Feeding port for bulk machine

A technology of material inlet and bulk machine, which is applied in the field of machinery, can solve the problems of material stuck in the material inlet, unsmooth feeding, and loose fit between the feeding pipe and the loading port of the car, etc., so as to avoid material jamming and blanking smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

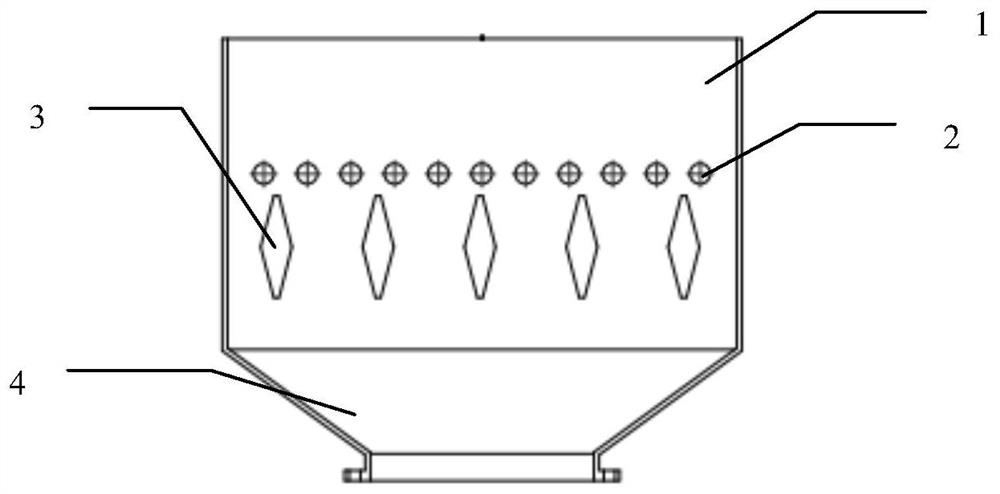

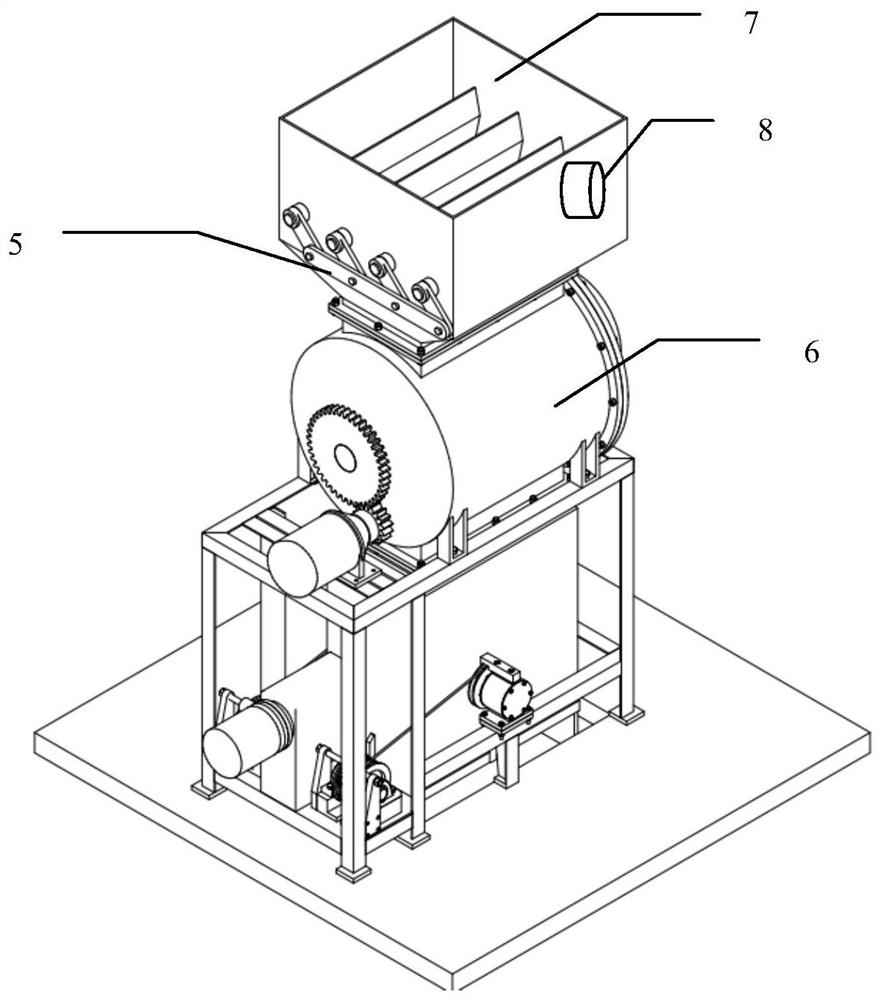

[0020] like figure 1 , 2 Shown, a feed port 7, including feed port wall 1, installation hole 2, louver valve 3, hopper 4, swing device 5, bulk material body 6, vibrator 8.

[0021] The material enters through the material inlet 7, and the wall 1 of the material inlet is connected to the hopper 4, and adopts a rectangular interface with the same caliber size, so that the flow rate of the material is greatly increased, and the working efficiency is improved. The outer wall 1 of the feed port is equipped with a vibrator 8, which is opened when the fluidity of the material is not good, which helps the material to fall smoothly. The louver valve 3 is in the wall 1 of the material inlet, and the installation hole 2 is equipped with a grid screen. Usually, the grid screen is not needed. When the material particles are irregular and the fluidity is not good, the grid screen is placed through the installation hole 2. It acts as a buffer to avoid material jamming at the louver valve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com