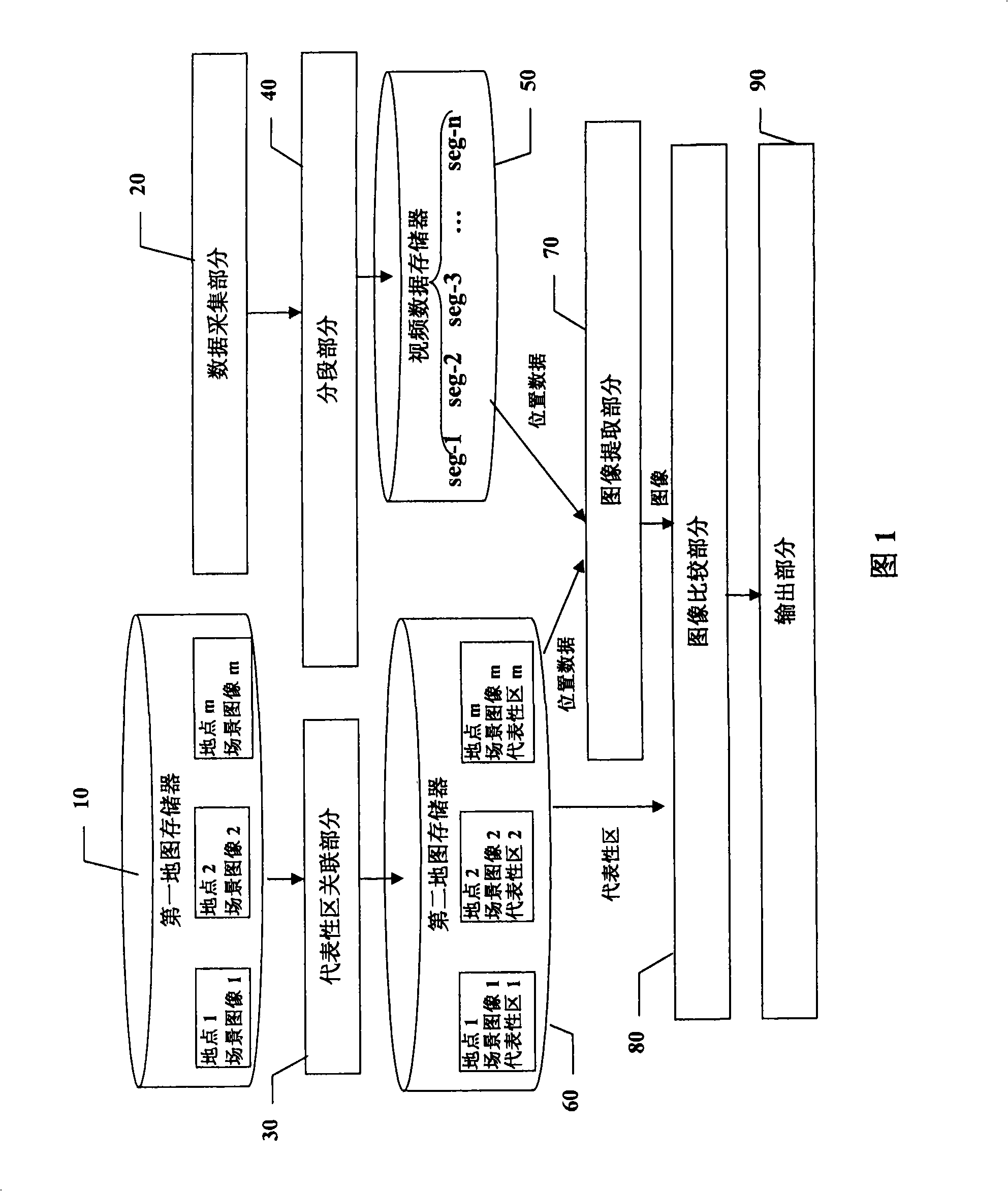

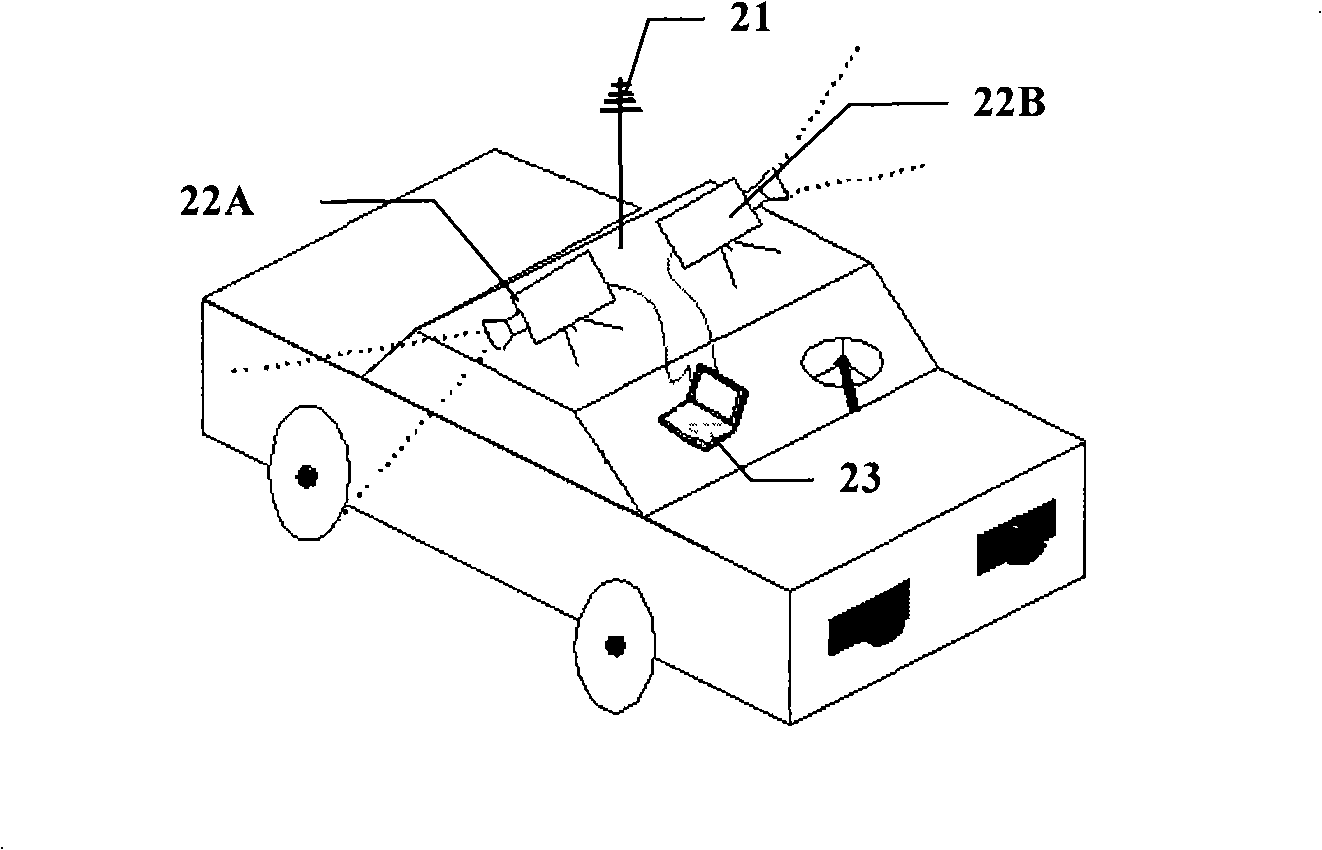

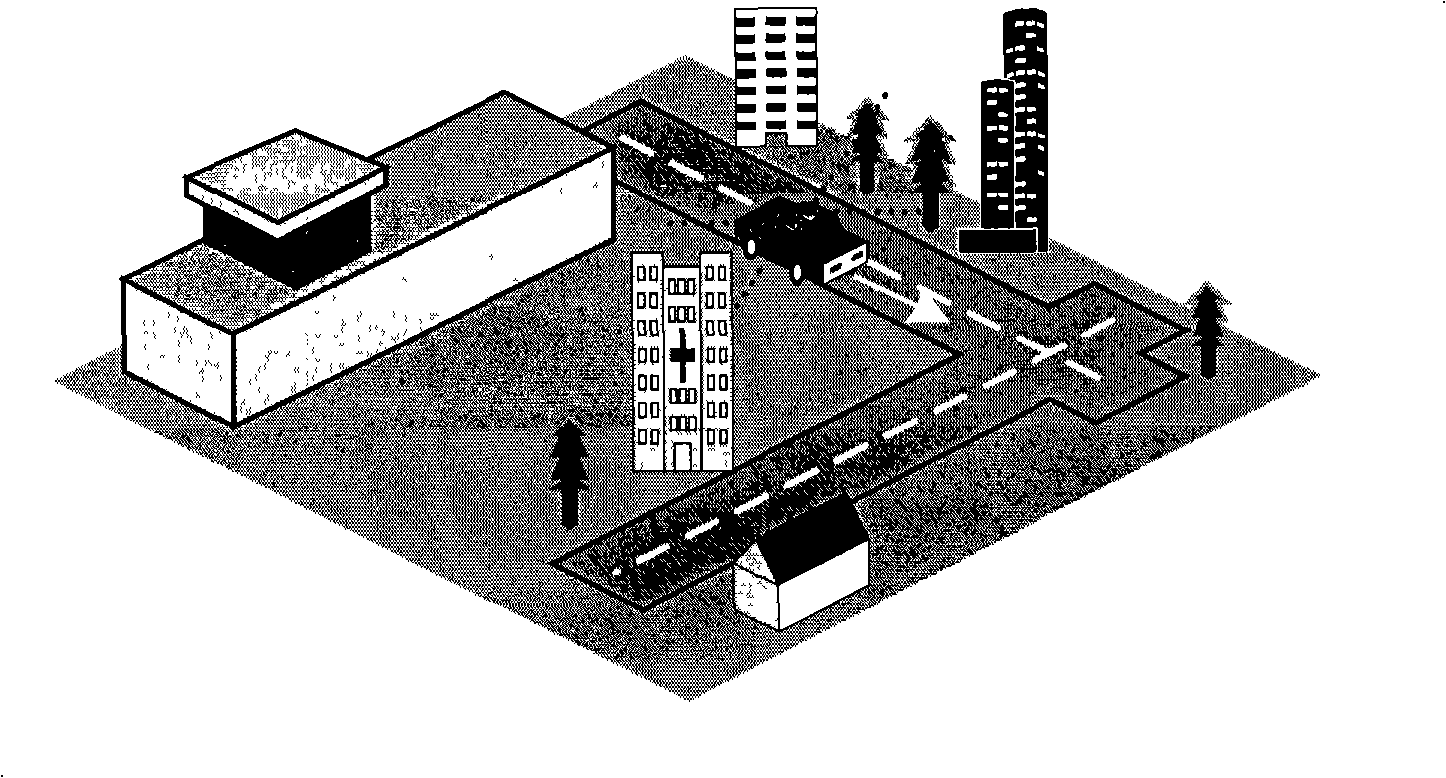

Method and equipment for updating map data

InactiveCN101275854AFast updateAvoid heavy computationInstruments for road network navigationCharacter and pattern recognitionData needsComputer science

The invention discloses a method and a device of updating map data, wherein, each place in the map not only is related to geographic data, but also is related to at least one scene image pictured in the place. The method comprises: collecting video data and the geographic data representing location of the place in each place; extracting a representative area representing the place from the scene image based on predetermined standards and making the representative area related to the place; extracting an image pictured in the place from the video data based on the location of the place; matching the representative area and the extracted image and generating a matching result; in the condition that the matching result shows the map data need to be updated, making the image matched with the representative area as an update image to update the scene image. Making use of the invention can rapidly update the map data, so as to provide up-to-date geographic data for users.

Owner:NEC (CHINA) CO LTD

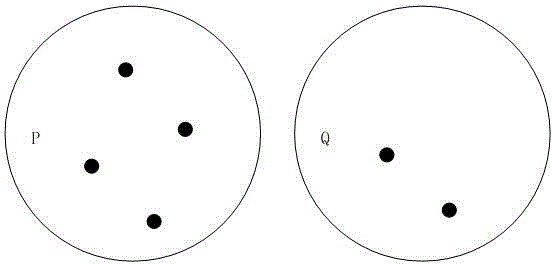

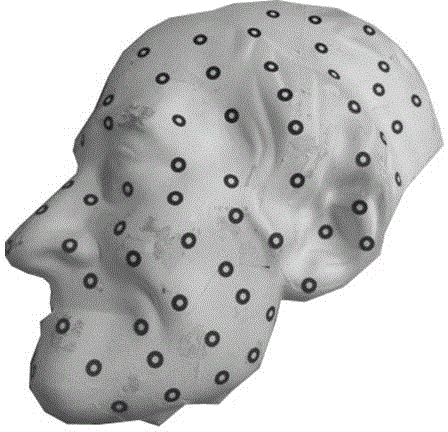

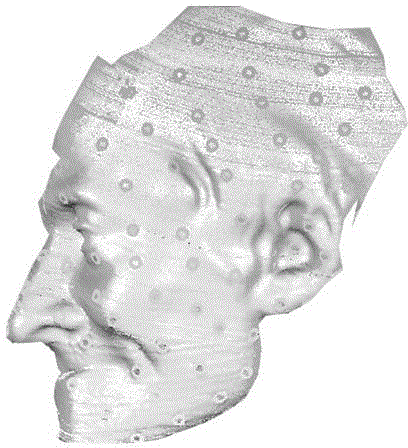

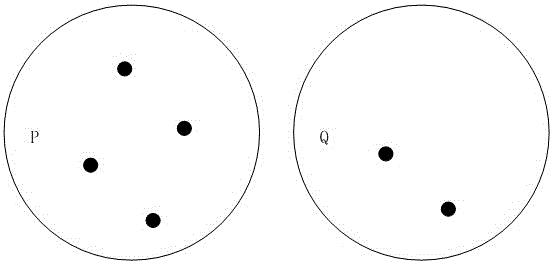

Three-dimensional mark point matching method for point cloud registration and three-dimensional scanning method

ActiveCN104406538ACalculation results are stableAvoid false matchesImage analysisPhotogrammetry/videogrammetryPoint cloudThree dimensional measurement

The invention discloses a three-dimensional mark point matching method for point cloud registration and a three-dimensional scanning method, and belongs to the field of three-dimensional measurement technologies. The three-dimensional mark point matching method comprises the following steps: acquiring three-dimensional coordinate sets P and Q of two visual-angle mark points through a binocular camera; calculating energy of candidate matching points, which are in regard to a point p in the set P, in the set Q; selecting a certain updating strategy according to the 'uniqueness' constraint and the 'spatial feature unchange' constraint; if the matching points found out are all highest in energy and meet a threshold value condition and a restraint condition, ending iteration, otherwise, returning to iteration until the matching points meeting the conditions are found; calculating Euclid transformation according to the matching points, and performing splicing of multi-view point cloud. Compared with other mark point splicing methods, the splicing method has the advantages that the operation is simpler, the number of iteration times is small, 1-2 times of iteration are performed generally, the splicing time is greatly shortened, and a splicing result is stable and reliable under a condition of enough overlapping regions; the three-dimensional mark point matching method can be widely applied to multi-view point cloud data splicing acquired by various sets of measurement equipment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

