Adsorbent for removing boron from desalinated seawater as well as preparation method and application of adsorbent

An adsorbent and seawater technology, which is applied in the field of preparation of new adsorbents, can solve the problems of small molecular weight of NMDG and achieve the effects of convenient magnetic recycling, low cost, and convenient operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] As introduced in the background technology, the current adsorbent has a low removal rate and is not easy to be reused. The preparation process and the adsorption of boron ions in the aqueous solution may cause environmental pollution problems. Therefore, the present invention proposes a preparation method of a novel magnetic deboronation adsorption material, comprising:

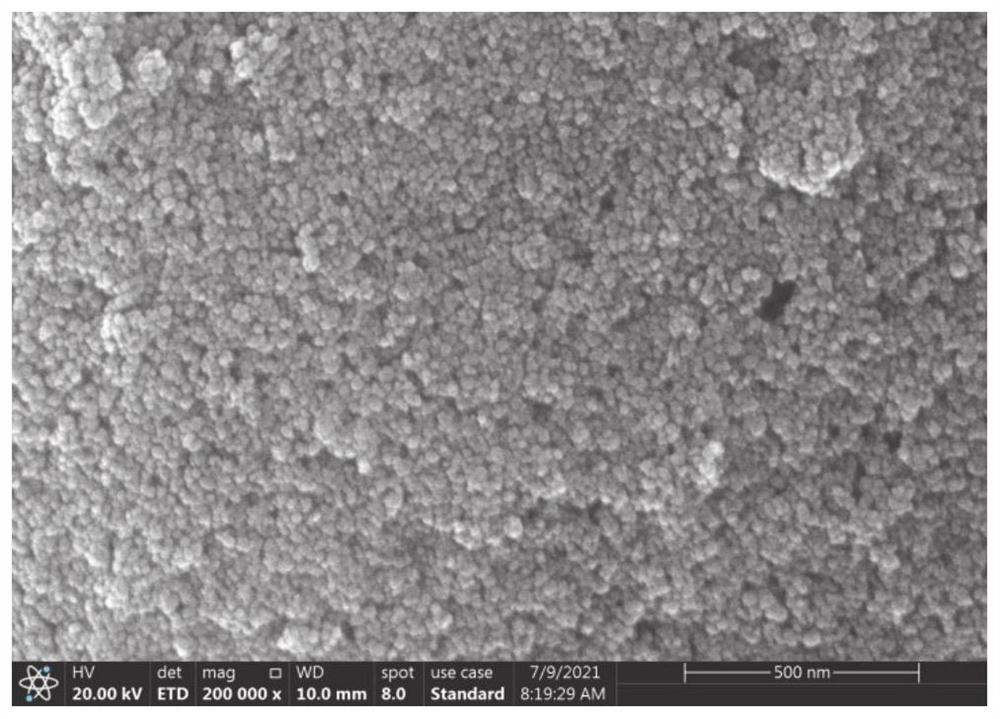

[0024] Preparation of nano ferric oxide particles by co-precipitation method;

