Copper alloy capable of being riveted and cut and preparation method and application of copper alloy

A cutting and copper alloy technology, applied in the field of electrical plugs, connectors, and low-voltage switches, can solve the problems of poor cutting performance, poor plasticity, and inability to meet customer cutting requirements, so as to achieve improved cutting efficiency, improved cutting performance, The effect of excellent riveting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

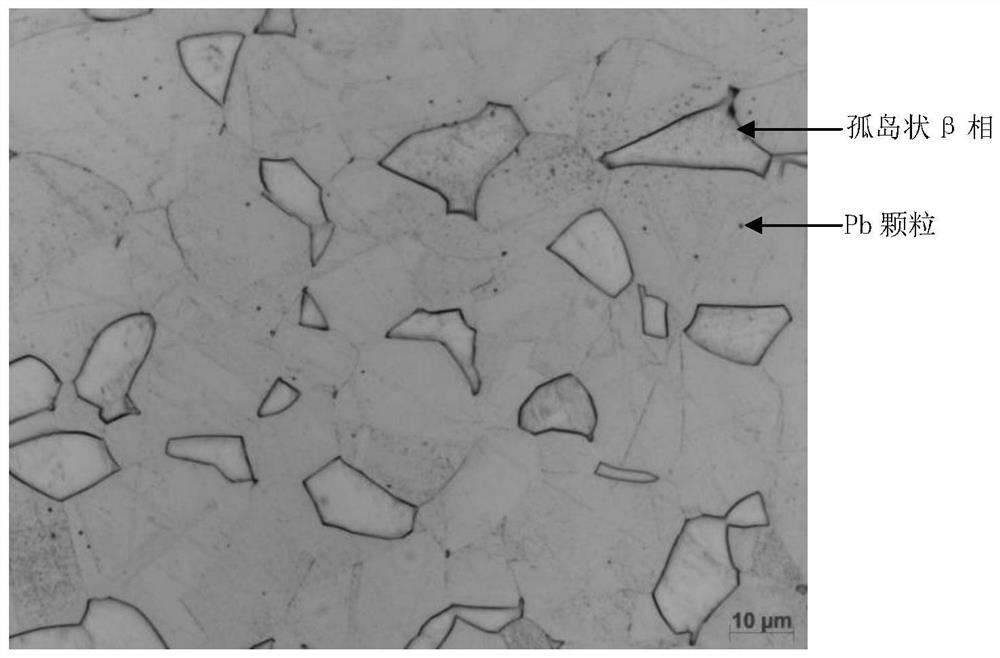

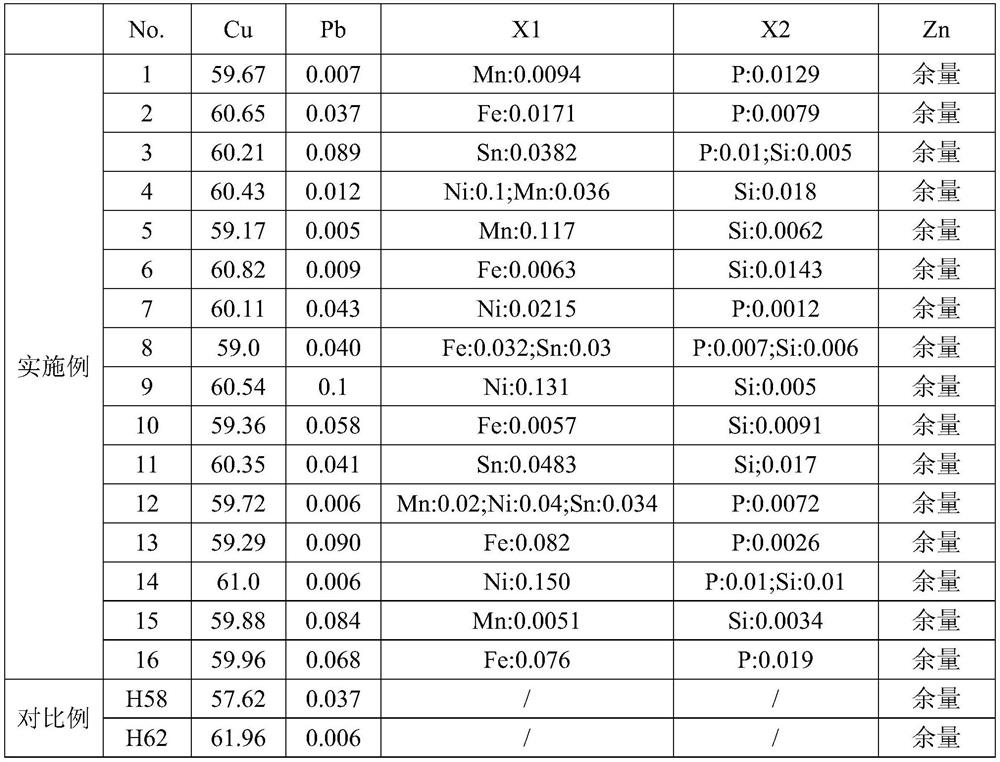

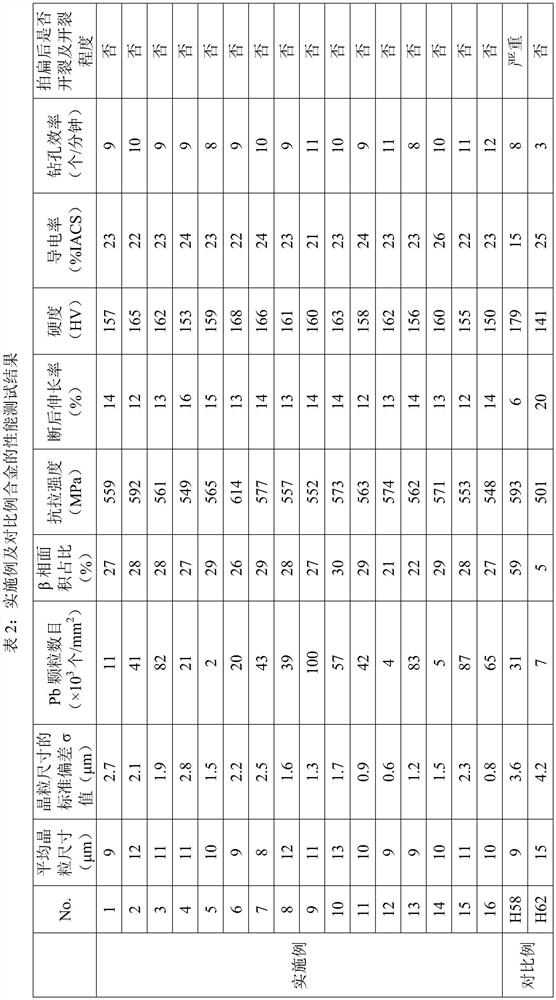

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] According to the composition of the copper alloys of Examples 1 to 16 of the present invention listed in Table 1, the raw materials are all old materials, or a certain proportion of new materials and old materials are used. After smelting, the composition test is carried out, and dilution or compensation is carried out according to the composition test results. After the composition is qualified, the molten copper is introduced into the holding furnace and cast by the way of drawing up. The specification of the billet is The casting temperature is 950~1050℃, and the pulling speed is 1000~1800mm / min. Stretching blanking adopts single-pass interval stretching or multi-mode continuous stretching, stretching to Afterwards, annealing heat treatment is carried out, and more than two stretching + annealing treatments can be carried out acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com