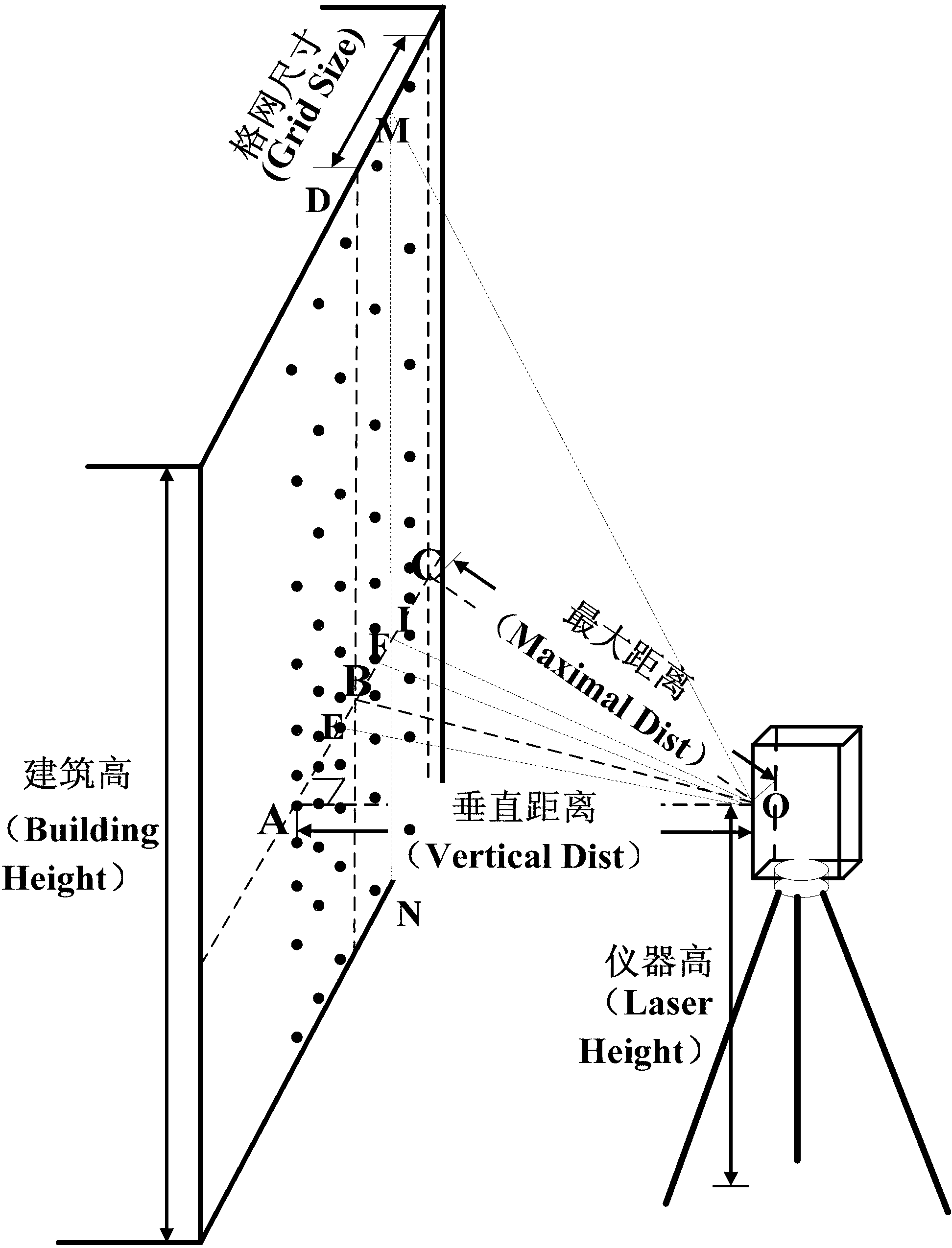

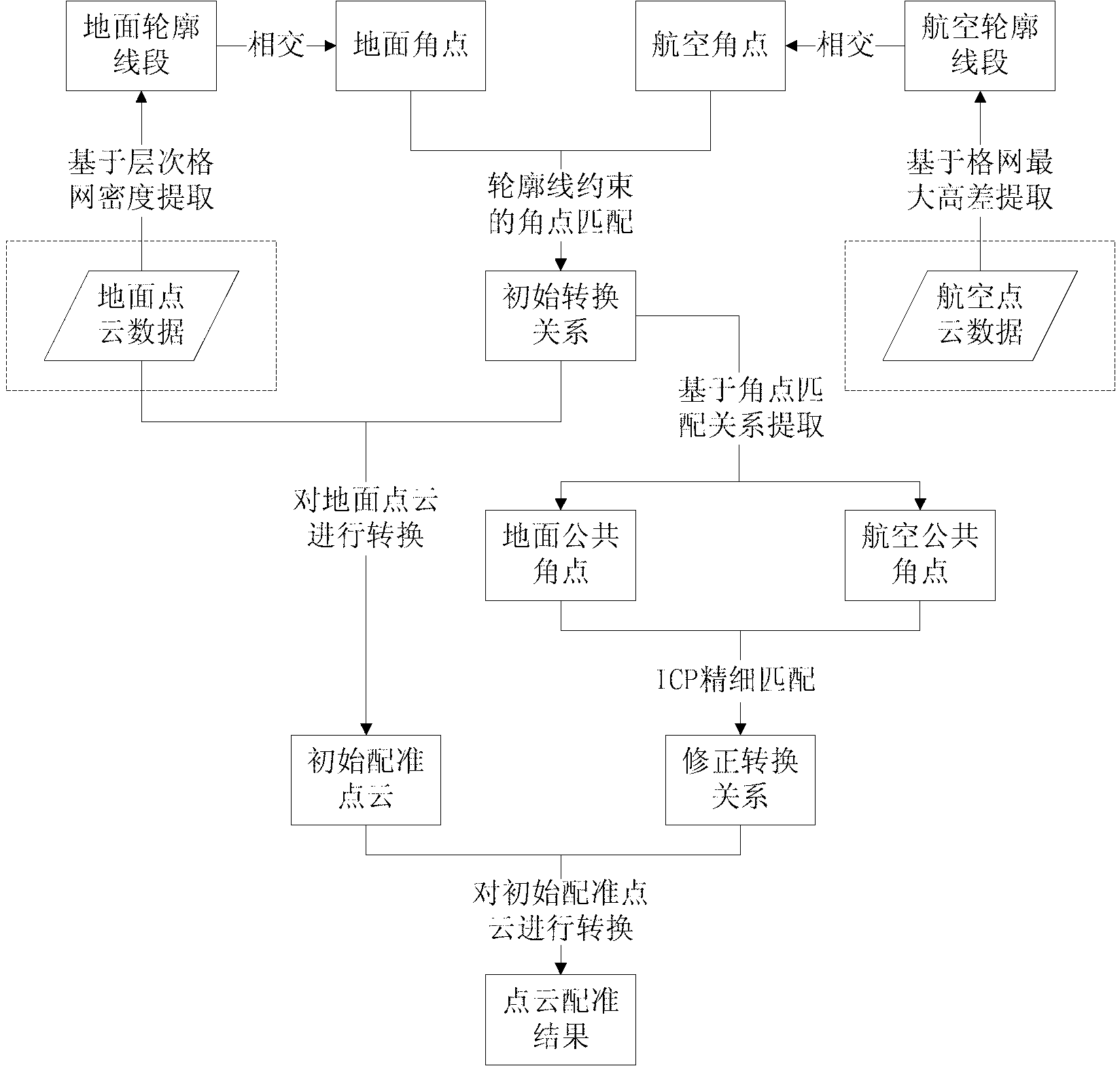

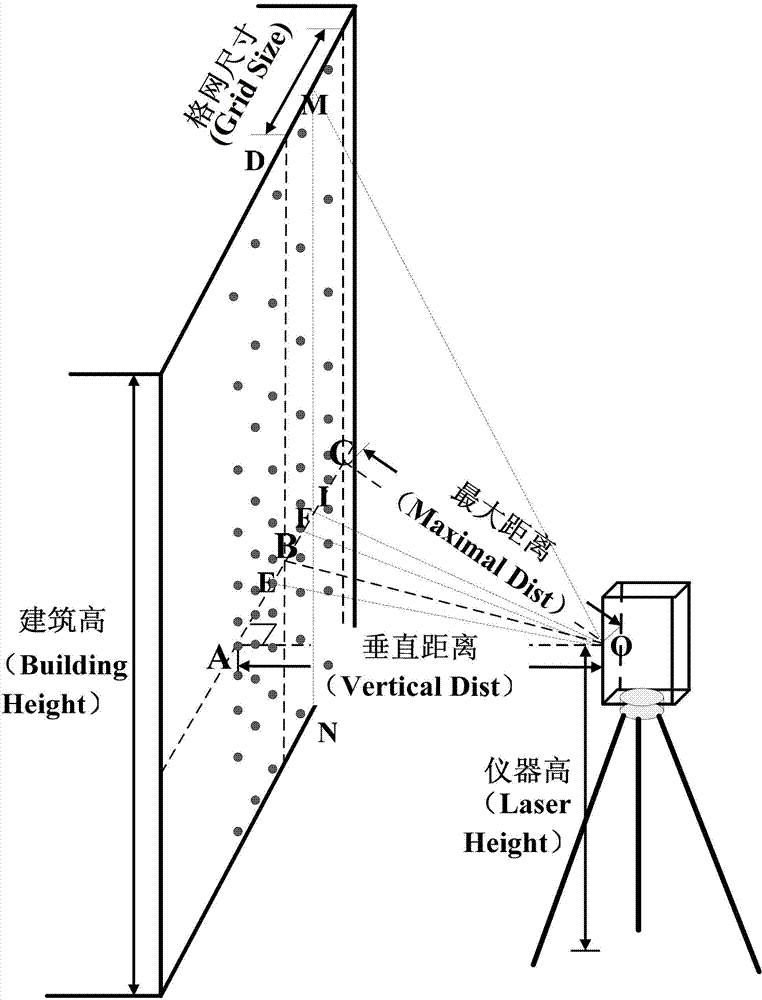

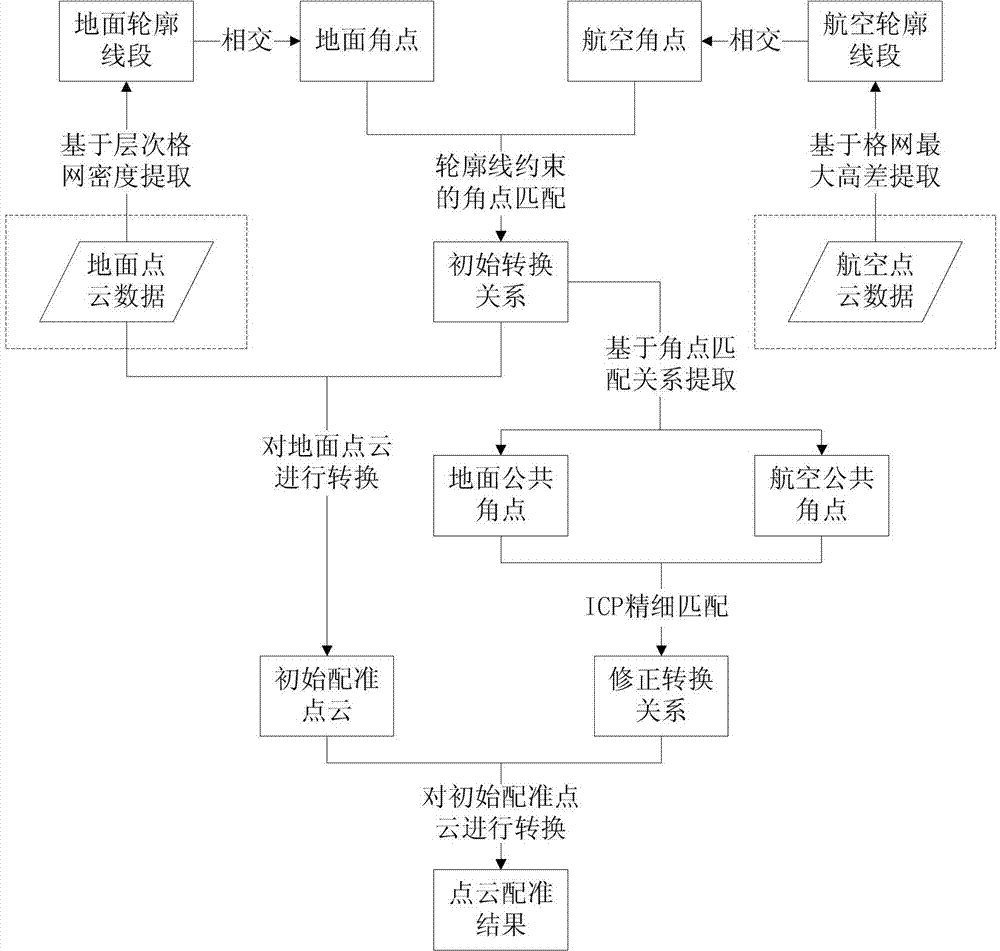

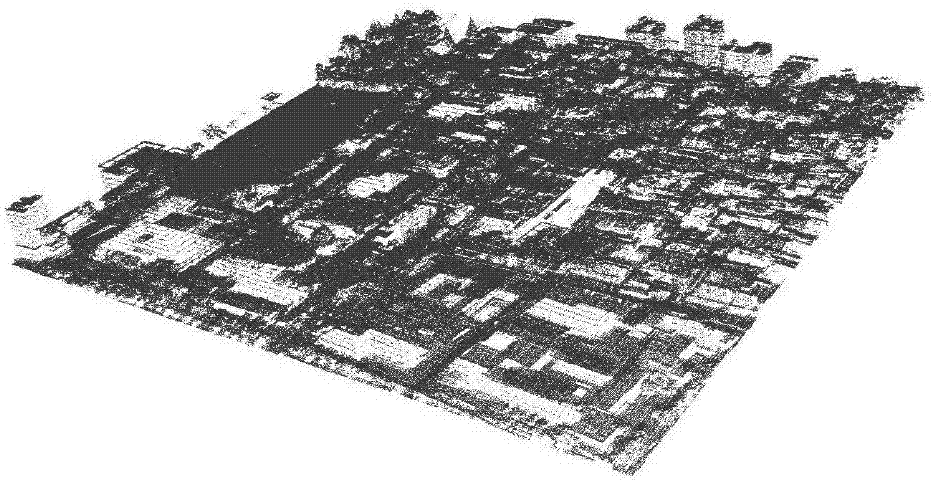

Automatic registration method of aviation and ground LiDAR data based on building contour constraint

InactiveCN103020966AReliability advantageAdvantage AccuracyImage analysisWave based measurement systemsAviationAngular point

Disclosed is an automatic registration method of aviation and ground LiDAR data based on building contour constraint. The method includes firstly extracting building contours or aviation contours and ground contours for short from aviation and ground LiDAR data; extracting building angular points or aviation angular points and ground angular points for short from the aviation contours and the ground contours; taking the matching degree between the aviation contours and the ground contours as constraint, calculating initial transfer matrixes between the aviation angular points and the ground angular points, and obtaining initial matching angle dot pairs; finally, calculating correction transfer matrixes between the initial matching angle dot pairs by using an iterative closest point (ICP) algorithm, and converting ground dot cloud data to be matched through the initial transfer matrixes and the correction transfer matrixes successively to achieve automatic high-precision registration of the aviation and ground LiDAR data. The method has great advantages in registration reliability and accuracy with contour lines serving as constraint; and simultaneously, based on LiDAR data to be matched and reference LiDAR data, accuracy registration between the aviation and ground LiDAR data can be achieved without other auxiliary data.

Owner:NANJING UNIV

A method of building a three-dimensional map

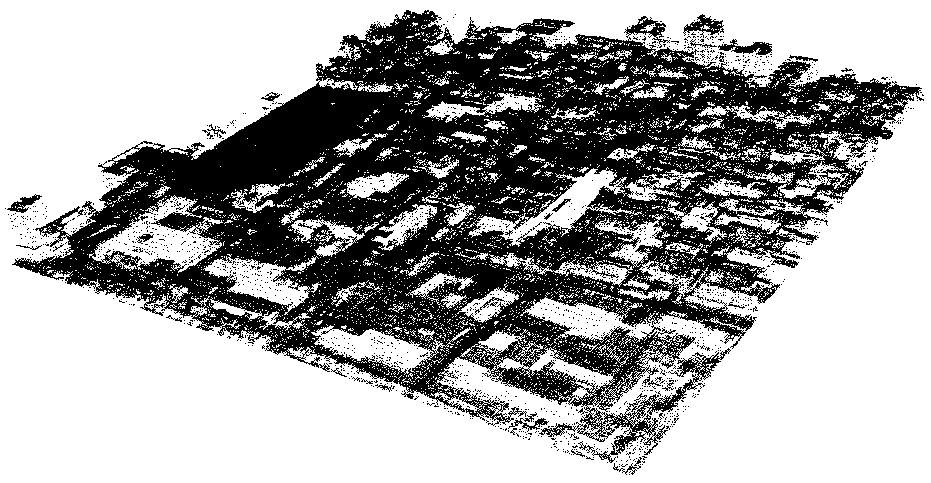

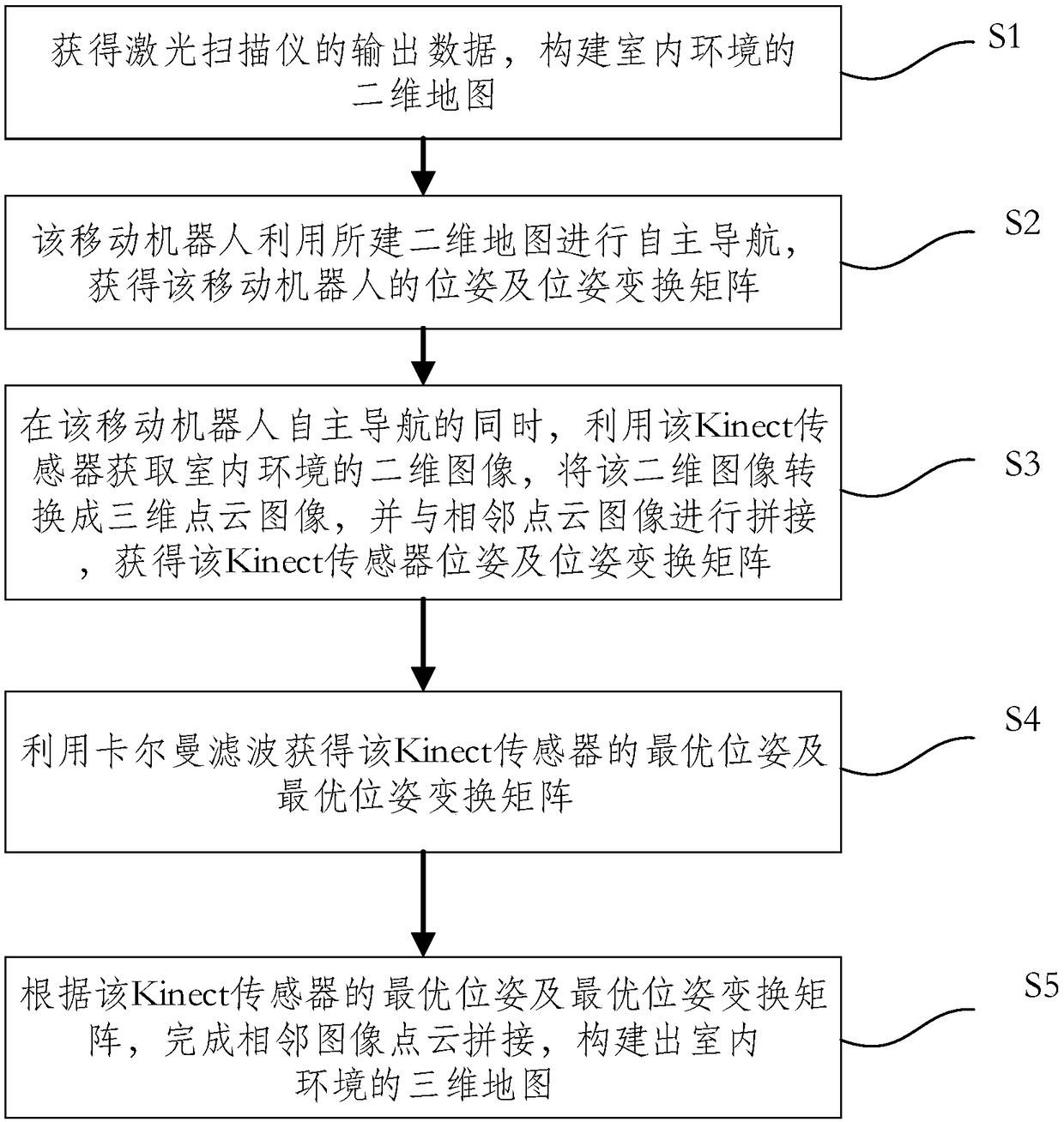

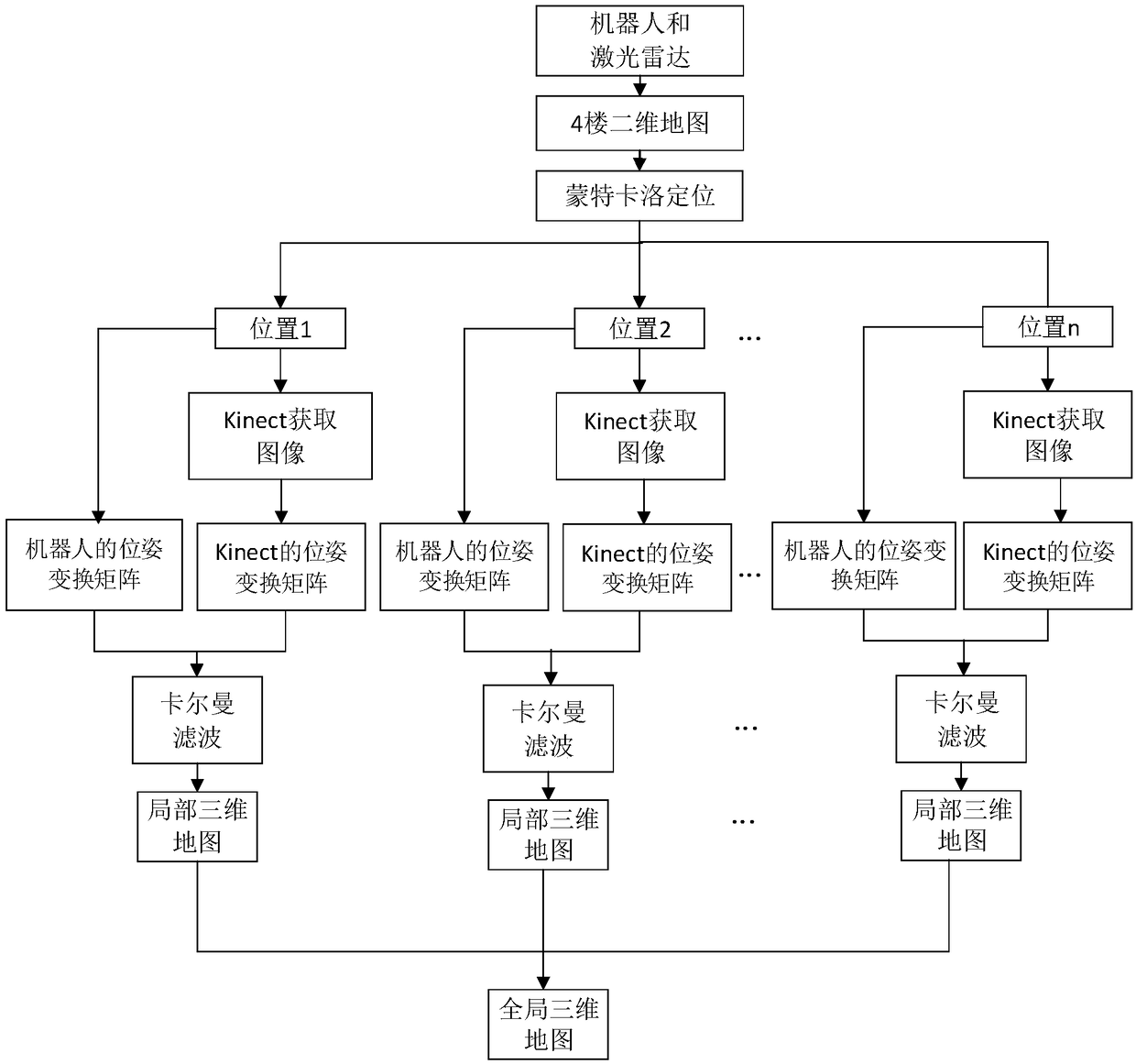

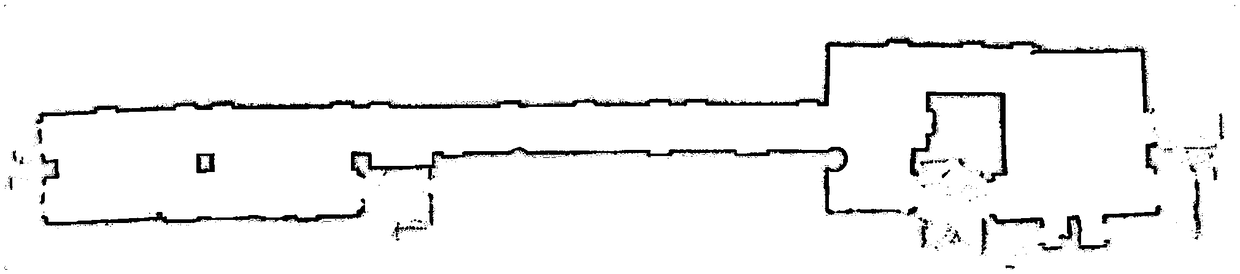

PendingCN109087393AImplement the buildHigh positioning accuracyImage enhancementImage analysisPoint cloudLaser scanning

The embodiment of the invention discloses a method for constructing a three-dimensional map, which comprises the following steps: output data of a laser scanner is obtained, and a two-dimensional mapof an indoor environment is constructed; the mobile robot uses the two-dimensional map to carry out autonomous navigation, and obtains the posture and the posture transformation matrix of the mobile robot; at the same time of autonomous navigation of the mobile robot, the kinect sensor is used to acquire two-dimensional images of the indoor environment, the two-dimensional images are converted into three-dimensional point cloud images, and the images are mosaic with neighboring point cloud images to obtain the kinect sensor posture and posture transformation matrix; the optimal posture and theoptimal posture transformation matrix of the Kinect sensor are obtained by Kalman filter. According to the optimal posture and the optimal posture transformation matrix of the Kinect sensor, the image mosaic of adjacent point cloud is completed, and the 3D map of indoor environment is constructed. By adopting the invention, the positioning accuracy of the mobile robot in the indoor navigation process is improved, the mismatch of the image mosaic is avoided, and the chaotic phenomenon of the image matching in the repetition area is overcome.

Owner:SHANTOU UNIV

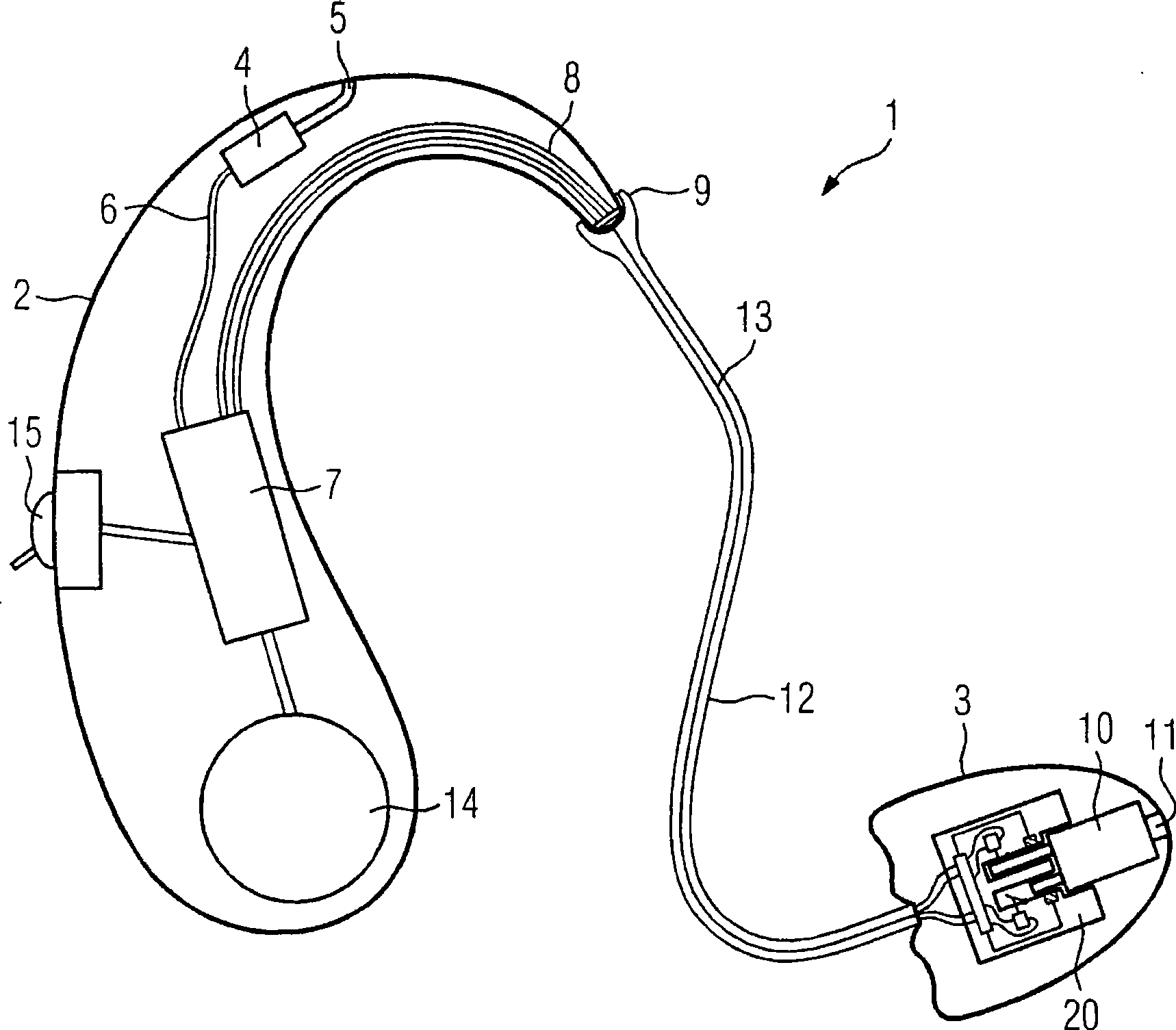

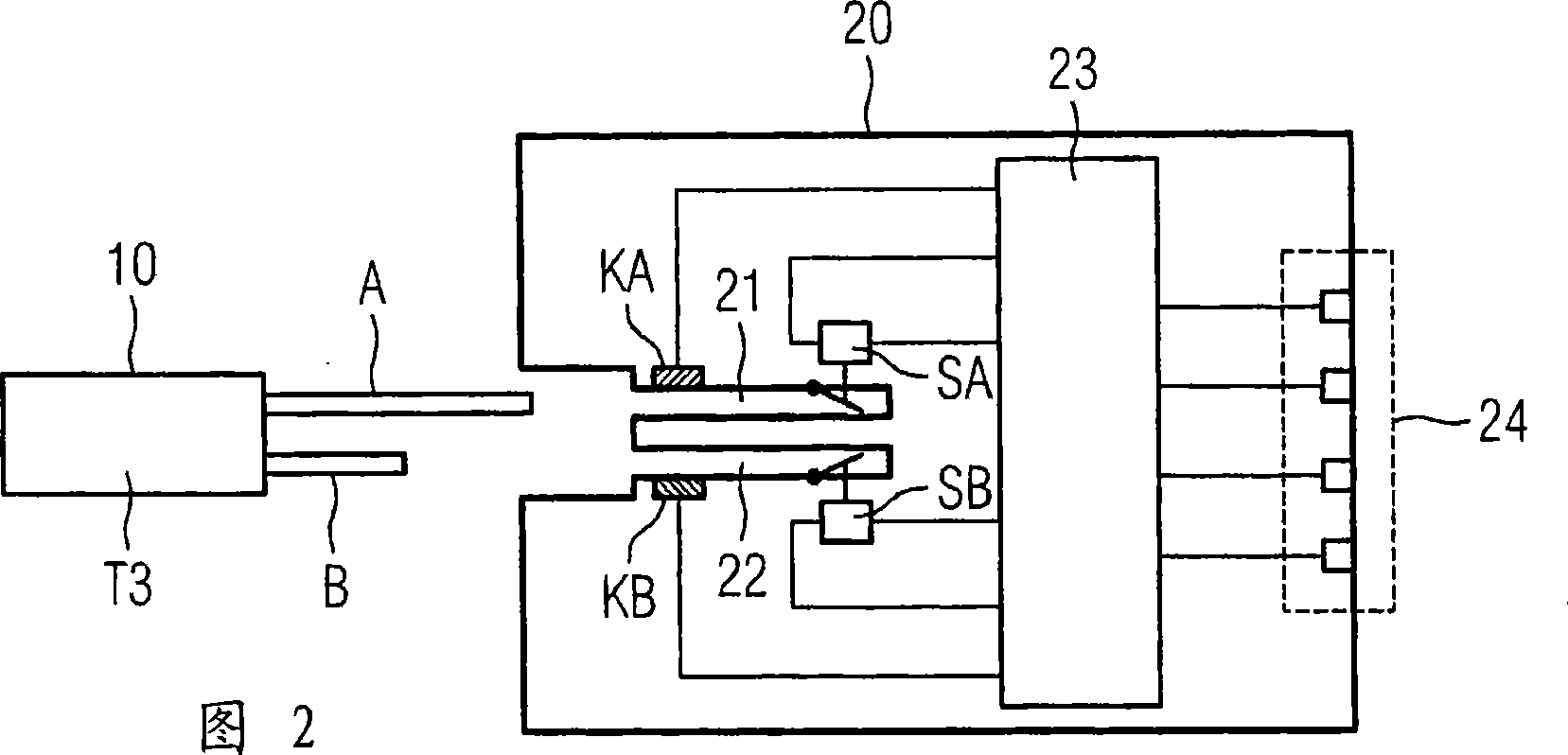

Automatic identification of receiver type in hearing aid devices

In a hearing aid system having at least one hearing aid (1; 31), the incorrect matching between the signal processing unit (7; 37) of the hearing aid (1; 31) and the used receiver (10; 40). So, the hearing aid system automatically recognizing the model of the used receiver and automatic matching of the signal processing in the hearing aid (1; 31) are suggested. Therefore, the incorrect manual matching is avoided.