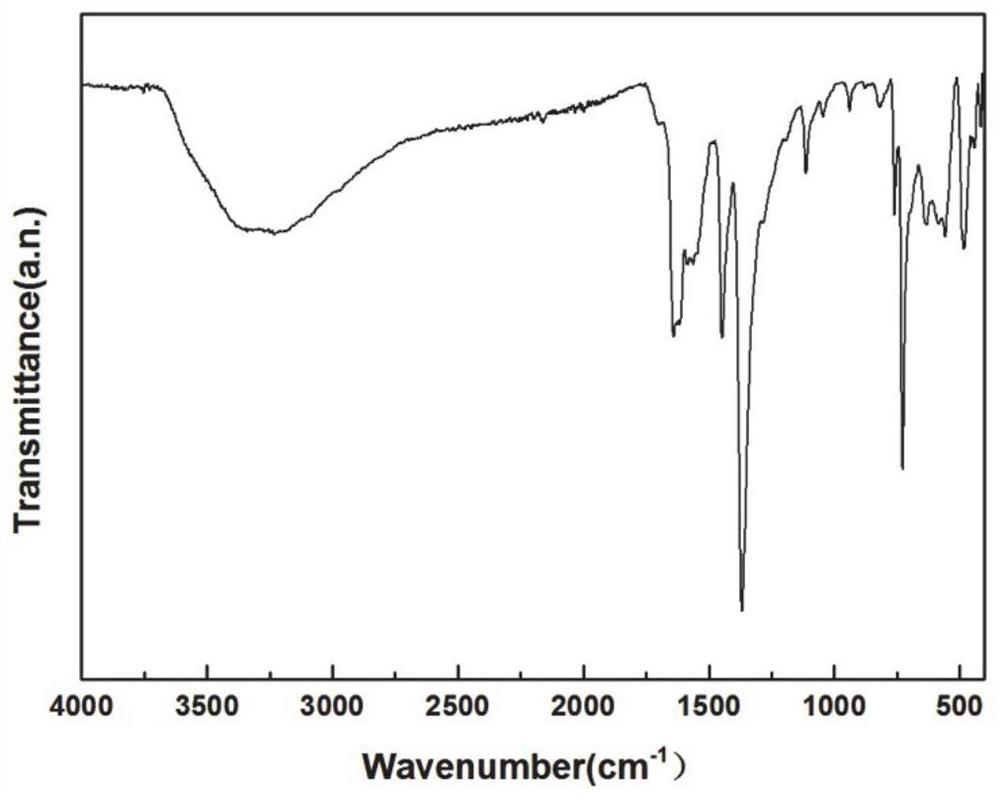

[0025] with SiO 2 Modification of nano ferric oxide particles;

[0026] Composite the modified nano iron ferric oxide particles with N-methylglucosamine to obtain a new type of magnetic adsorbent.

[0027] The application found that the boron removal rate increased with the increase of the amount of adsorbent; with the increase of the oscillation time, it first increased and then slowly tended to be stable; adsorption experiments were carried out at different pH values, and it was found that the adsorption rate under acid...

Embodiment 1

[0047] 1) Preparation experiment:

[0048] FeCl 3 ·6H 2 O, FeSO 4 ·7H 2 O is prepared into a solution containing 0.30mol / L iron salt, put it in a 250mL flask, heat it to 60°C with a water bath, stir and add 0.25mol / L NaOH solution drop by drop, until the pH rises to 9.0, Continue to stir for 30 minutes, after aging for a certain period of time, stop stirring and place a magnet under the three-necked flask for separation, wash with deionized water for 3 times, and dry in vacuum to obtain nano-Fe 3 o 4 . Then 0.5g nano-Fe 3 o 4 Put in a 250mL flask, add 0.6gNa 2 SiO 3 9H 2 O, then add 100 mL of deionized water. Stir and heat the water bath to 60°C, add 0.25mol / L nitric acid solution drop by drop, adjust the pH of the system to about 6.0, heat in the water bath for about 60 minutes, stop stirring, place a magnet under the flask to separate, and wash with deionized water 3 times, the final product was dried in a vacuum oven at 70°C for 12 hours to obtain SiO 2 Pack Fe...

Embodiment 2

[0052] 1) Preparation experiment:

[0053] FeCl 3 ·6H 2 O, FeSO 4 ·7H 2 O is prepared into a solution containing 0.30 mol / L iron salt, placed in a 250 mL flask, heated to 60 ° C with a water bath, stirred and added dropwise with 0.25 mol / L NaOH solution, until the pH rises to 9.2, Continue to stir for 30 minutes, after aging for a certain period of time, stop stirring and place a magnet under the three-necked flask for separation, wash with deionized water for 3 times, and dry in vacuum to obtain nano-Fe 3 o 4 . Then 0.5g nano-Fe 3 o 4 Put in a 250mL flask, add 0.6gNa 2 SiO 3 9H 2 O, then add 100 mL of deionized water. Stir and heat the water bath to 60°C, add 0.25mol / L nitric acid solution drop by drop, adjust the pH of the system to about 6, heat in the water bath for about 60 minutes, stop stirring, place a magnet under the flask to separate, and wash with deionized water 3 times, the final product was dried in a vacuum oven at 70°C for 12 hours to obtain SiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com