Catalytic reforming process modeling method based on data and mechanism mixing

A technology of catalytic reforming and modeling methods, which is applied in the field of catalytic reforming process modeling, can solve the problems of difficult mechanism model accuracy, complex catalytic reforming process, and inability to obtain it, and achieve the slow speed of optimization and solution Unable to obtain internal parameters, improve versatility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The present invention will be further analyzed below in conjunction with the accompanying drawings and specific embodiments.

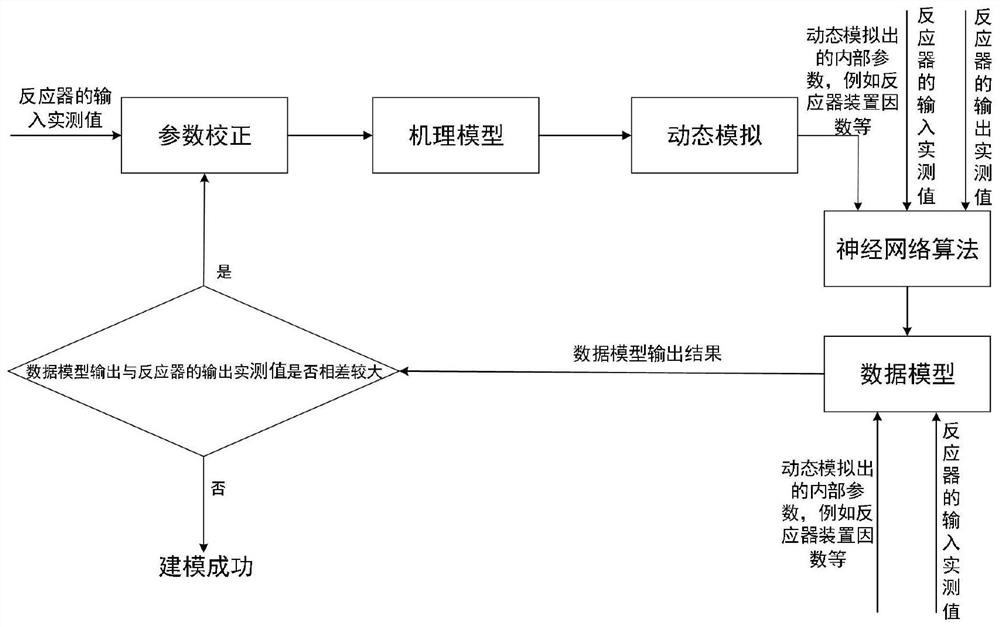

[0113] A method for modeling catalytic reforming processes based on a mixture of data and mechanisms, such as figure 1 Include the following steps:

[0114] Step 1. Establish a mechanism model based on the basic principles of reforming kinetics, thermodynamics, material balance, and energy balance;

[0115] Step 2, in order to make the mechanism model consistent with the actual production process, according to the input measured value of the reactor in the catalytic reforming process, the parameter correction method of the internal point method is used to optimize the model parameters of the mechanism model in step (1);

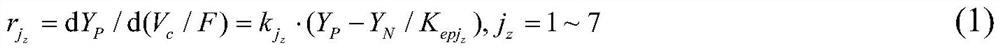

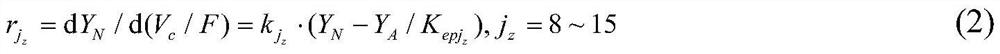

[0116] Step 3, discretize the optimized mechanism model in step (2) to obtain a discrete model; use a solver capable of solving large-scale NLP problems to dynamically simulate the discrete model to obtain internal parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com