Owner:SIWANTUO CO LTD

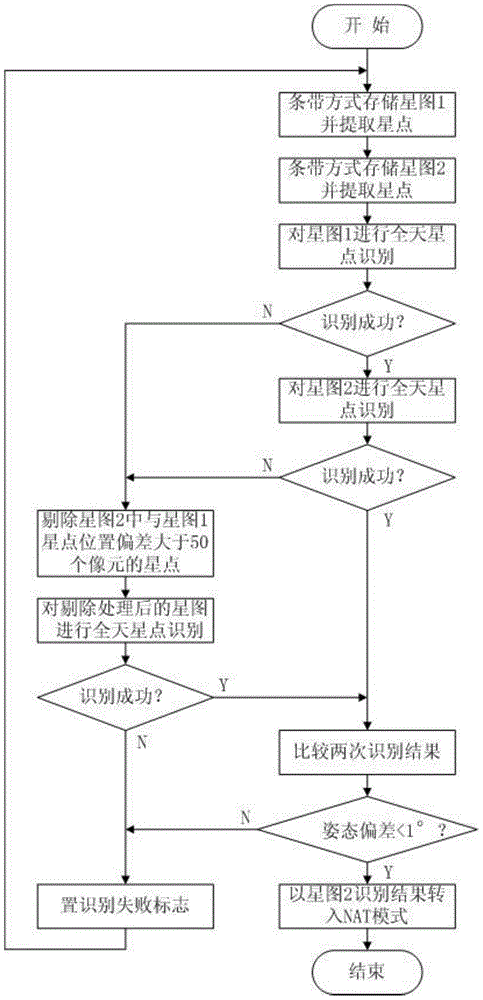

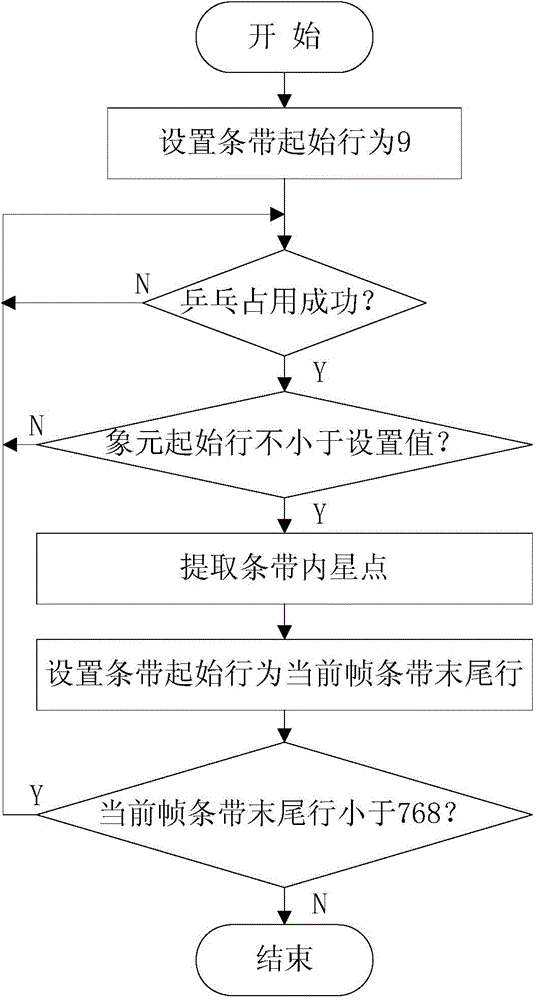

Attitude capture method of star sensor under space particle interference condition

ActiveCN104567865AGet stableAvoid false matchesNavigation by astronomical meansStar sensorSpace environment

The invention discloses an attitude capture method of a star sensor under the space particle interference condition. The method comprises steps as follows: when attitude capture of the star sensor is interfered by space particles, rolling strip type storage is performed on effective pixels read from an image surface of the star sensor, so that complete star map star point information is acquired; matching identification is performed by the aid of the star map star point information, position information of multiple frames of star points is compared when matching fails, the star points with larger deviations are rejected, and then matching identification is performed again; attitude calculation is performed by the aid of matching identification results, multiple frames of attitude capture results are compared and verified, and attitude capture is judged to be successful when deviations between the results meet requirements. According to the method, comparison and screening are performed according to multiple frames of complete star point position information, pseudo star points caused by space particle interference can be accurately distinguished, and the correctness of attitude capture of the star sensor in the space environment can be guaranteed.

Owner:BEIJING INST OF CONTROL ENG

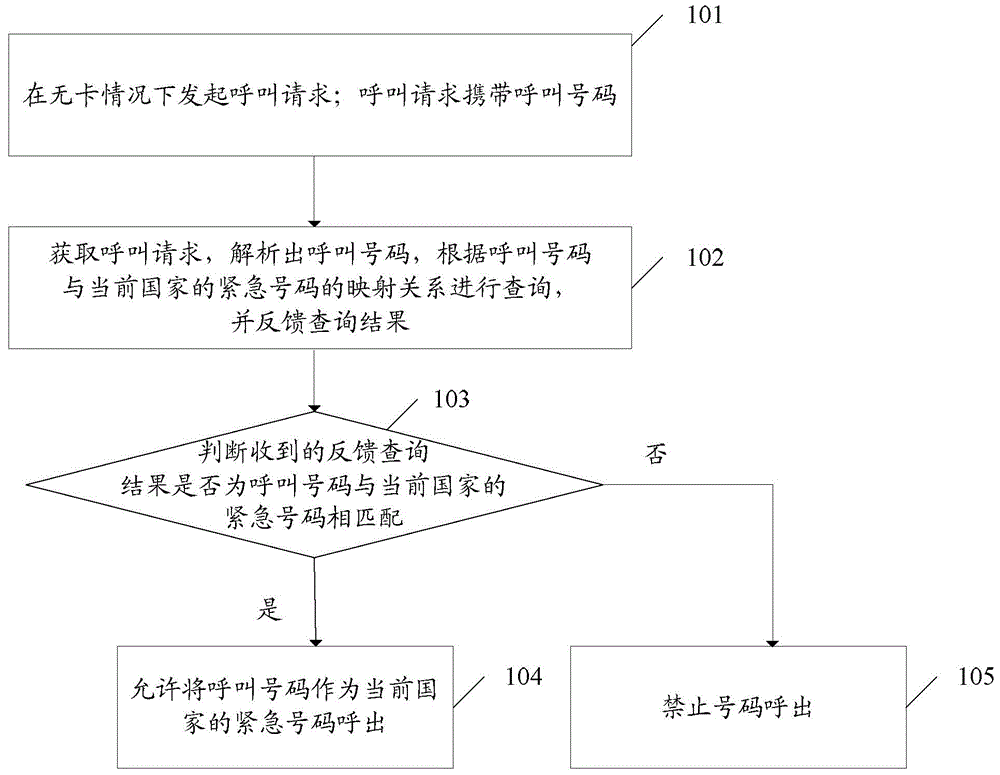

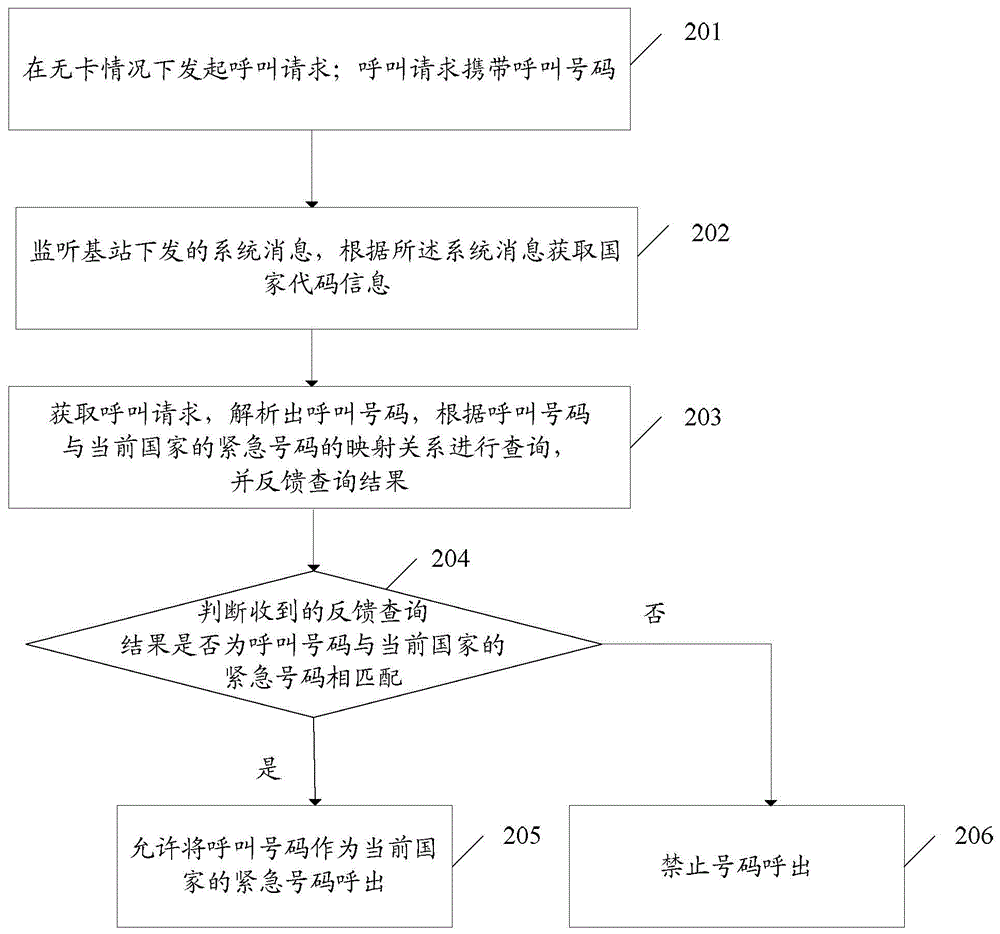

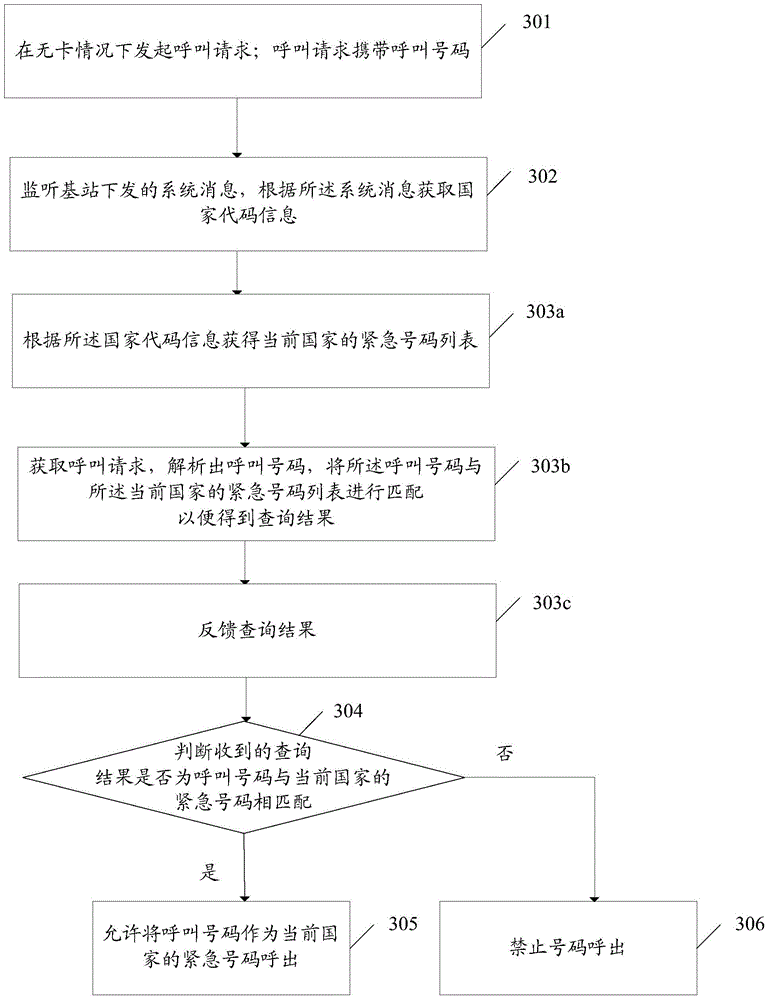

Emergency calling method and electronic equipment

InactiveCN104581668AQuick callExhale fastWireless commuication servicesEmergency/hazardous communication serviceWorkloadComputer science

The invention discloses an emergency calling method and electronic equipment. The method is applied to the electronic equipment and comprises steps as follows: initiating a call request carrying a call number in the absence of a card; acquiring the call request, analyzing the call number, performing inquiry according to the mapping relation between the call number and a current national emergency number, and feeding back an inquiry result; judging whether the received and fed inquiry result is that the call number is matched with the current national emergency number, if yes, allowing the call number to be called as the current national emergency number; otherwise, forbidding calling. With the adoption of the emergency calling method, problems of wrong matching and the heavy maintenance workload caused by adoption of existing emergency calls in the absence of cards are solved at least, numbers can be matched quickly, emergency calls are realized, and the calling success rate is increased.

Owner:LENOVO (BEIJING) CO LTD

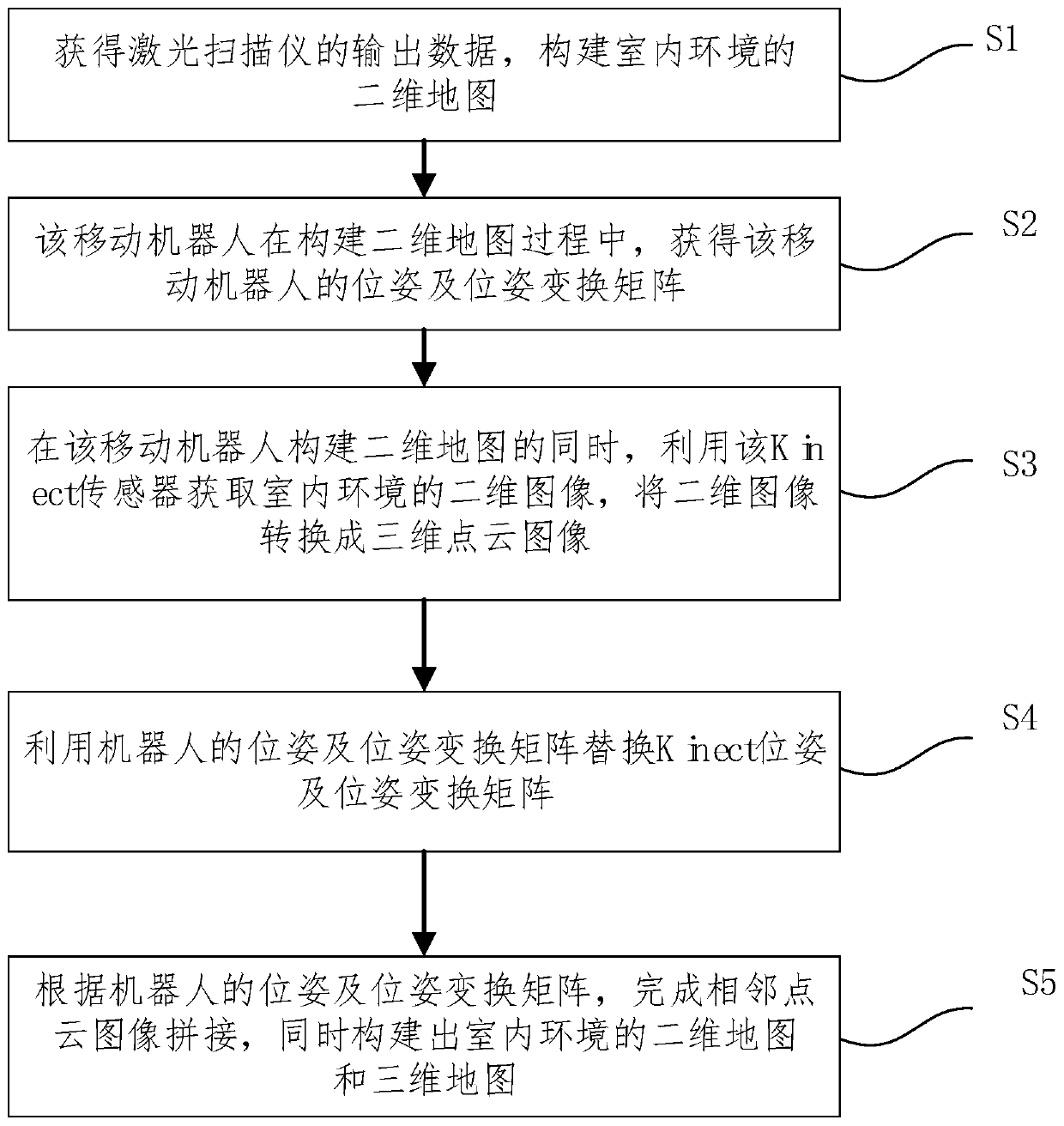

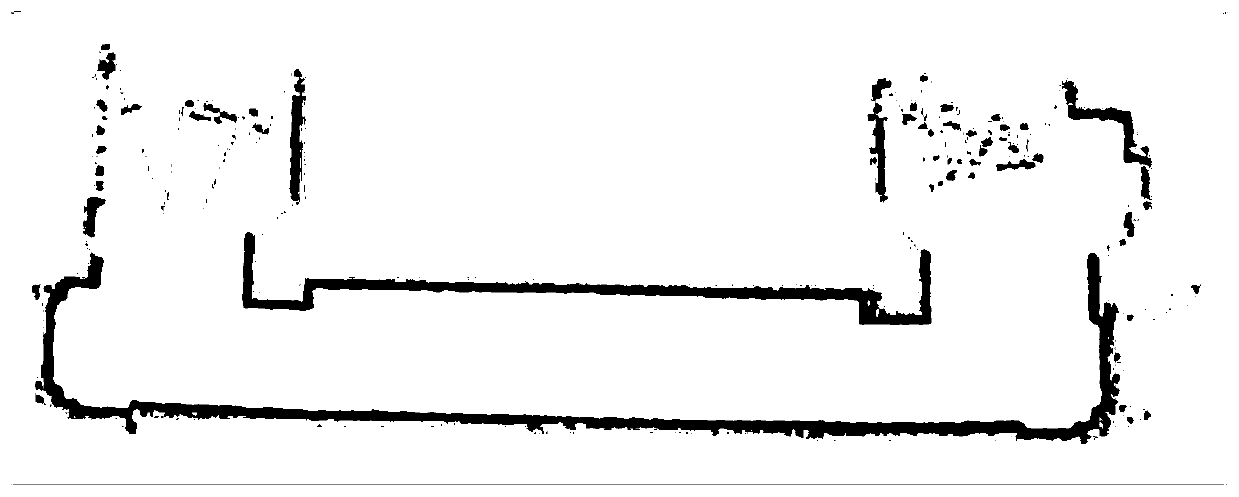

Method for simultaneously constructing two-dimensional map and three-dimensional map

InactiveCN110243375AHigh positioning accuracyLow costNavigational calculation instrumentsElectromagnetic wave reradiationPoint cloudLaser scanning

The embodiment of the invention discloses a method for simultaneously constructing a two-dimensional map and a three-dimensional map, and the method is implemented by a mobile robot provided with a wheel encoder, a laser scanner and a Kinect sensor. The method comprises the following steps of obtaining output data of the laser scanner, and constructing a two-dimensional map of an indoor environment; in the process of constructing the two-dimensional map, obtaining a pose and a pose transformation matrix of the mobile robot by the mobile robot; while the mobile robot constructs the two-dimensional map, acquiring a two-dimensional image of the indoor environment by using the Kinect sensor, and converting the two-dimensional image into a three-dimensional point cloud image; replacing the Kinect pose and pose transformation matrix by using the pose and pose transformation matrix of the robot; and finishing adjacent point cloud image splicing according to the pose and pose transformation matrix of the robot, and simultaneously constructing the two-dimensional map and the three-dimensional map of the indoor environment.

