Papermaking sludge recycling process and equipment

A technology of papermaking sludge and process, which is applied in the field of papermaking sludge reuse process and equipment, to achieve the effect of reducing cost, low equipment cost and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

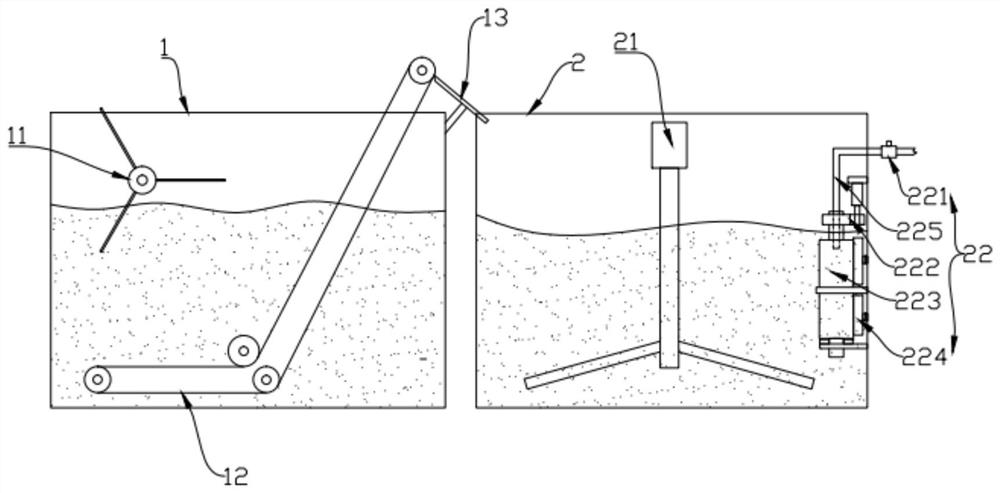

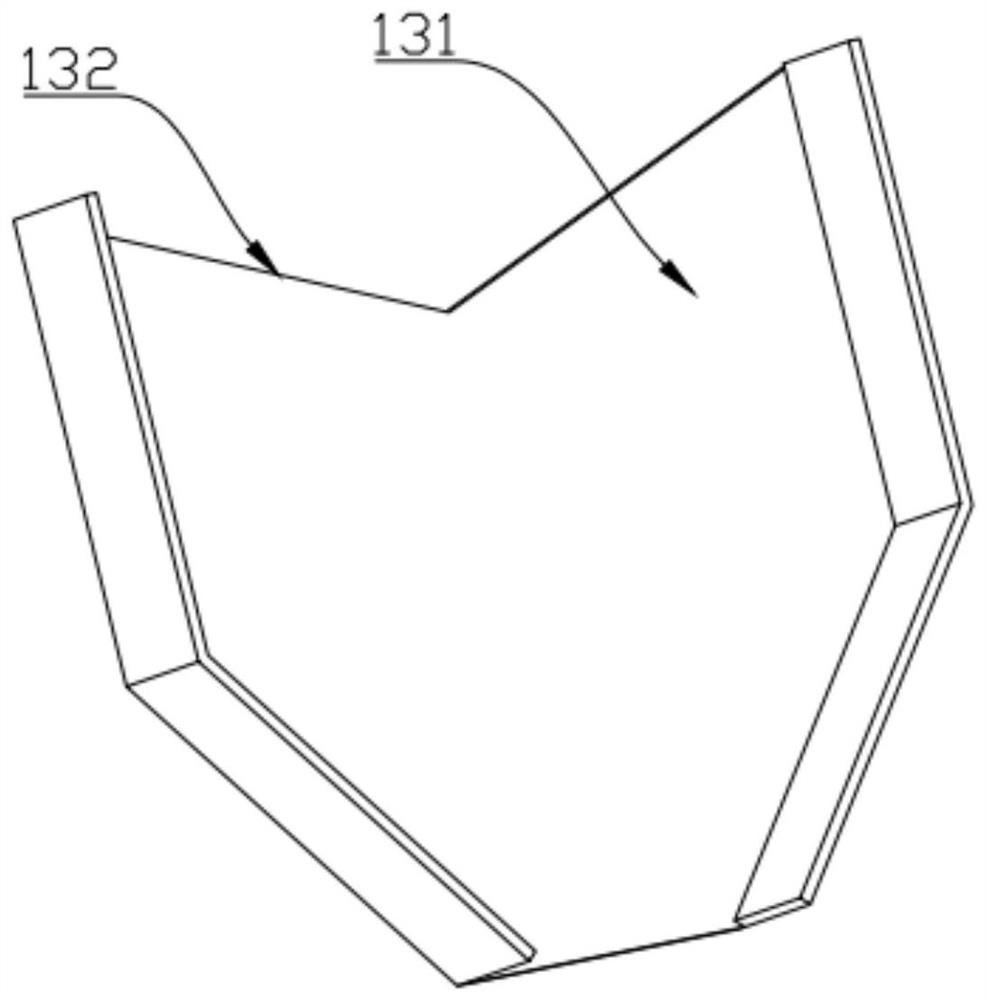

[0023] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

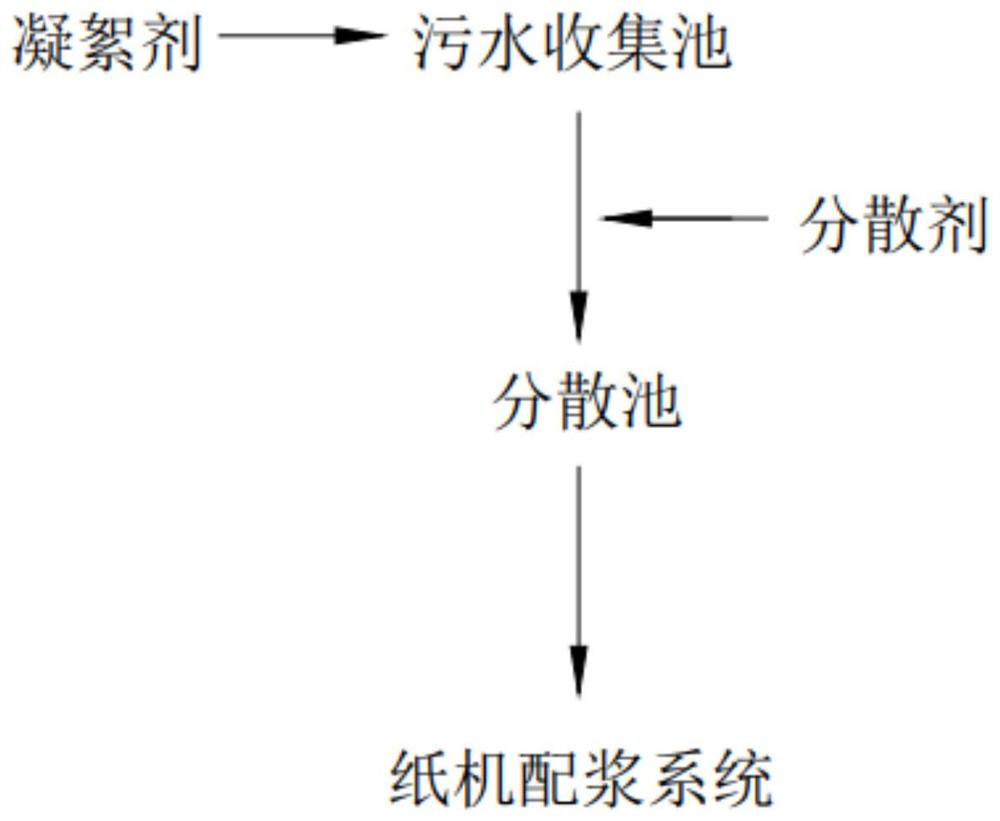

[0024] Pulp needs to be prepared in the papermaking process, commonly known as pulping. Pulping refers to the production process of dissociating plant fiber raw materials into natural or bleached pulp by chemical methods, mechanical methods or a combination of both. In this way, there are a large amount of plant fine fibers in the pulp. During papermaking, part of the plant fine fibers are pressed into paper, but most of the plant fine fibers will be lost with the sewage. These fine fibers have a large surface area, and will be polluted by anaerobic bacteria in the water body for a long time and become sludge, forming solid waste, which wastes a large amount of raw materials, and more importantly, the solid waste also seriously pollutes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com