Desert sand heating system and method

A heating system, desert sand technology, applied in solar heating systems, lighting and heating equipment, solar thermal energy, etc., can solve the problems of long sintering time, fast heat dissipation, low efficiency, etc., achieve good heating effect, short heating time, high heat less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

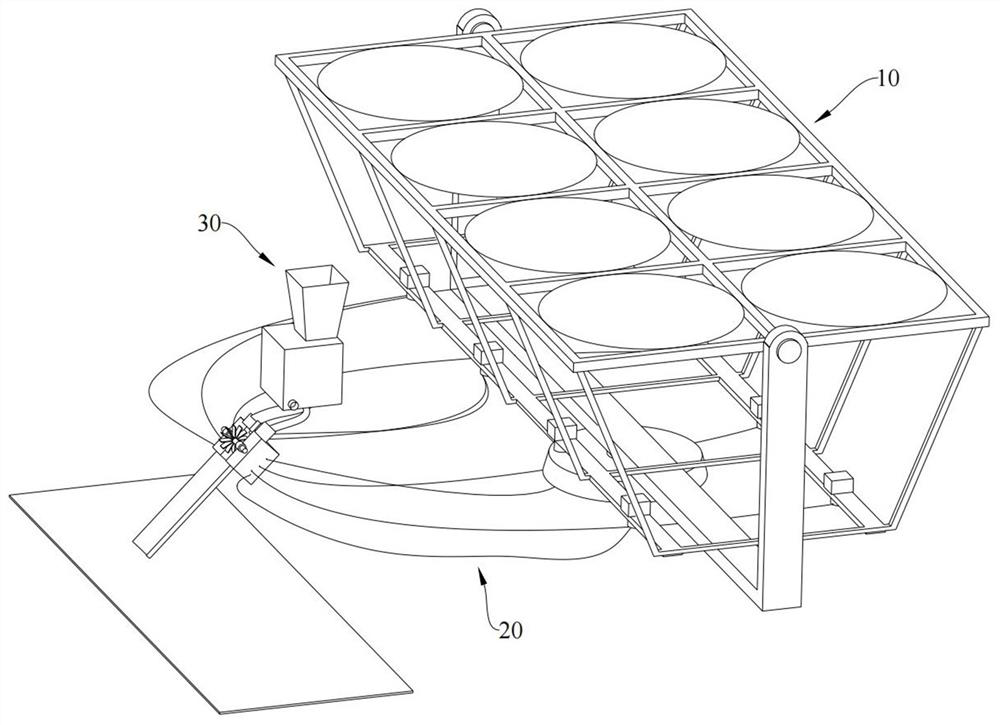

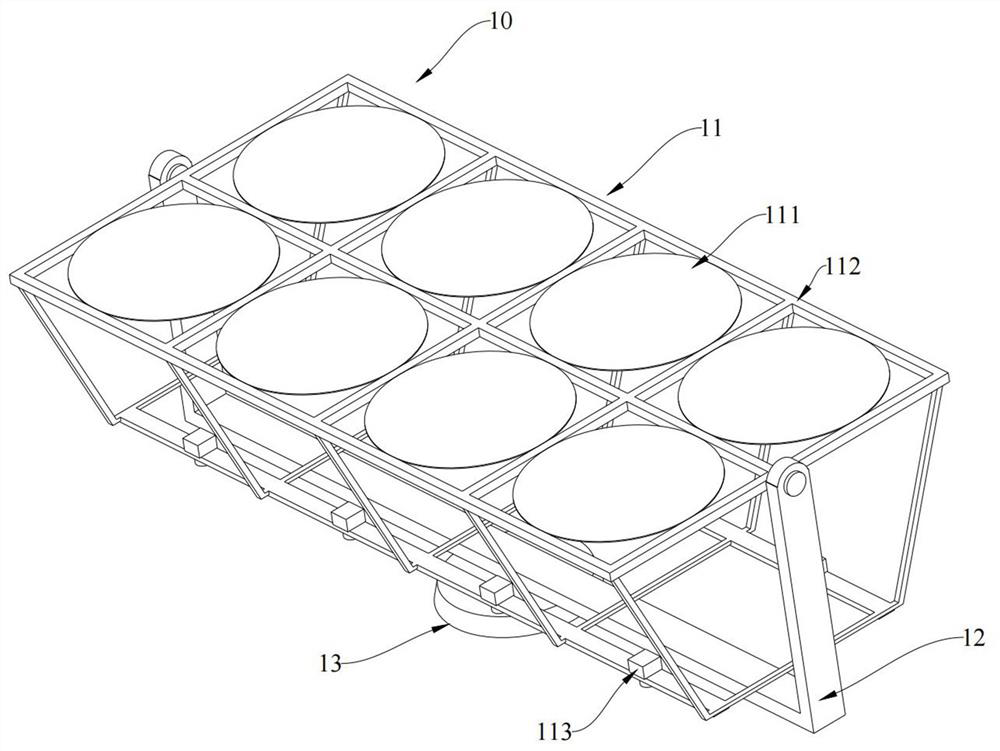

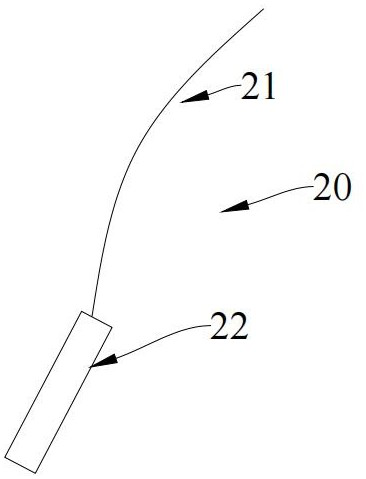

[0042] Such as Figure 1-Figure 7 As shown, Embodiment 1 of the present invention provides a desert sand heating system, including a light concentrating component 10, a light transmission component 20, and a sand melting component 30, and the light concentrating component 10 transmits the collected light through the light transmission component 20 Melting component 30 for sand;

[0043] The sand melting assembly 30 includes a melting device 31 and a classifying device 32;

[0044] The grading device 32 can divide the desert sand into coarse sand and fine sand;

[0045] The melting device 31 includes a melting pool 311 and a scraper member 312. The fine sand can be transported into the melting pool 311 by the first conveying member 321. Grooves 31111 are formed on the surface of the melting pool 311. The coarse sand can be transported by the second transport member 322 into the groove 31111;

[0046] The scraper part 312 is rotatably mounted on the melting pool 311 and locat...

Embodiment 2

[0085] Such as Figure 8 As shown, embodiment 2 of the present invention provides a kind of heating method of desert sand, and described method adopts above-mentioned heating system of desert sand, comprises the following steps:

[0086] Step S10: adjust the light concentrating component 10 to face the sun to obtain light energy; transmit the light energy to the melting pool 311 through the light transmission component 20;

[0087] Step S20: put the desert sand into the feeding device 33, the desert sand enters the classifying device 32 through the feeding device 33, and the desert sand is divided into coarse sand and fine sand by the classifying device 32;

[0088] Step S30: Transport the fine sand to the melting pool 311 for sintering through the first transport member 321, and transport the coarse sand into the groove 31111 of the melting pool 311 through the second transport member, so that the sintered fine sand contacts the coarse sand;

[0089] Step S40: Control the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com