Owner:SHANTOU UNIV

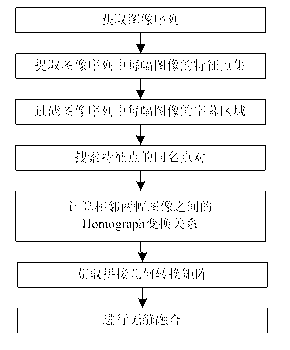

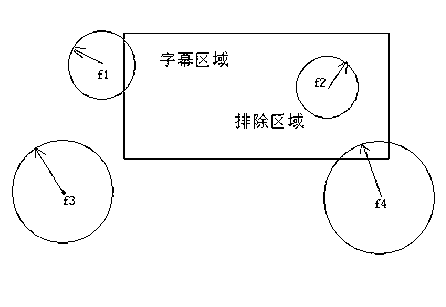

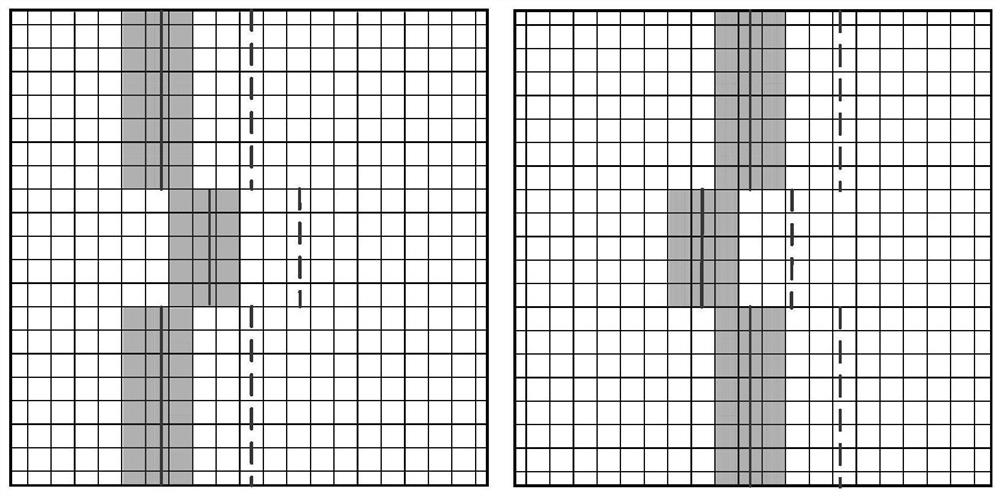

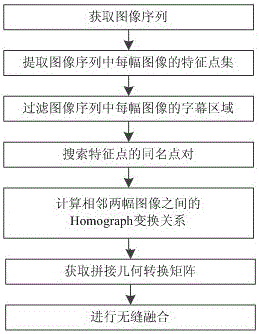

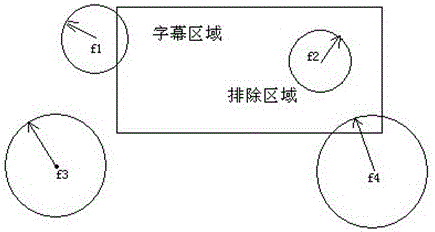

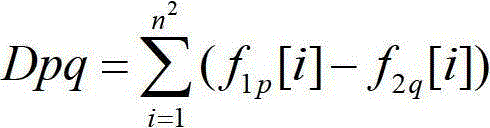

Seamless automatic image splicing method resistant to subtitle interference

InactiveCN103020934AAvoid false matchesGood splicing effectImage enhancementGeometric image transformationPerspective transformationVideo image

The invention provides a seamless automatic image splicing method resistant to subtitle interference. By means of the method, video frames (such as video frames or multiple continuous images shot by a continuously moving or rotating camera) in a varied scene can be continuously spliced to form a complete image. Camera position and pose and scene control point information, proportion and perspective transformation are not required, and rotation of videos (or image sequences) at any angle is not required to be considered, full-automatic color video image seamless splicing is achieved, various high-saliency associated information among the image sequences is fully utilized to perform automatic splicing calculation, the splicing accuracy of adjacent frames can reach to sub pixel, and a parallel technology can be utilized to improve the splicing speed in multiples.

Owner:WUHAN UNIV

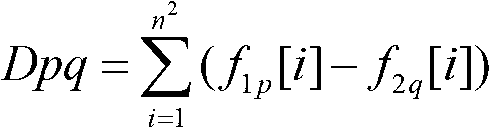

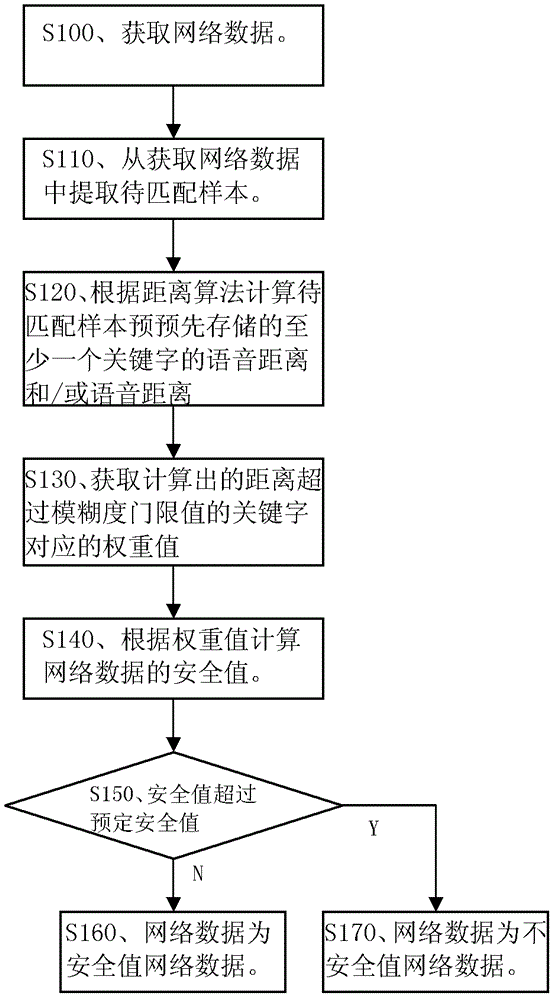

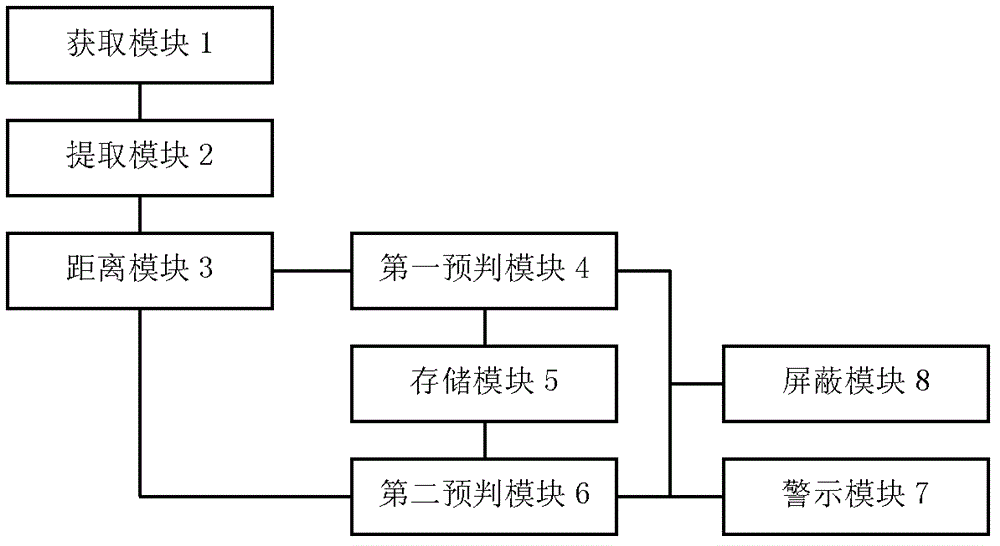

Network data security management method and equipment

The invention relates to a network data security management method and network data security management equipment. The network data security management method comprises the following steps of: acquiring network data; extracting a sample to be matched from the network data; calculating a voice distance and / or a semantic distance between the sample to be matched and at least one pre-stored keyword according to a distance algorithm; acquiring a weight value corresponding to a keyword which is at a distance which exceeds an ambiguity threshold value away from the sample to be matched; calculating a security value of the network data according to the weight value; and determining that the network data are secure network data if the security value does not exceed a preset security value, otherwise determining that the network data are insecure network data. By using the technical scheme, sensitive data can be accurately filtered and early-warned, and a pseudo-matching phenomenon can be avoided, so that the security of the network data is enhanced, and the method and the equipment are practical.

Owner:BEIJING TIANYI DIANLIAN TECH

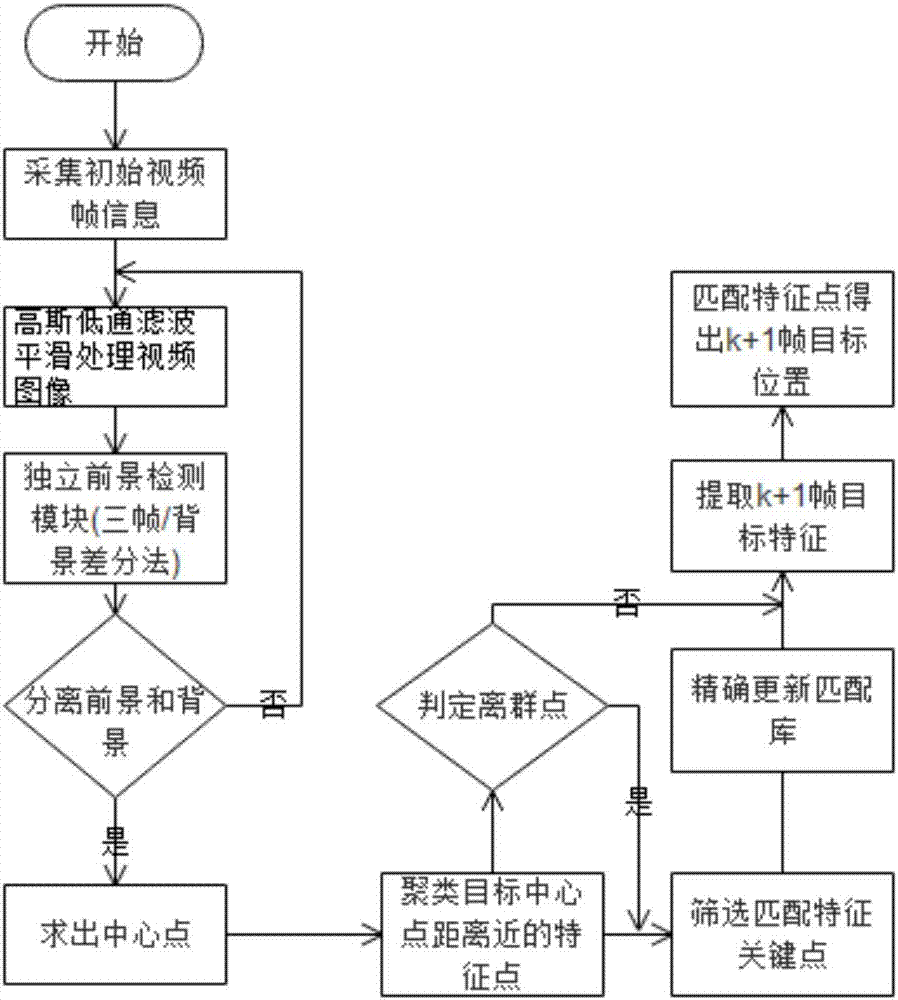

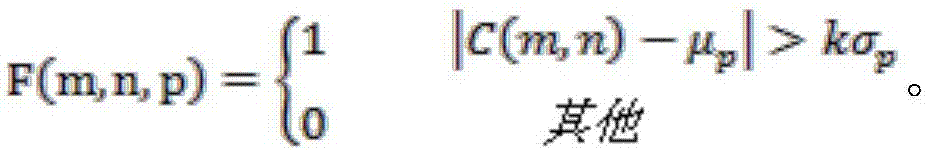

Target tracking method based on multi-feature cluster matching in dynamic environment

InactiveCN107507223AEliminate characterizationAvoid false matchesImage enhancementImage analysisSelf adaptiveFrame difference

The invention discloses a target tracking method based on multi-feature cluster matching in a dynamic environment. According to the tracking method, a three-frame difference method and a background difference method are combined as an adaptive target detection method in a dynamic environment. An independent foreground detection module is designed for a tracking system. A target can be extracted to the maximum, and the noise resistance is strong. Matching tracking is completed by combining the method with a feature clustering method and eliminating mismatched feature points.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

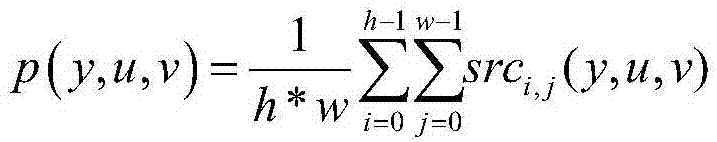

Camera self-calibration method based on two-dimensional mark code

InactiveCN106600649AEasy to identifyAchieve matchingImage analysisPoint cloudComputer graphics (images)

The invention discloses a camera self-calibration method based on a two-dimensional mark code. The method comprises the following steps of setting a two-dimensional target with a mark code; carrying out image acquisition on the two-dimensional target and acquiring a two-dimensional target image group possessing the mark code; detecting the mark code in the two-dimensional target image group and matching to a two-dimensional target image; determining a two-dimensional target base image and calculating an inner parameter matrix and an outer parameter matrix of an image acquisition apparatus; optimizing the inner parameter matrix and the outer parameter matrix of the image acquisition apparatus; and adding the image acquisition apparatus and calculating inner and outer parameters and three-dimensional point cloud of the image acquisition apparatus. In the invention, through setting the two-dimensional target possessing the mark code, the image acquisition apparatus is calibrated and technical problems that manufacturing of a three-dimensional target is difficult, an accuracy requirement is high and a self-calibration result precision is poor in a traditional calibration technology are solved.

Owner:XIAN SUANIER ELECTRONICS TECH

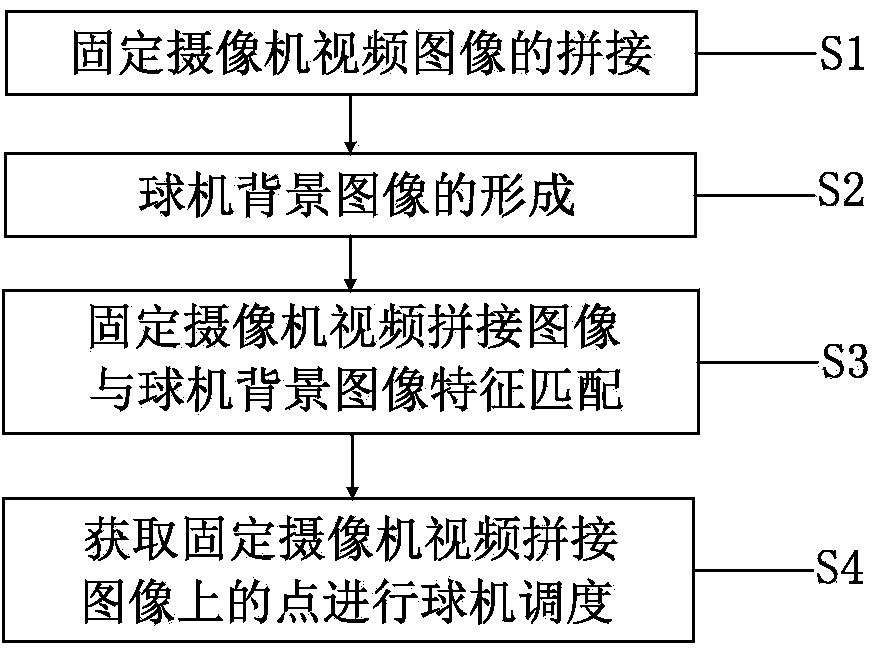

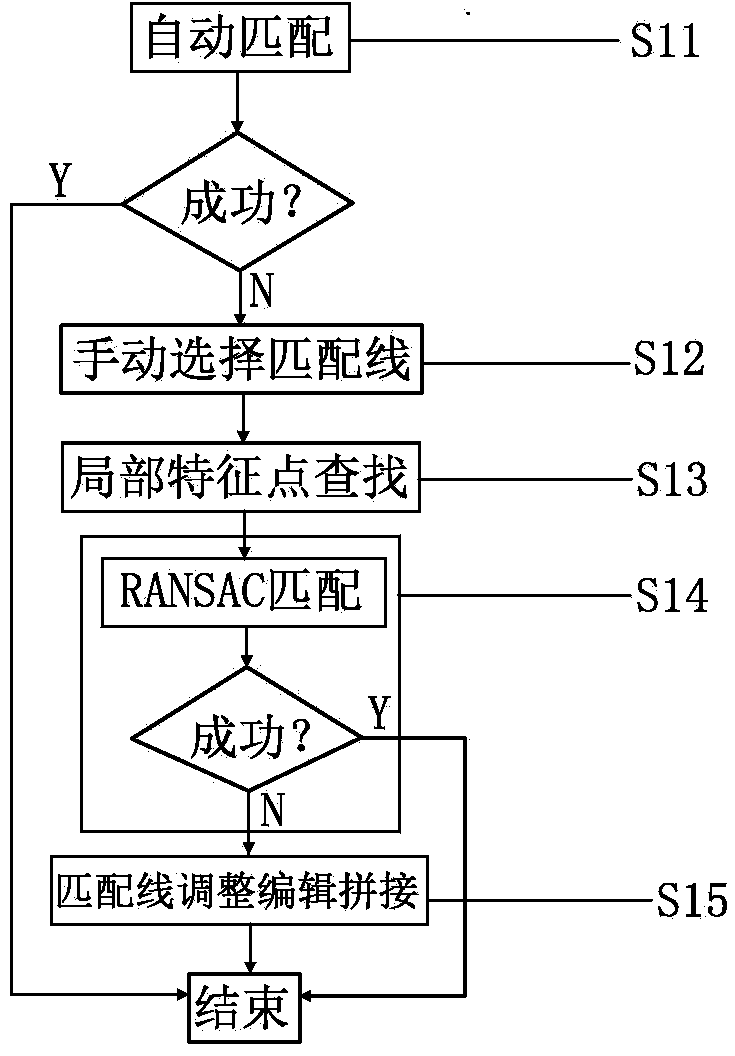

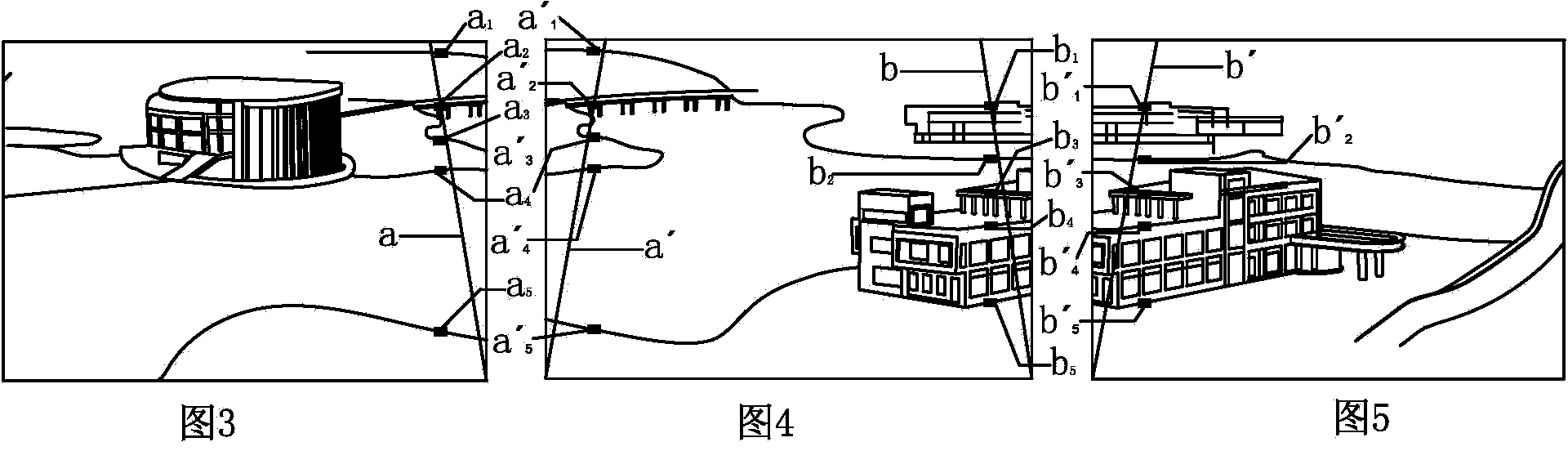

Panoramic monitoring and PTZ camera linkage method based on video feature matching

InactiveCN104301674AAvoid false matchesAvoid unmatchedImage analysisClosed circuit television systemsBackground imageVideo image

A panoramic monitoring and PTZ camera linkage method based on video feature matching includes the following steps of splicing of fixed camera video images, forming of a PTZ camera background image, feature matching of a fixed camera video spliced image and the PTZ camera background image, and PTZ camera scheduling, wherein in the step of splicing of the fixed camera video images, the video images shot by different fixed cameras from different angles are spliced through the partially constrained feather method to obtain a panoramic video spliced image; in the step of forming of the PTZ camera background image, a PTZ camera scans according to step size to obtain the PTZ camera background image; the feature matching of the fixed camera video spliced image and the PTZ camera background image is carried out in the mode that feature points of the fixed camera video spliced image and the PTZ camera background image are extracted for feature matching, and a mapping relation between the fixed camera video spliced image and the PTZ camera background image is obtained; PTZ camera scheduling is carried out by obtaining a point on the fixed camera video spliced image, namely the PTZ camera is scheduled to the point by obtaining the point on the fixed camera video spliced image to capture detail information of the point.

Owner:BEIJING ZHENGAN RONGHAN TECH

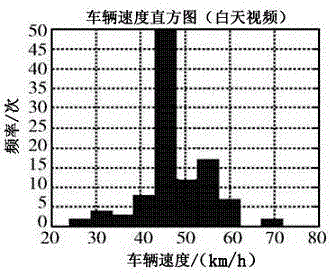

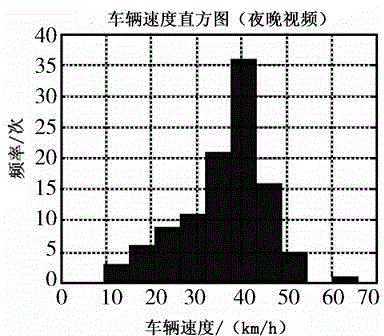

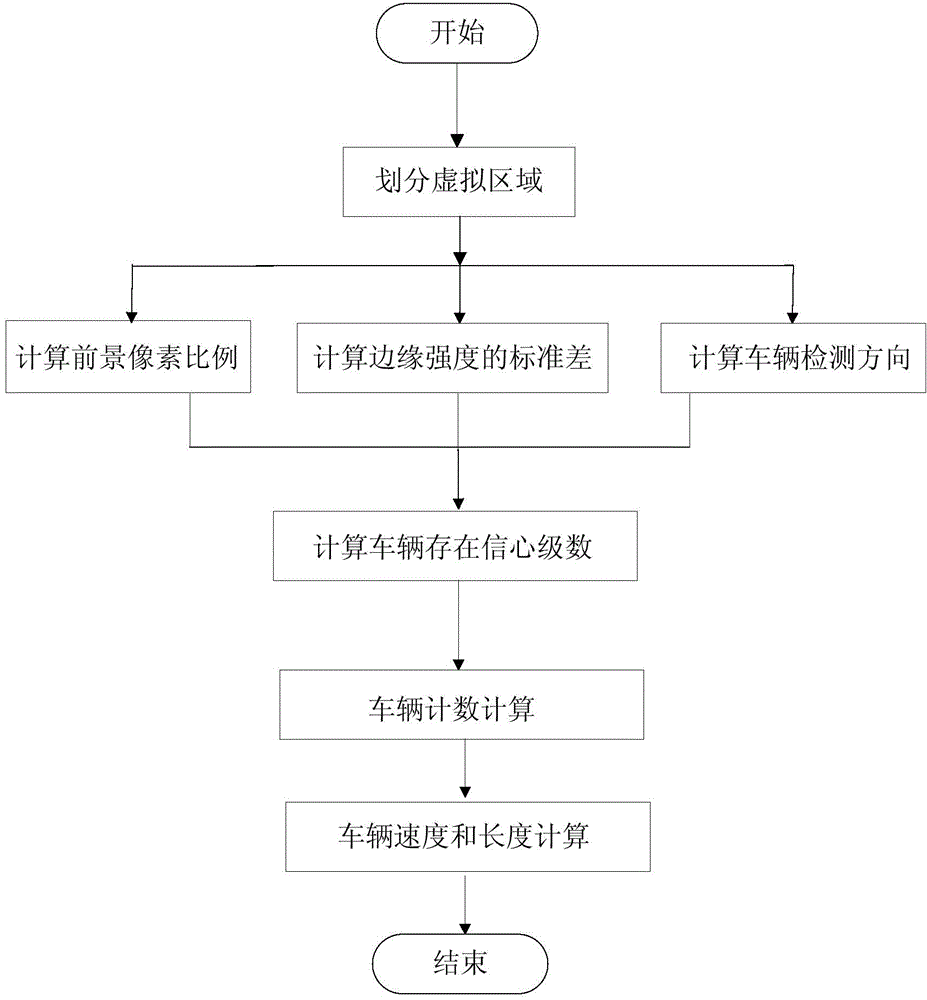

Multi-feature-fusion-based traffic video data collection processing method

InactiveCN104952244AAvoid vehicle mismatch issuesAvoid false matchesDetection of traffic movementSpeed measurementAdverse weather

The invention discloses a multi-feature-fusion-based traffic video data collection processing method. The method comprises the following steps: (1), carrying out virtual region division on a traffic video image; (2), calculating a foreground pixel ratio of a virtual region, determining a standard difference SDe of edge strength, and determining a vehicle detection direction angle VD; (3), calculating a vehicle existence confidence grade number according to the obtained foreground pixel ratio, the standard difference SDe of edge strength, and the vehicle detection direction angle VD based on the image processing at the step (2); and (4), carrying out CL data statistics to determine the number of monitored vehicles. According to the technical scheme, the method has the following advantages: (1), a vehicle is detected by using features like the foreground area, texture change, and pixel motion in a virtual coil comprehensively and the vehicle detection algorithm is free from the influences of the adverse weather and illumination based on effective fusion of three kinds of features; and (2), the vehicle speed is estimated according to the pixel motion vector in the single virtual coil, thereby solving an inherent vehicle wrong matching problem of the dual-coil speed measurement method.

Owner:KUNMING UNIONSCIENCE TECH CO LTD

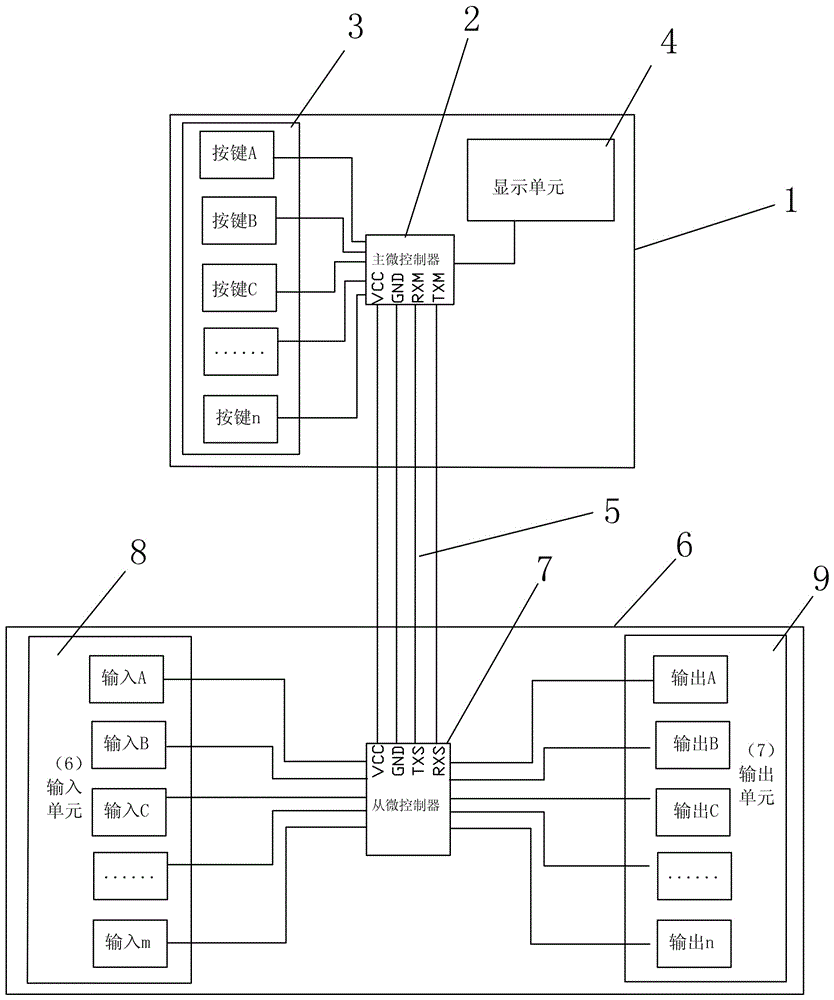

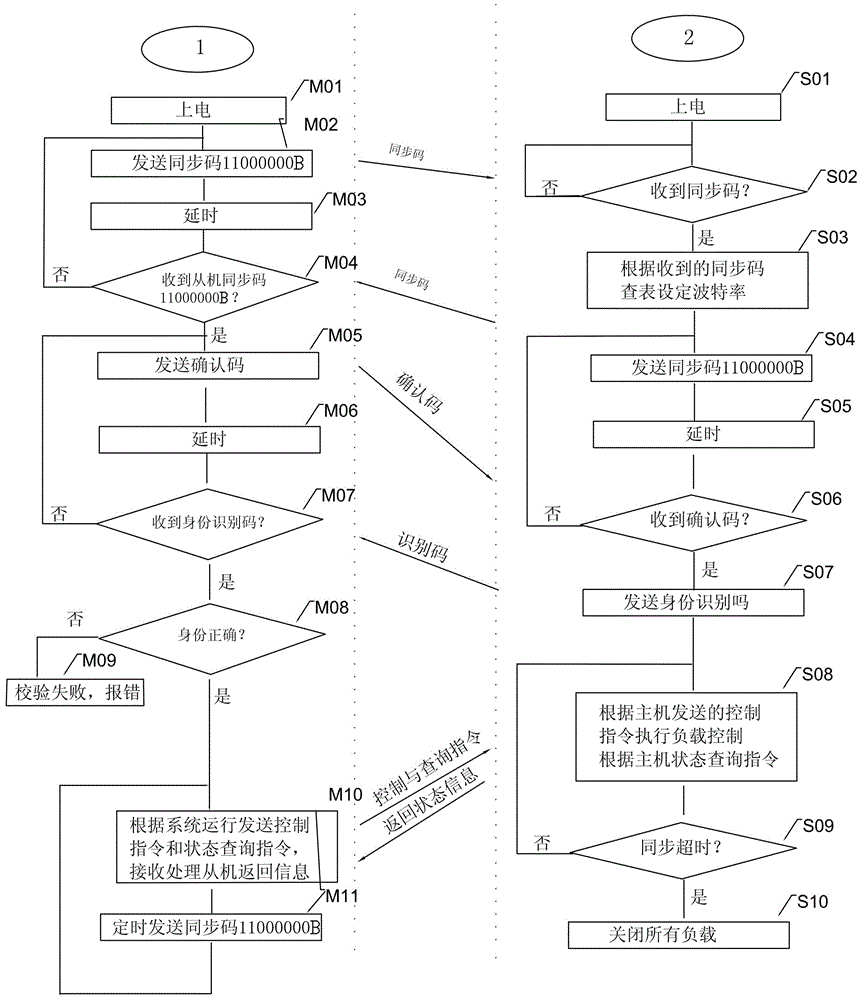

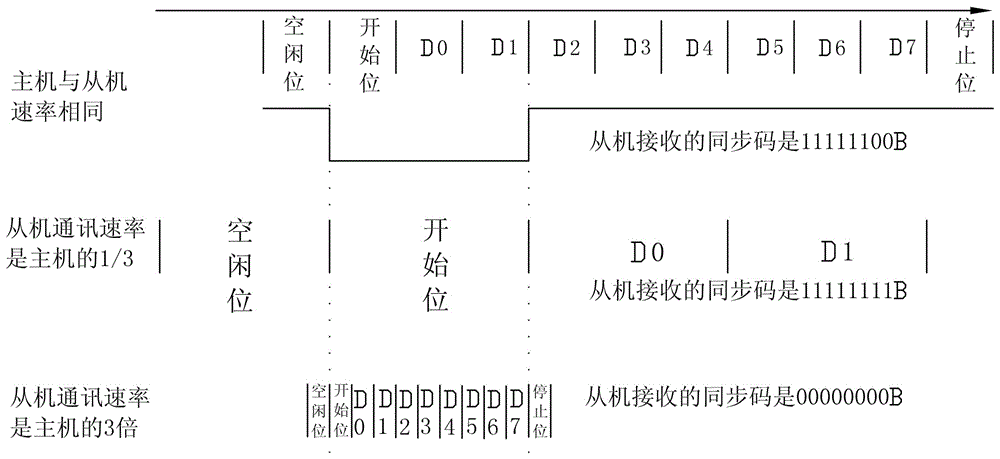

Communication method of circuit board and circuit board

InactiveCN106055497AReduce typesFirmly connectedElectric digital data processingMicrocontrollerComputer architecture

The invention specifically relates to a communication method of a circuit board and the circuit board, and a host computer, a slave computer and microcontrollers are provided. The host computer and the slave computer communicate with each other via a connecting line, the microcontrollers respectively communicate with the host computer and the slave computer via serial communication ports. The method includes the steps of powering up the host computer and the slave computer, sending a synchronous code from the host computer to the slave computer, the searching the corresponding rate parameters from the slave computer's storage rate parameter list according to the synchronous code received, and adjusting to the corresponding execution value and storing the execution value in the memory of the slave computer, executing the execution value after adjustment and sending the synchronous code to the host computer by the slave computer, and receiving and storing the synchronous code send by the slave computer and realizing the communication between the host computer and the slave computer by the host computer. The invention has the advantages that: 1. simplifying the communication by connecting the host computer, the slave computer and the microcontrollers and reducing the fault caused by connection; 2. realizing a unified connection interface which is compatible with different product interfaces, reducing computer types, giving convenience for maintenance, and lowering the cost.

Owner:GUANGDONG YINGKE ELECTRONICS

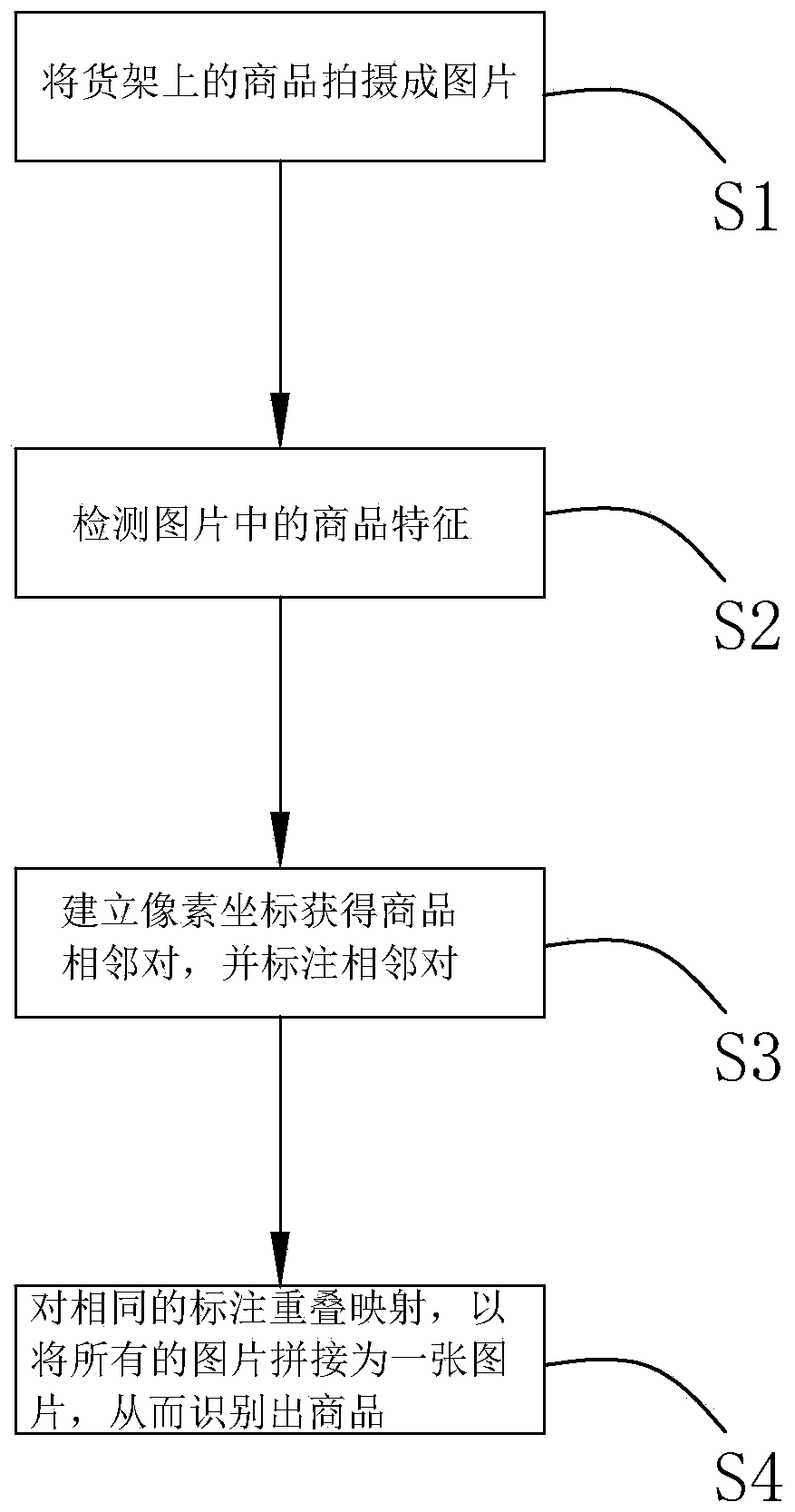

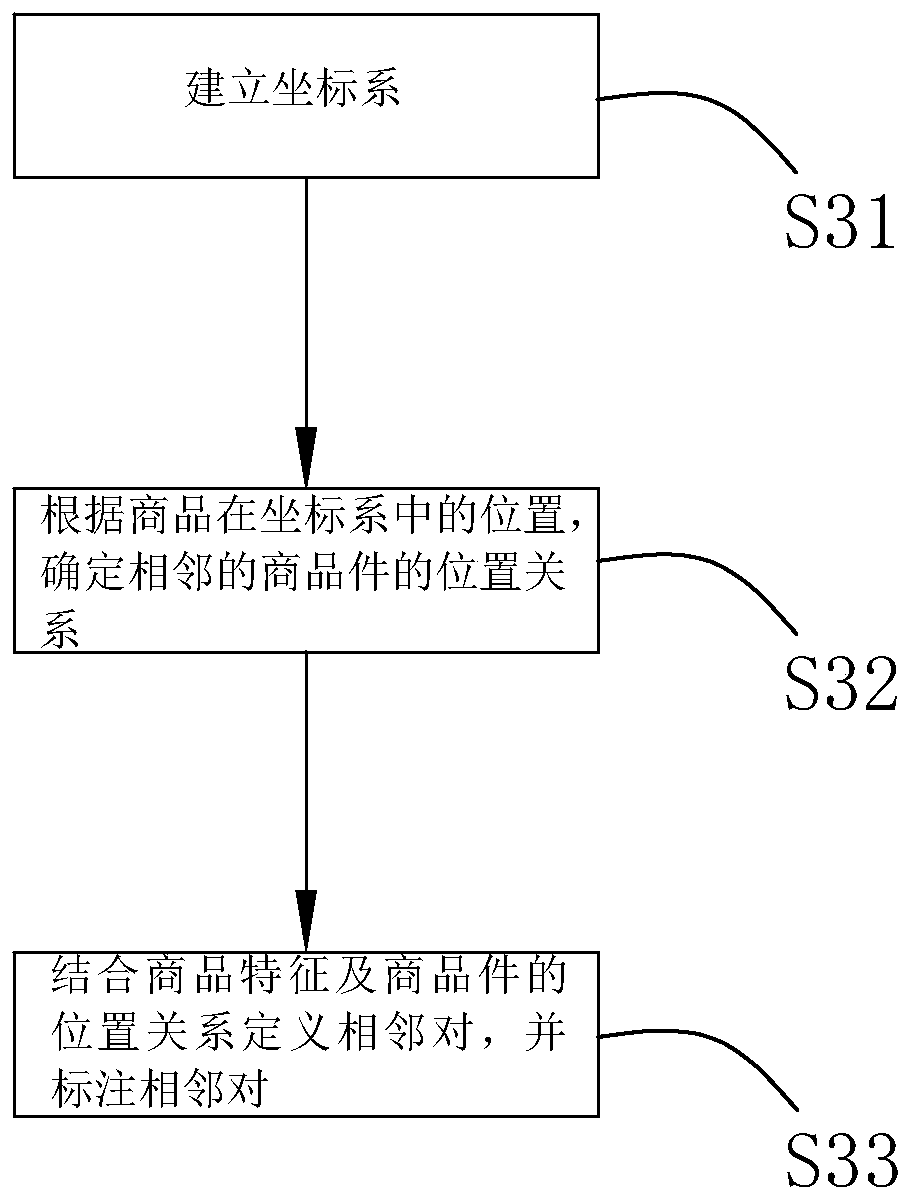

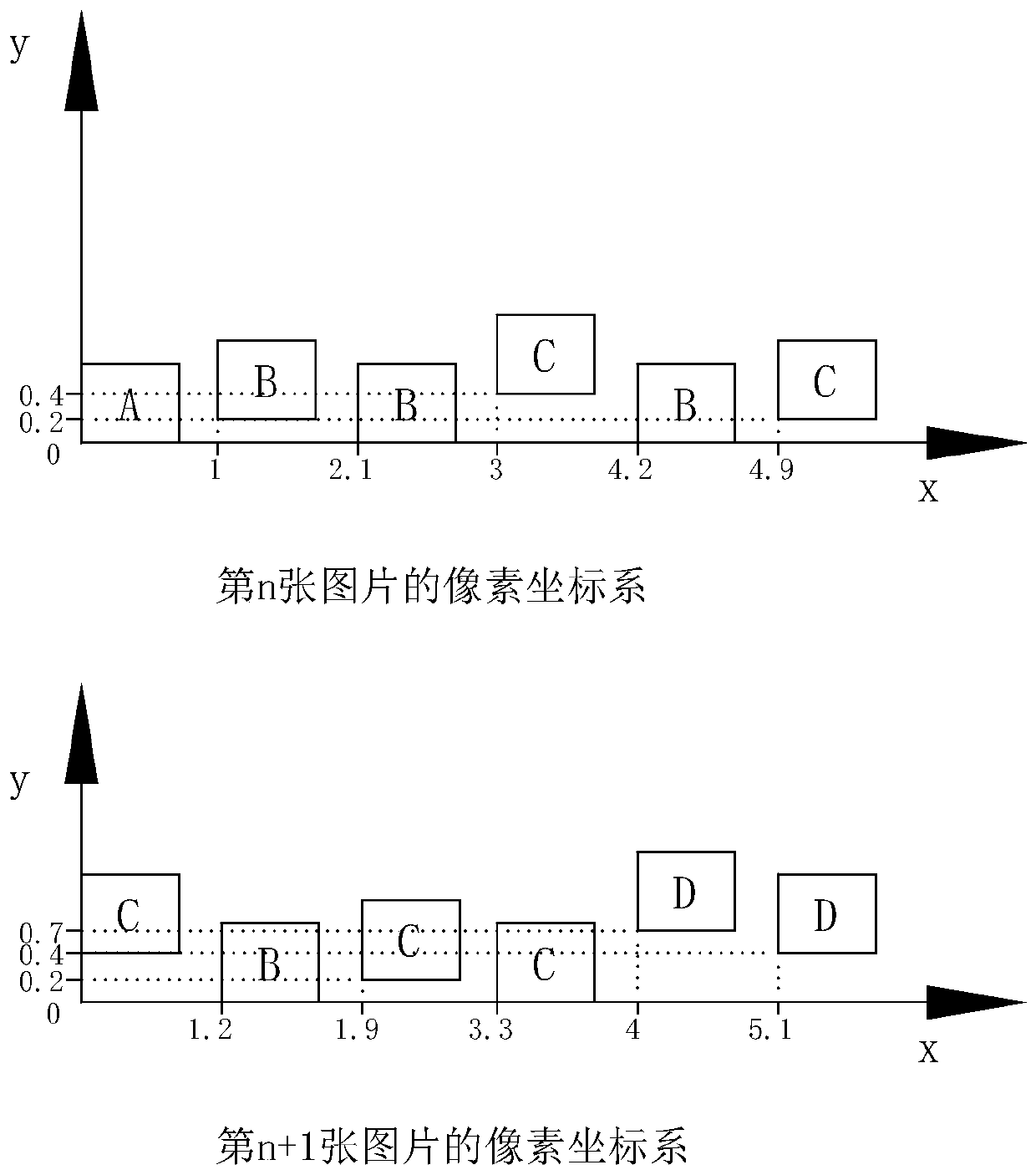

Goods shelf commodity identification method, computer readable medium and identification system

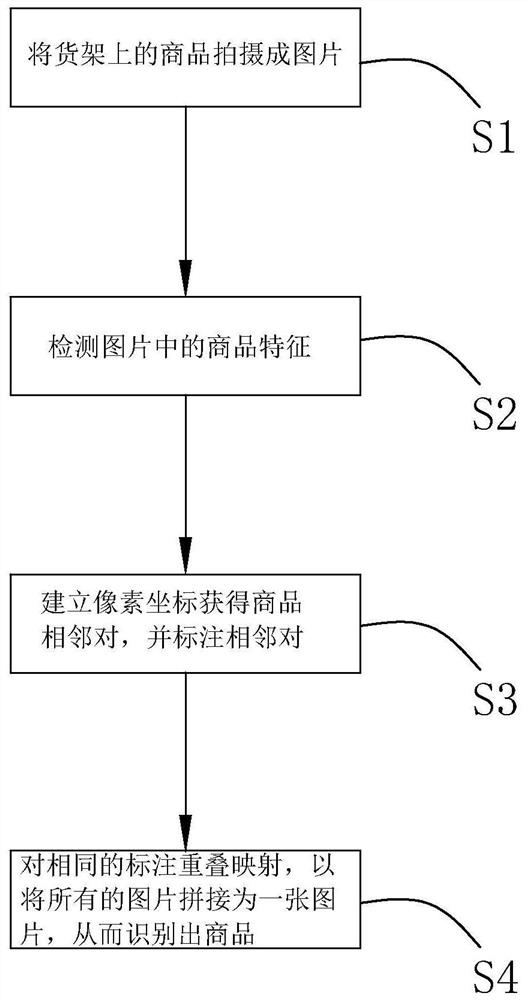

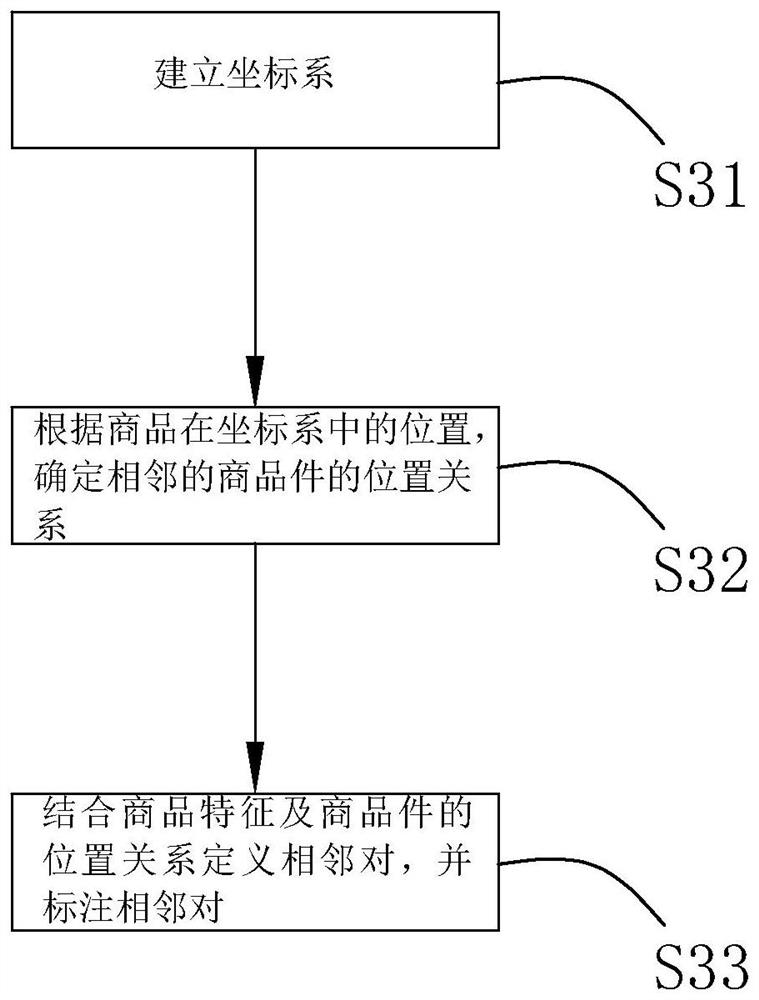

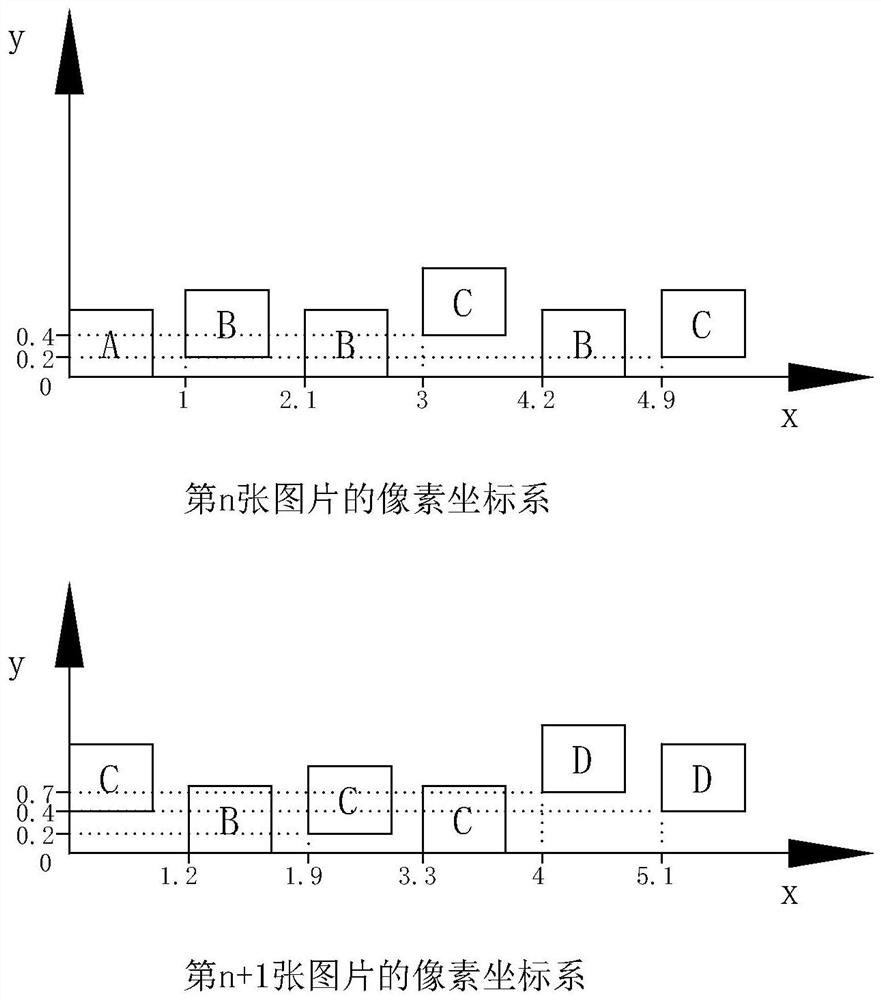

ActiveCN109934093AExpand the receptive fieldAvoid false matchesGeometric image transformationCharacter and pattern recognitionIdentification systemComputer science

The invention relates to a method for identifying goods on a goods shelf, which comprises the following steps of: S1, shooting the goods on the goods shelf into at least two pictures; S2, detecting commodity characteristics in the picture; S3, establishing a coordinate system, obtaining commodity adjacent pairs, and labeling the adjacent pairs; And S4, carrying out overlapping mapping on the sameannotations in the two adjacent pictures so as to splice all the pictures into one picture, thereby identifying the commodity. The invention also provides a computer readable medium. The invention also provides an identification system.

Owner:创新奇智(南京)科技有限公司

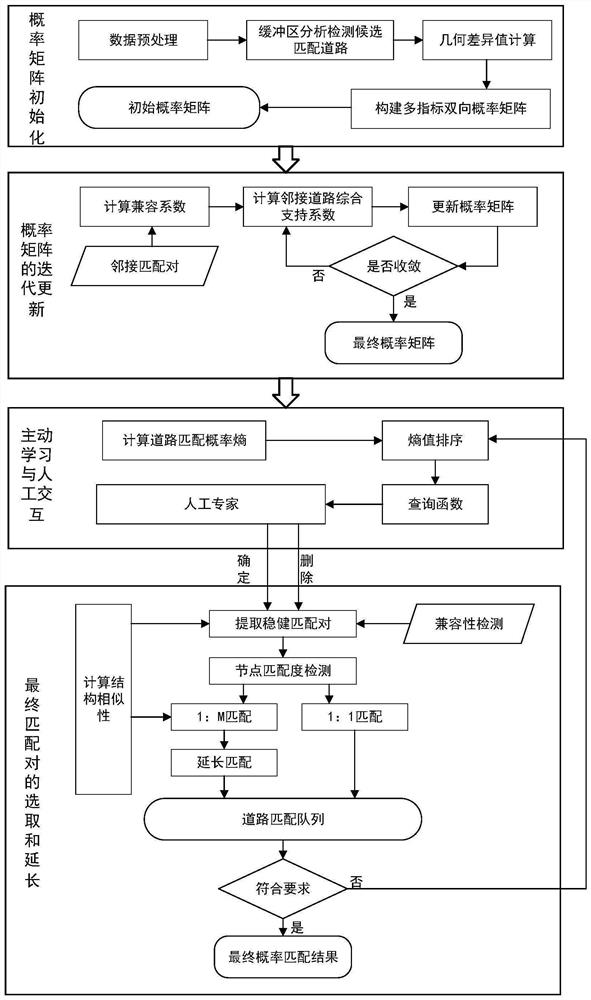

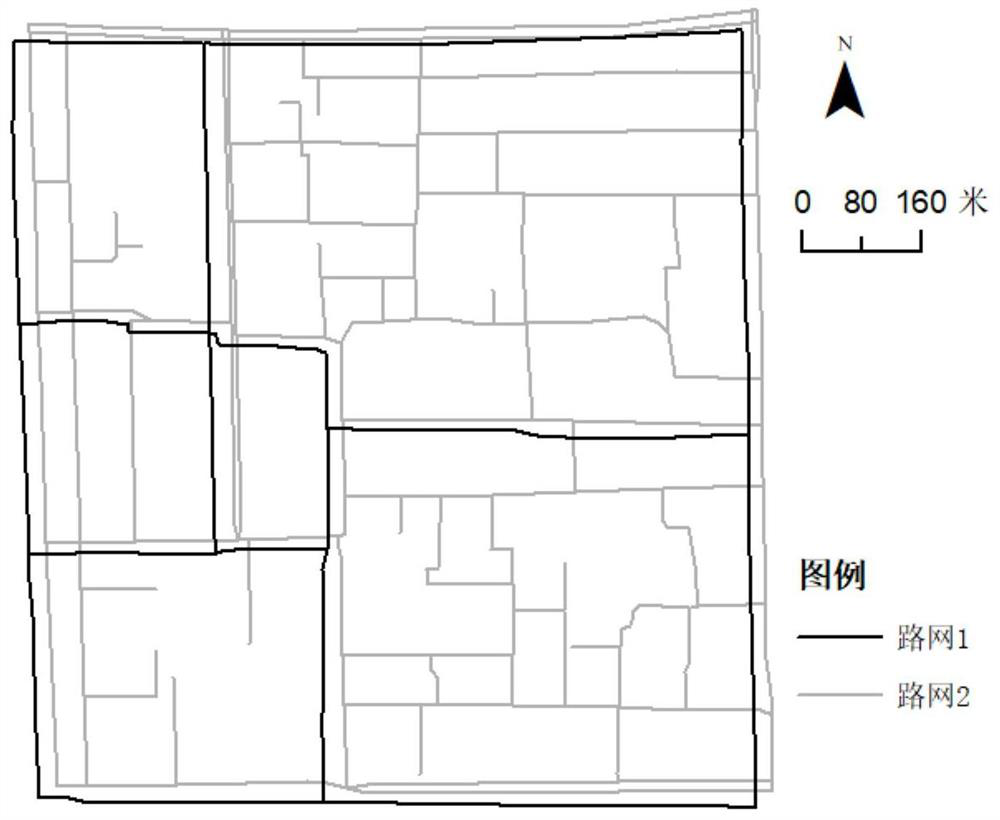

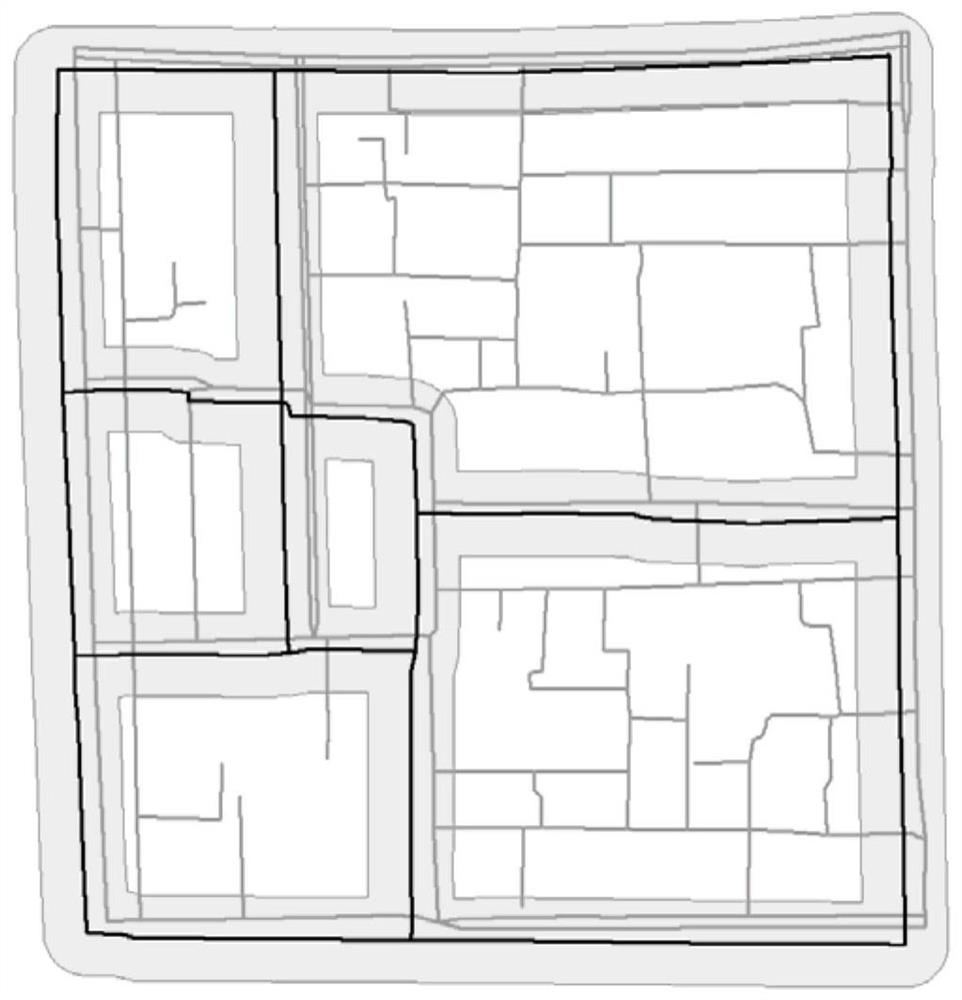

Road network matching method combining human interaction and active learning

PendingCN113704377AHigh precisionReduce matching errorCharacter and pattern recognitionGeographical information databasesEngineeringProactive learning

The invention provides a road network matching method combining artificial interaction and active learning. The method comprises the following steps: carrying out data preprocessing on original road network data to obtain road network information; screening out candidate matching roads through buffer area analysis, and constructing an initial matching probability matrix according to the geometric difference value between the two roads; updating the initial matching probability matrix to enable the road matching to be globally optimal; calculating an entropy value of a road matching probability through a query function, selecting a road which is not marked with a matching object and has the maximum entropy value, and handing over the road to a worker for processing, and constructing a matching constraint set; and finally, based on a matching constraint set of human interaction, optimizing a probability relaxation matching result, and improving the final road matching precision. According to the method, the precision of road network matching can be obviously improved through an active learning method, the problem of wrong matching caused by too high road structure similarity in complex road network matching by using a probabilistic relaxation algorithm is solved, a robust matching pair can better conform to the actual situation, and matching is more accurate.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

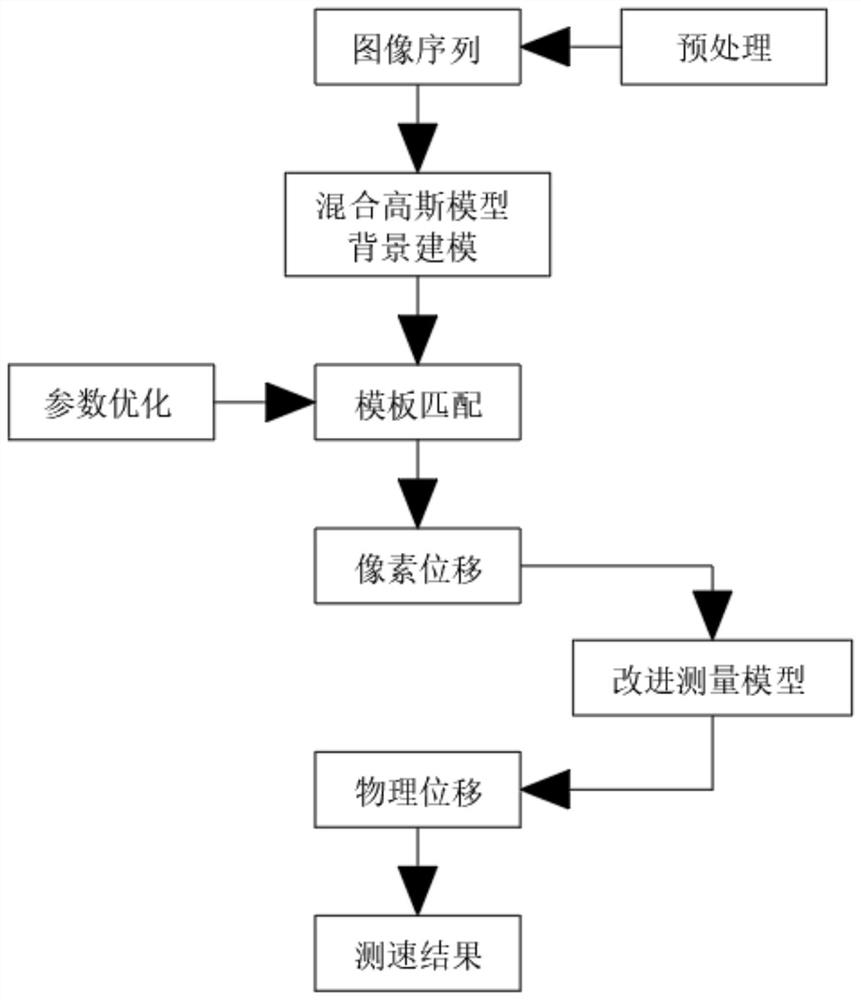

Speed measurement method based on monocular vision system

PendingCN114580559AImprove robustnessFast and precise target recognition and positioningImage enhancementImage analysisMachine visionMedicine

The invention discloses a speed measurement method based on a monocular vision system, and belongs to the technical field of machine vision, and the speed measurement method specifically comprises the following steps: (1) carrying out background modeling by using a Gaussian mixture model; (2) acquiring high-precision pixel displacement of the target by using a parameter-optimized template matching method; (3) accurately acquiring a pixel size corresponding to the target to be measured by using an improved two-dimensional measurement model method; (4) calculating the actual speed according to the proportional relation; according to the method, the Gaussian mixture model is fused based on template matching, a foreground extraction effect which is more stable than that of traditional background difference can be obtained by automatically updating a background model for a complex background and the Gaussian mixture model, and then parameter setting of template matching is optimized, so that the matching success rate is further improved; and finally, the pixel size corresponding to the target is accurately obtained by using an improved two-dimensional measurement model method, the actual speed is converted through the proportional relation between the physical size of the target and the pixel size, and the visual speed measurement precision and robustness can be improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Digital map position information communication method, program for executing the same, program product therefor, system therefor, and apparatus therefor

ActiveCN1830010AAccurate transmissionAvoid false matchesInstruments for road network navigationData processing applicationsError locationComputer science

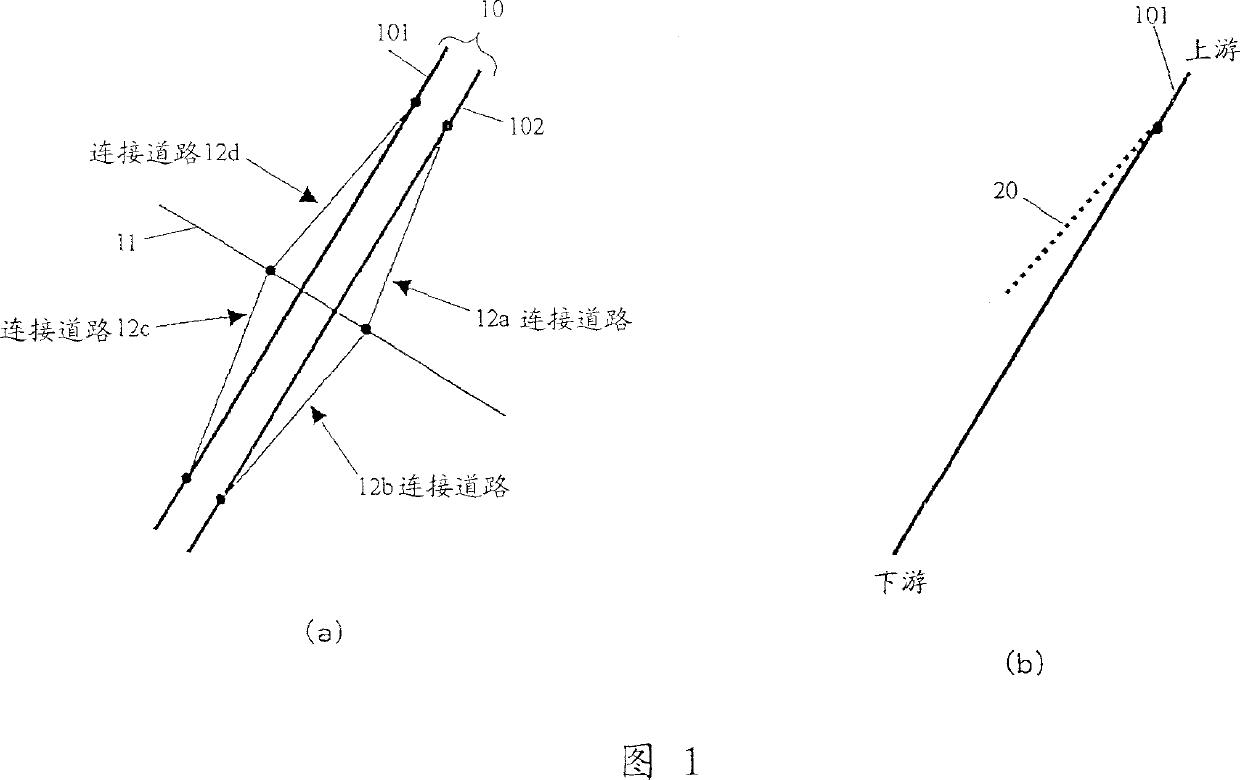

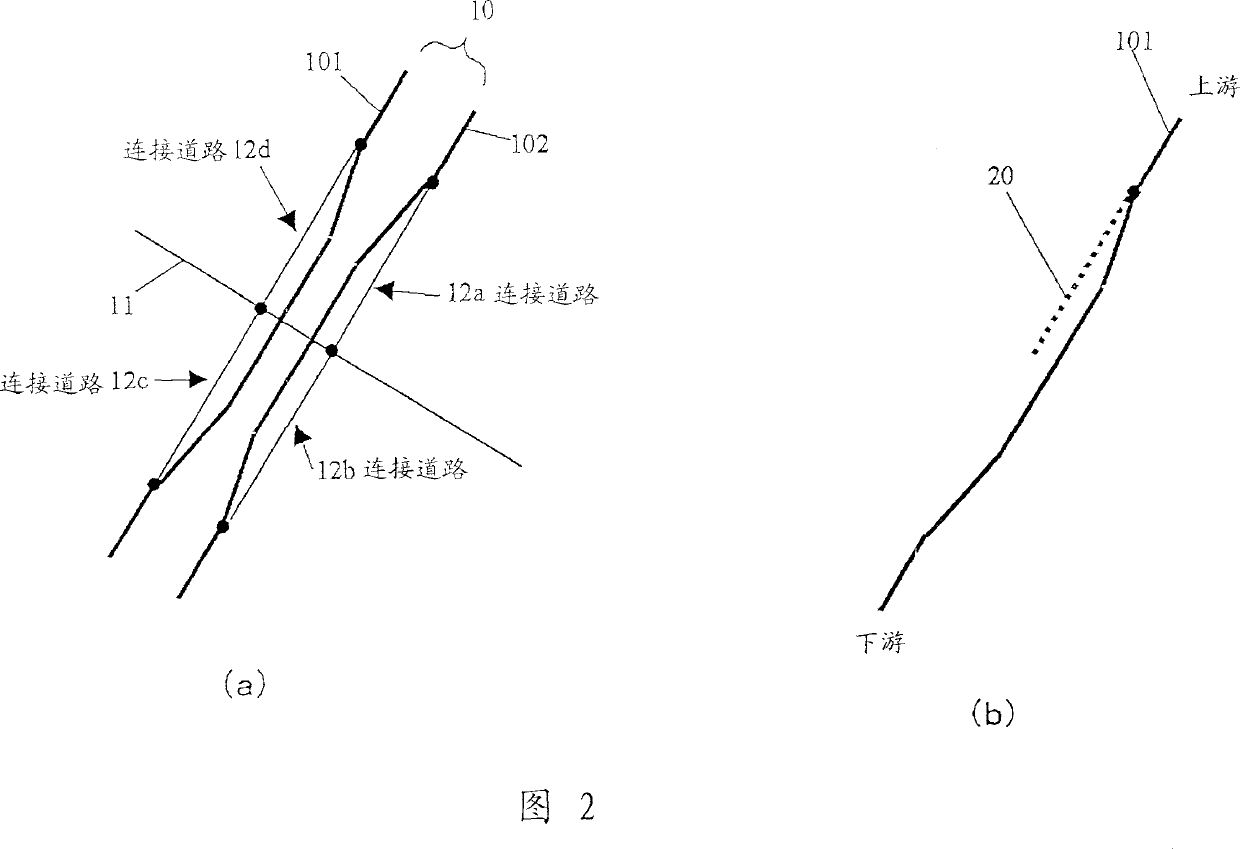

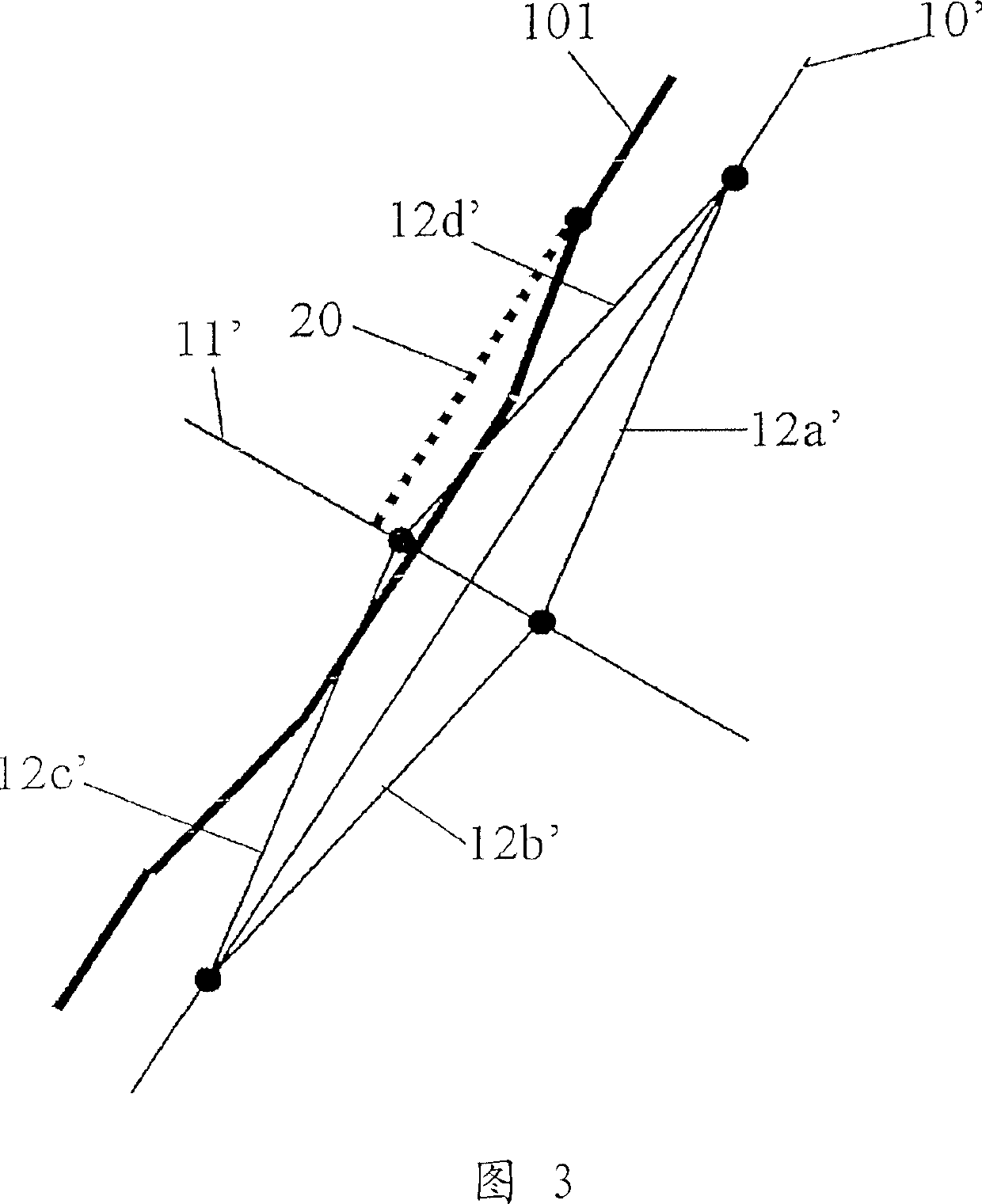

A transmission side transmits the road shape data of an object road 101 to be transmitted, and the branch shape data of a branch 20 intersecting with or branching from the object road 101. A reception side specifies the object road 101 on its own digital map with reference to the branch 20. In this method, the information indicating the shape of a branch or an intersection, which is liable to be erroneously identified, is transmitted as branch shape data to the reception side, so that the reception side can avoid the erroneous location identification. The branch shape 20 makes it possible to discriminate the object road 101 and a parallel road and to discriminate a discrepancy in the longitudinal direction of the object road 101, so that the erroneous location identification to the parallel road or the erroneous location identification in the longitudinal direction of the object road 101 can also be prevented.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

An automatic registration method of aerial and ground lidar data based on building contour constraints

InactiveCN103020966BHigh precisionImprove reliabilityImage analysisWave based measurement systemsAviationCloud data

Disclosed is an automatic registration method of aviation and ground LiDAR data based on building contour constraint. The method includes firstly extracting building contours or aviation contours and ground contours for short from aviation and ground LiDAR data; extracting building angular points or aviation angular points and ground angular points for short from the aviation contours and the ground contours; taking the matching degree between the aviation contours and the ground contours as constraint, calculating initial transfer matrixes between the aviation angular points and the ground angular points, and obtaining initial matching angle dot pairs; finally, calculating correction transfer matrixes between the initial matching angle dot pairs by using an iterative closest point (ICP) algorithm, and converting ground dot cloud data to be matched through the initial transfer matrixes and the correction transfer matrixes successively to achieve automatic high-precision registration of the aviation and ground LiDAR data. The method has great advantages in registration reliability and accuracy with contour lines serving as constraint; and simultaneously, based on LiDAR data to be matched and reference LiDAR data, accuracy registration between the aviation and ground LiDAR data can be achieved without other auxiliary data.

Owner:NANJING UNIV

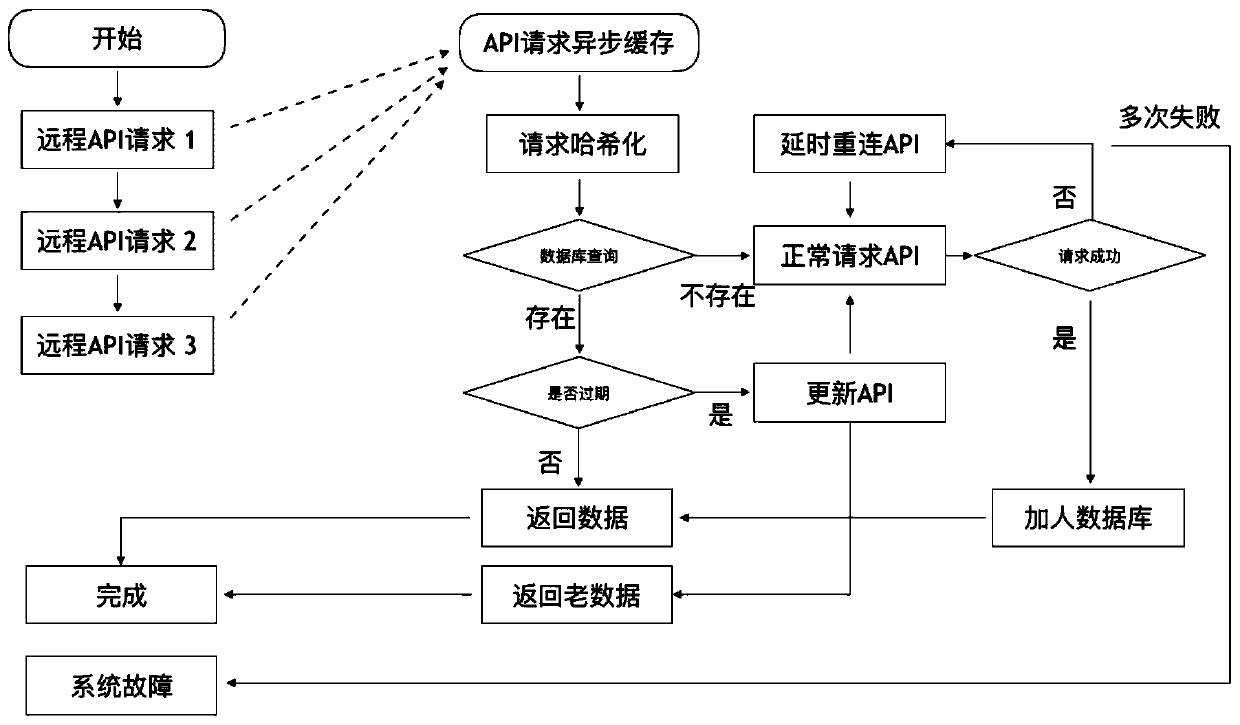

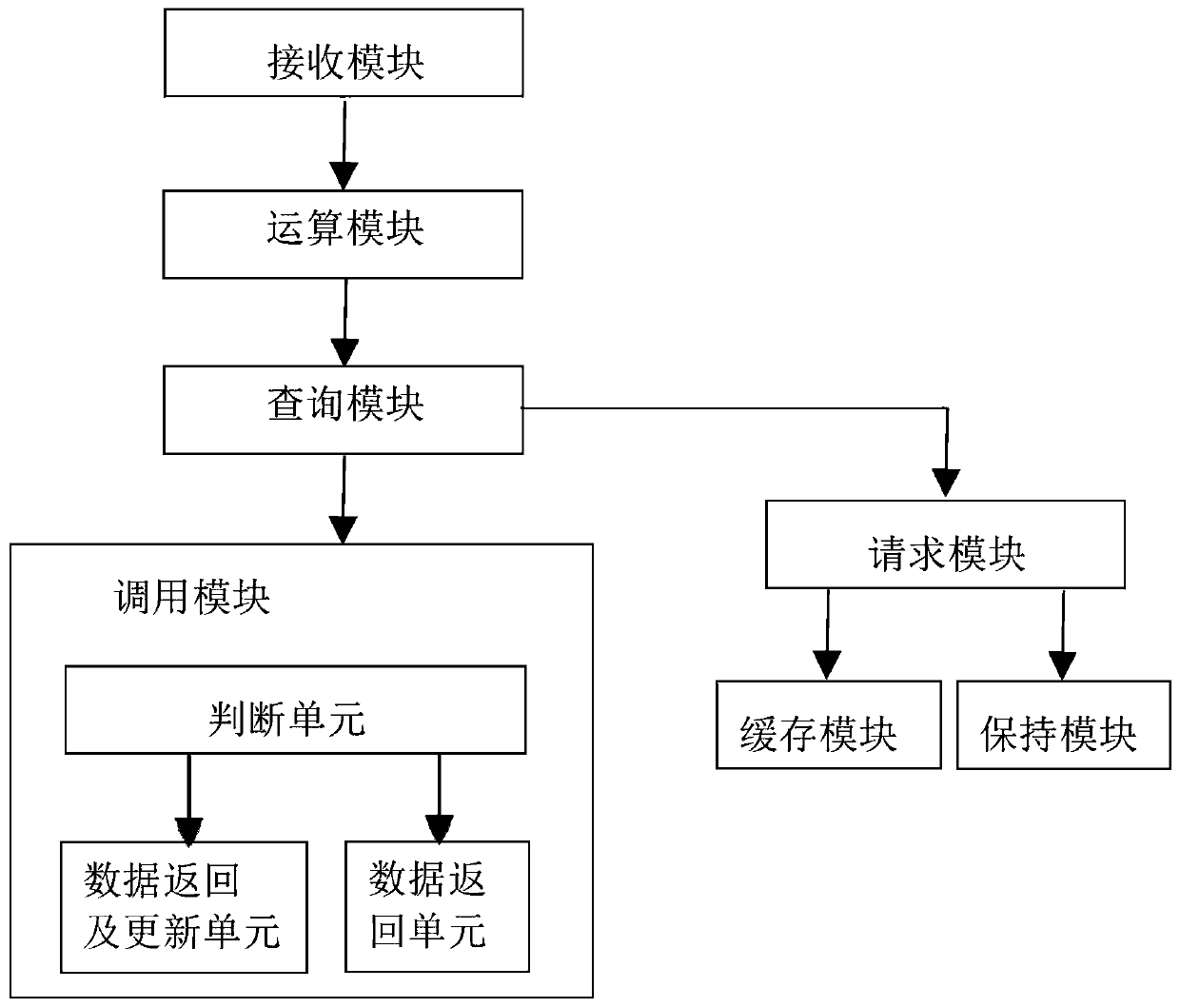

Data caching method and device and server

ActiveCN109783499AAvoid false matchesGuaranteed to be availableSpecial data processing applicationsDatabase indexingOperating systemData cache

The invention discloses a data caching method and device and a server. The method is an asynchronous caching mechanism, when the server calls a plurality of other secondary remote APIs, a link addressand parameters of a request are hashed, so that successful remote API data can be mapped to a local high-speed database. When the server uses the remote API data, the data of the local high-speed database is directly used. When the server uses the API data next time, whether the data expires or not is judged, and the remote API data is asynchronously updated. The response speed of the server canbe increased. The reliability of the whole system is improved, and even if the secondary API has a fault, the device can continue to work by depending on local data.

Owner:成都宝瓜科技有限公司

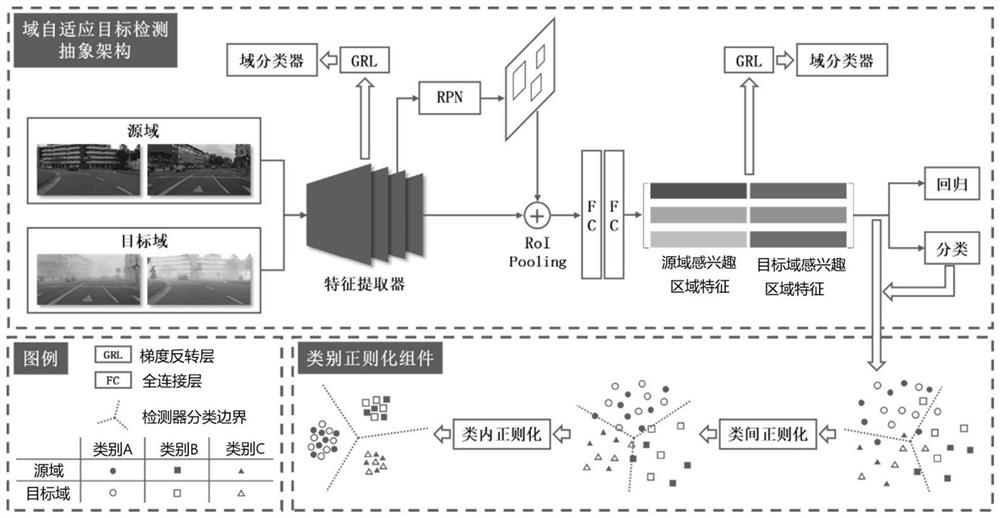

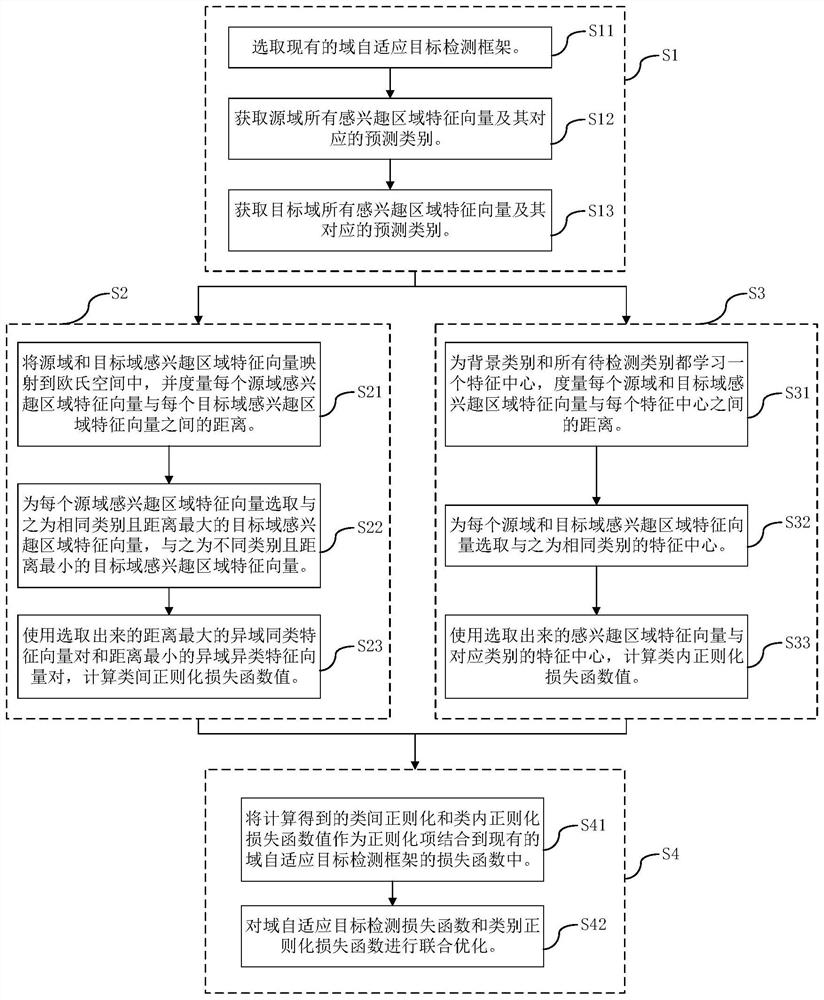

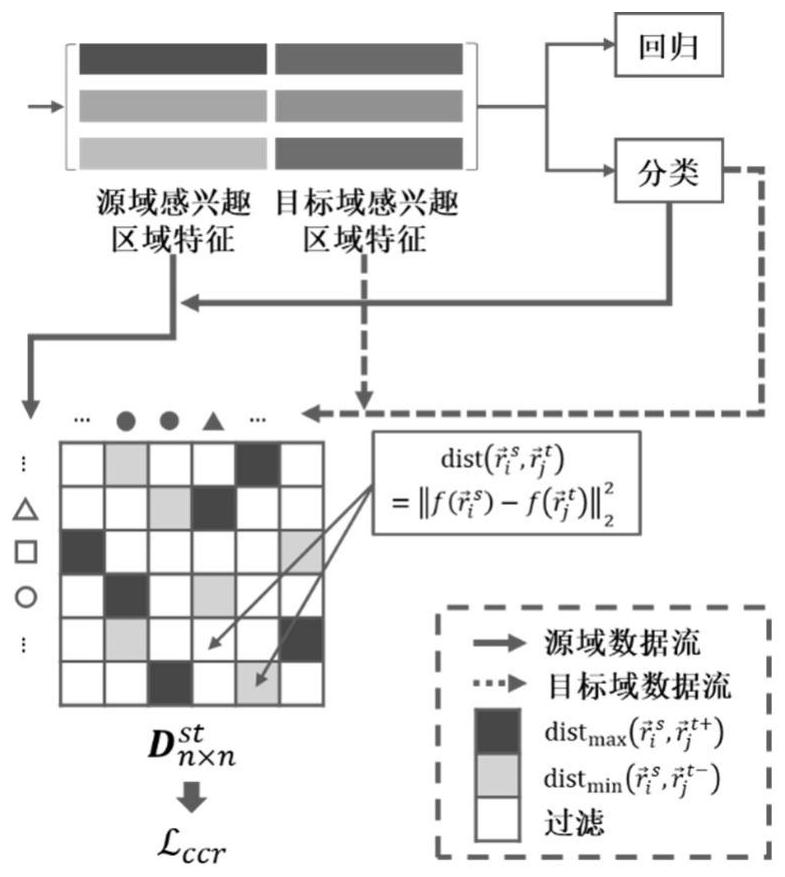

Class regularization method and system for domain adaptive target detection

ActiveCN114386527AReduce distanceIncrease distanceCharacter and pattern recognitionNeural architecturesFeature vectorMachine learning

The invention discloses a category regularization method and system for domain adaptive target detection, and the method comprises the steps: 1, obtaining a source domain region-of-interest feature vector, a target domain region-of-interest feature vector, a corresponding prediction category and a corresponding prediction category; 2, calculating an inter-category regularization loss function value; and step 4, calculating an intra-class regularization loss function value, and combining the intra-class regularization loss function value as a regularization item into a loss function of the domain self-adaptive target detection framework so as to jointly optimize the domain self-adaptive target detection loss function and the class regularization loss function. According to the method, reasonable and sufficient alignment of the same category of features of the two domains is realized, the risk of negative migration of the features of the two domains is greatly reduced, and the method can be flexibly expanded to various existing domain adaptive target detection frameworks.

Owner:湖南大学无锡智能控制研究院

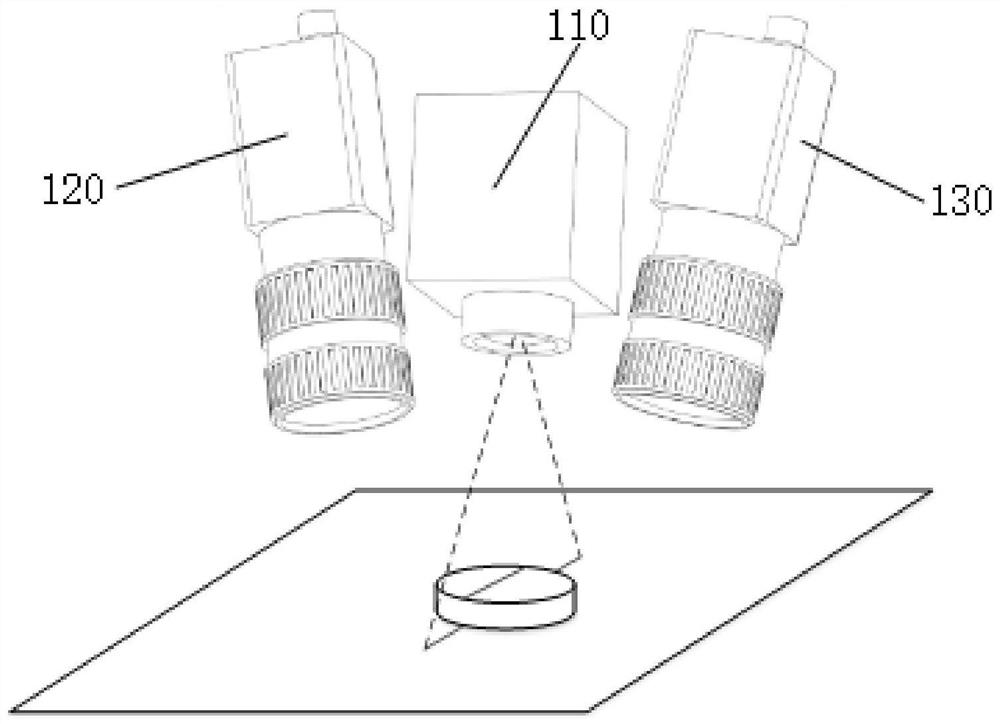

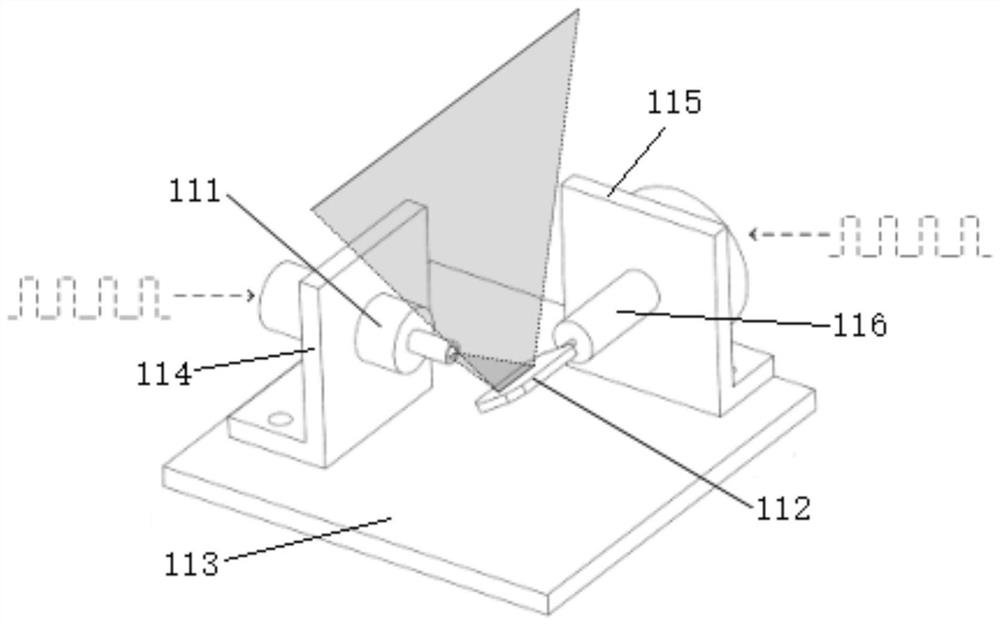

Method for detecting concave-convex amount of aircraft assembly fastener

ActiveCN113624142ALow positioning accuracy requirementsAccurate extractionUsing optical meansAviationPoint cloud

The invention discloses a method for detecting the concave-convex amount of an aircraft assembly fastener, and relates to the technical field of aeronautical manufacturing surface quality detection, and the method comprises the following steps: S1, a detection device is built; s2, synchronous square wave signals are outputted to a line laser and a one-dimensional galvanometer to change the rotating angle of the one-dimensional galvanometer, wherein the one-dimensional galvanometer rotates in a stepping mode, and the line laser is lightened once every time the one-dimensional galvanometer rotates by one angle; s3, every time the line laser is turned on, the first camera and the second camera store images in a local exposure mode, and the sequence of local exposure is recorded; s4, after one-time scanning is completed, the first camera and the second camera transmit images, the images of the first camera and the second camera are matched according to the exposure time sequence, then three-dimensional calculation is conducted, and point cloud data of the fastener area are obtained; and S5, the point cloud data is analyzed, a high point and a low point in the point cloud data are extracted, and the concave-convex quantity is calculated. The method has the advantages of large data coverage area and accurate extraction of the high point and the low point during detection.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Image seamless automatic splicing method against subtitle interference

InactiveCN103020934BAvoid false matchesGood splicing effectImage enhancementGeometric image transformationPerspective transformationVideo image

Owner:WUHAN UNIV

Three-dimensional matching method of landmark points and three-dimensional scanning method for point cloud stitching

ActiveCN104406538BCalculation results are stableAvoid false matchesImage analysisPhotogrammetry/videogrammetryPoint cloudAlgorithm

The invention discloses a three-dimensional mark point matching method for point cloud registration and a three-dimensional scanning method, and belongs to the field of three-dimensional measurement technologies. The three-dimensional mark point matching method comprises the following steps: acquiring three-dimensional coordinate sets P and Q of two visual-angle mark points through a binocular camera; calculating energy of candidate matching points, which are in regard to a point p in the set P, in the set Q; selecting a certain updating strategy according to the 'uniqueness' constraint and the 'spatial feature unchange' constraint; if the matching points found out are all highest in energy and meet a threshold value condition and a restraint condition, ending iteration, otherwise, returning to iteration until the matching points meeting the conditions are found; calculating Euclid transformation according to the matching points, and performing splicing of multi-view point cloud. Compared with other mark point splicing methods, the splicing method has the advantages that the operation is simpler, the number of iteration times is small, 1-2 times of iteration are performed generally, the splicing time is greatly shortened, and a splicing result is stable and reliable under a condition of enough overlapping regions; the three-dimensional mark point matching method can be widely applied to multi-view point cloud data splicing acquired by various sets of measurement equipment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

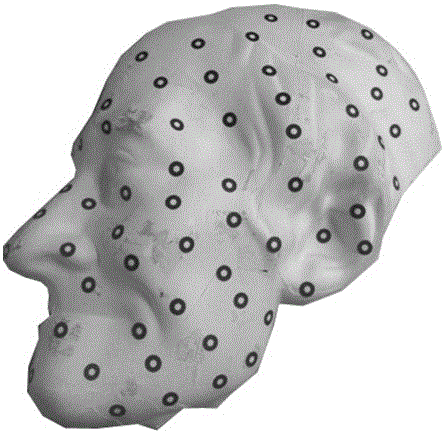

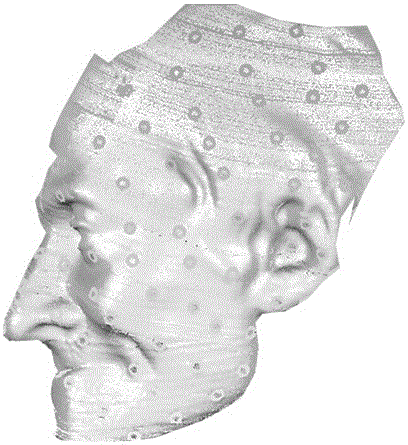

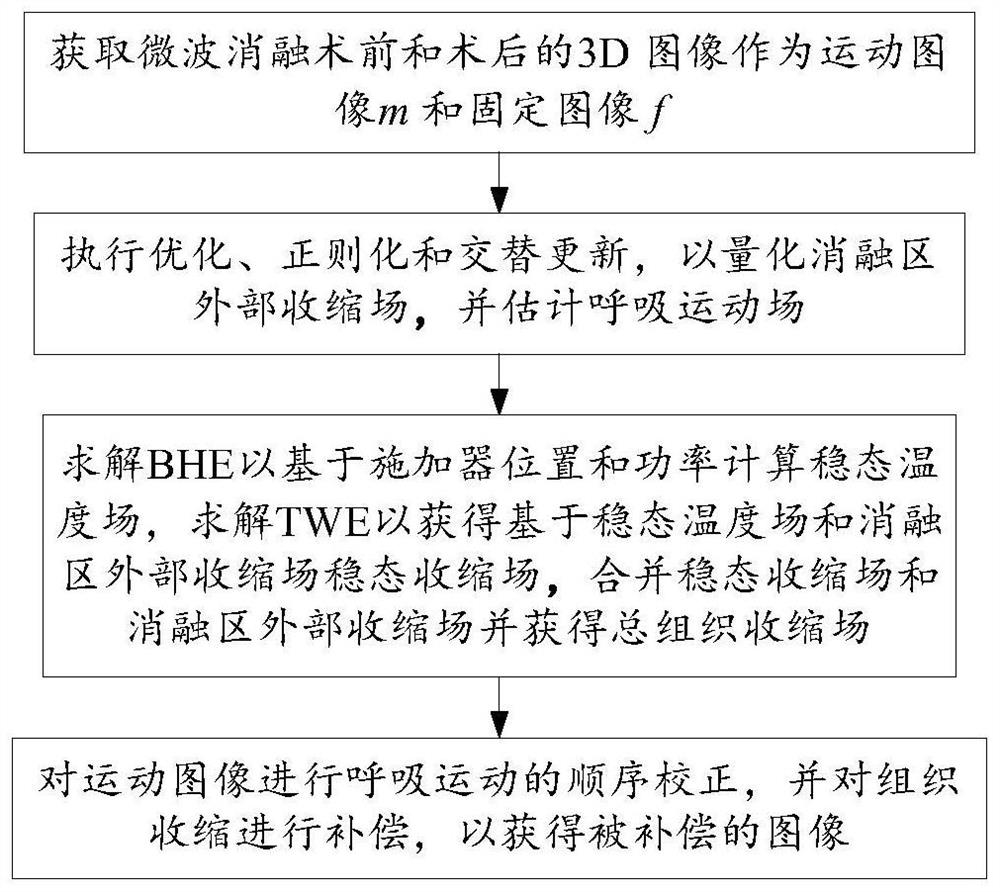

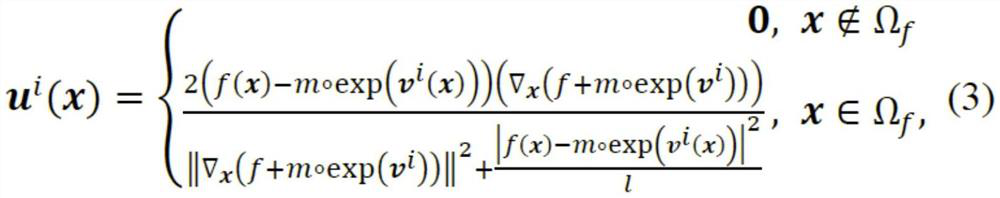

Registration method and device applied to liver ablation postoperative evaluation

PendingCN114757982AAvoid false matchesQuantify external contractionImage enhancementImage analysisMotion field3d image

According to the registration method and device applied to liver ablation postoperative evaluation, wrong matching of an ablation area and a tumor can be prevented, external contraction of the ablation area is quantified, internal contraction of the ablation area is compensated, an image before a microwave ablation operation is aligned with an image after the microwave ablation operation, and the ablation boundary can be evaluated. The method comprises the following steps: (1) acquiring 3D images before and after a microwave ablation operation as a moving image and a fixed image; performing optimization, regularization and alternate updating to quantify the systolic field outside the ablation region and estimate a respiratory motion field; the BHE is solved to calculate a steady-state temperature field based on the position and power of the ablation needle, the TWE is solved to obtain a steady-state contraction field based on the steady-state temperature field and an ablation area external contraction field, the steady-state contraction field and the ablation area external contraction field are combined, and a total tissue contraction field is obtained; and (4) performing sequential correction of respiratory movement on the moving image, and compensating tissue contraction to obtain a compensated image.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

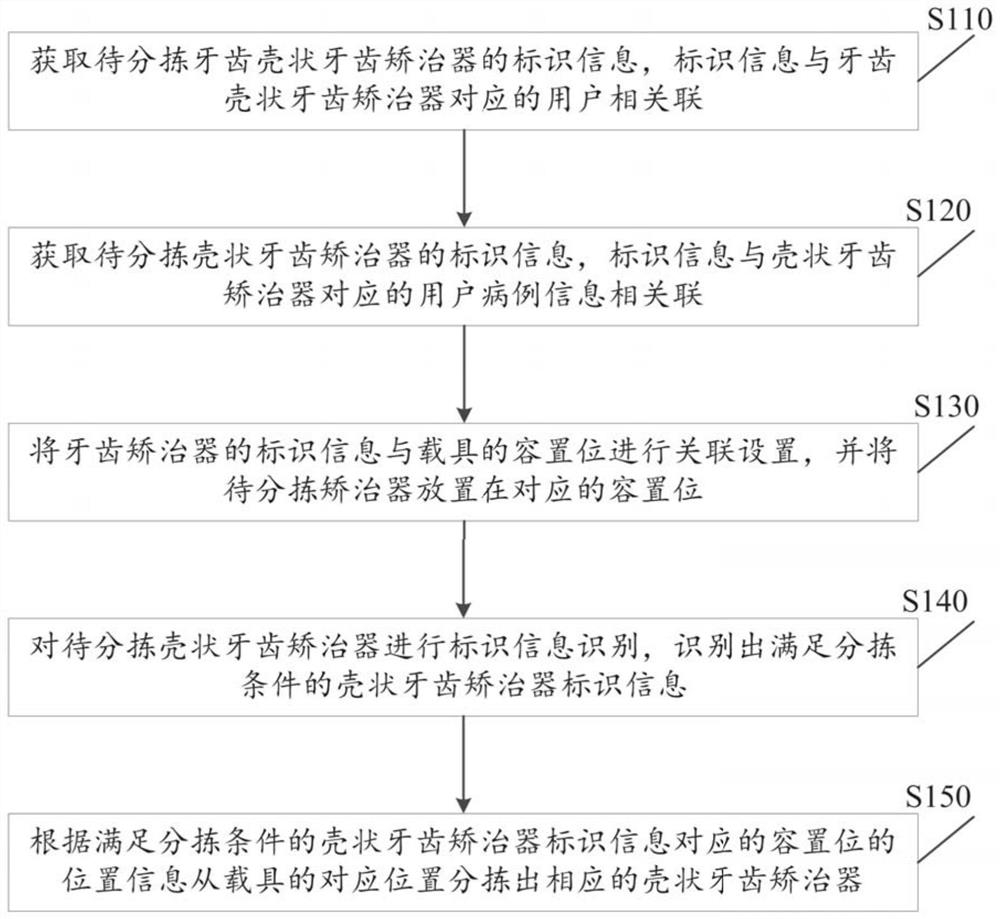

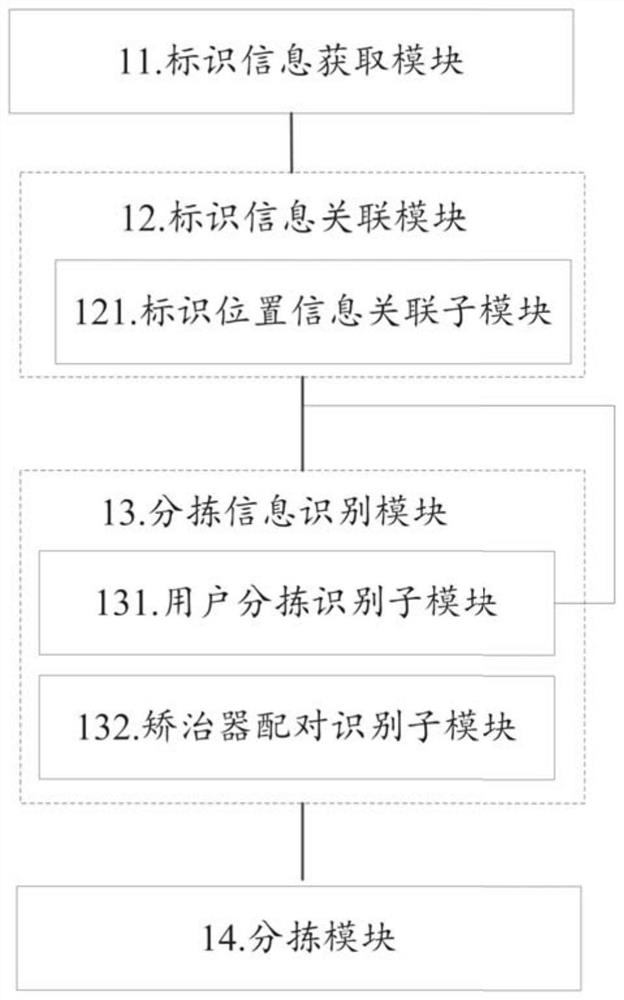

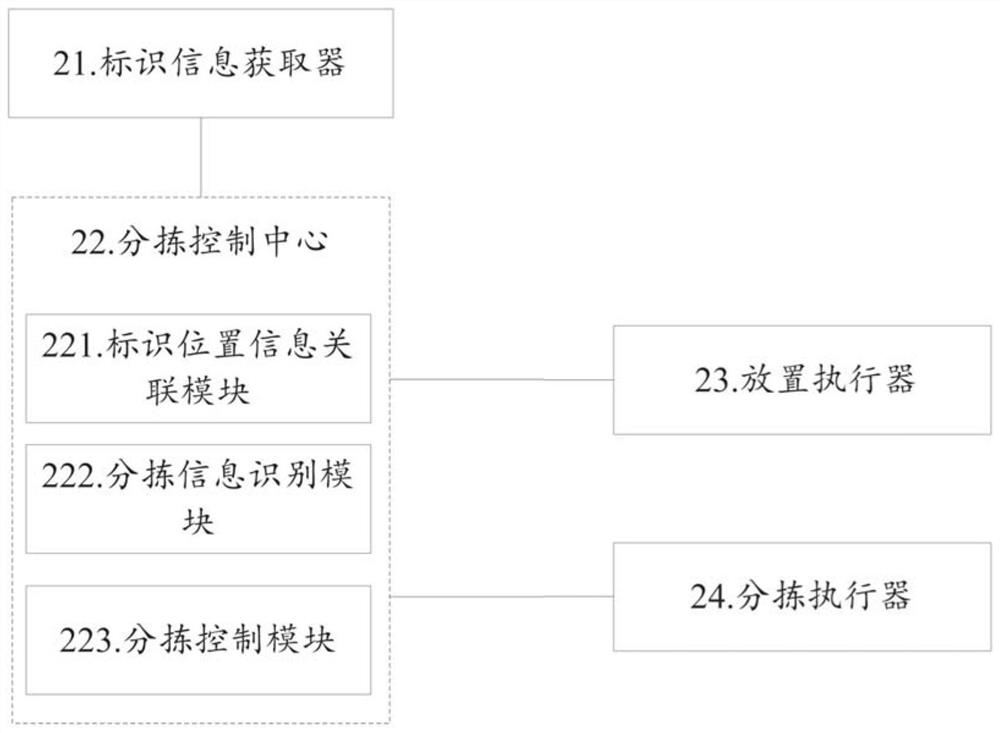

Sorting method, sorting device and sorting equipment for shell-shaped dental appliances

ActiveCN110665822BFast and accurate sortingRealize automatic classification and sortingSortingOral problemsBiomedical engineering

The invention discloses a sorting method, a sorting device and a sorting device for a shell-shaped dental appliance, comprising: obtaining identification information of the shell-shaped dental appliance to be sorted, and the user corresponding to the identification information and the shell-shaped dental appliance Correlation; associate the acquired identification information of the shell-shaped dental appliance to be sorted with the position information of multiple accommodation positions of the shell-shaped dental appliance carrier, and place the shell-shaped dental appliance to be sorted on the The corresponding accommodation position; according to the acquired identification information of the shell-shaped dental appliance to be sorted, the identification information of the shell-shaped dental appliance that meets the sorting condition is identified; according to the corresponding identification information of the shell-shaped dental appliance that meets the sorting condition The position information of the accommodating position sorts out the corresponding shell-shaped dental appliance carrier from the shell-shaped dental appliance carrier. The sorting method and sorting device of the appliance of the present invention solve the technical problem of how to quickly and accurately complete the sorting of a large number of shell-shaped dental appliances manufactured on the production line.

Owner:浙江正雅齿科股份有限公司

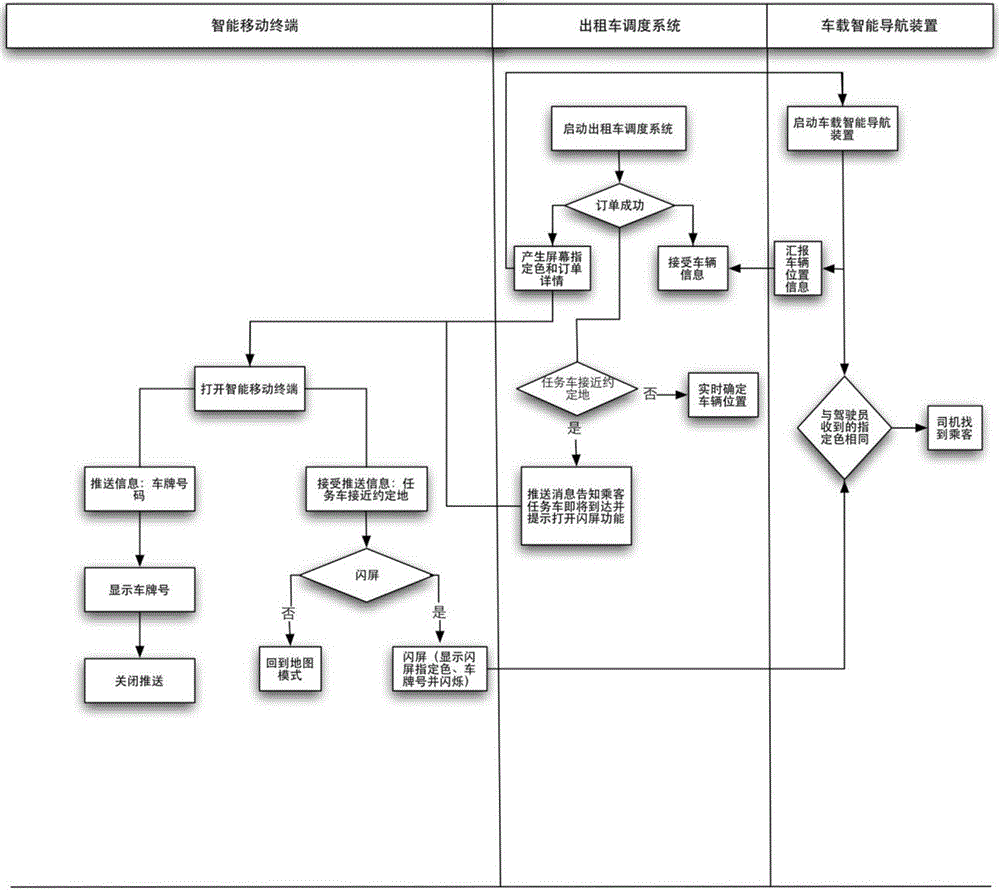

System and method for improving driver-passenger connection efficiency

ActiveCN103489306BImprove efficiencyImprove accuracyData processing applicationsRoad vehicles traffic controlComputer terminalMarine navigation

The invention discloses a system for improving contact efficiency between a driver and a passenger. The system comprises a taxi dispatching system, an intelligent mobile terminal and a vehicle-mounted intelligent navigation unit. The taxi dispatching system is used for checking information like plate number information and real-time position information of a task taxi, and pushing the information to the intelligent mobile terminal. The intelligent mobile terminal is used for receiving the information pushed by the taxi dispatching system and reminding the passenger of turning on a flash screen or not according to the pushed information. The vehicle-mounted intelligent navigation unit is used for sending vehicle real-time position information to the taxi dispatching system, and receiving order information and designated colors of the flash screen pushed by the taxi dispatching system. The invention further discloses a method for improving the contact efficiency between the driver and the passenger. According to the system and the method for improving the contact efficiency between the driver and the passenger, the flash screen designated colors is pushed to the intelligent mobile terminal of the passenger and the vehicle-mounted intelligent navigation unit of the taxi by grasp of two-way data, namely, grasp of passenger information and grasp of taxi information, of the taxi dispatching system, consequently, quick matching between the driver and passenger can be achieved based on the flash screen designated colors, and therefore the contact efficiency and accuracy between the driver and passenger can be improved.

Owner:SHANGHAI FLEETY COMM

Splicing method suitable for video images of multi-focal-length camera

InactiveCN110349084AEasy accessImprove accuracyImage analysisGeometric image transformationCamera imageVideo image

The invention discloses a splicing method suitable for video images of a multi-focal-length camera. The splicing method comprises the following steps: (1) establishing coordinates for the position ofa single camera image of the multi-focal-length camera with a known arrangement mode in a panoramic image; (2) determining an overlapping region between adjacent images, and determining feature pointsof the overlapping region; (3) matching the feature points of the overlapping region, and removing the feature points with wrong matching; and (4) screening the feature points which are correctly matched, and removing the feature points which are wrongly matched again. The panoramic coordinate system is established according to the arrangement positions and the focal lengths of the camera pictures for multi-focal-length camera picture splicing, the specific overlapping area of the adjacent pictures is determined, error matching prone to occurring is avoided to a large extent, and the matchingprocess is accelerated; furthermore, an effective error detection mechanism is provided for a matching result, and the accuracy of multi-focal-length camera image feature matching can be improved.

Owner:上海复瞰科技有限公司

A method, computer-readable medium, and identification system for identifying goods on a shelf

ActiveCN109934093BExpand the receptive fieldAvoid false matchesGeometric image transformationCharacter and pattern recognitionEngineeringData mining

The invention relates to a method for identifying goods on a goods shelf, which comprises the following steps of: S1, shooting the goods on the goods shelf into at least two pictures; S2, detecting commodity characteristics in the picture; S3, establishing a coordinate system, obtaining commodity adjacent pairs, and labeling the adjacent pairs; And S4, carrying out overlapping mapping on the sameannotations in the two adjacent pictures so as to splice all the pictures into one picture, thereby identifying the commodity. The invention also provides a computer readable medium. The invention also provides an identification system.

Owner:创新奇智(南京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com