High-vibration-resistance kilohertz miniaturized laser

A laser, high-resistance technology, applied in lasers, laser parts, laser parts and other directions, can solve the problems of reducing the size of the laser, poor adaptability, difficult to meet the high impact and high vibration use environment, etc., and achieve high output peak power. , narrow pulse width, high integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

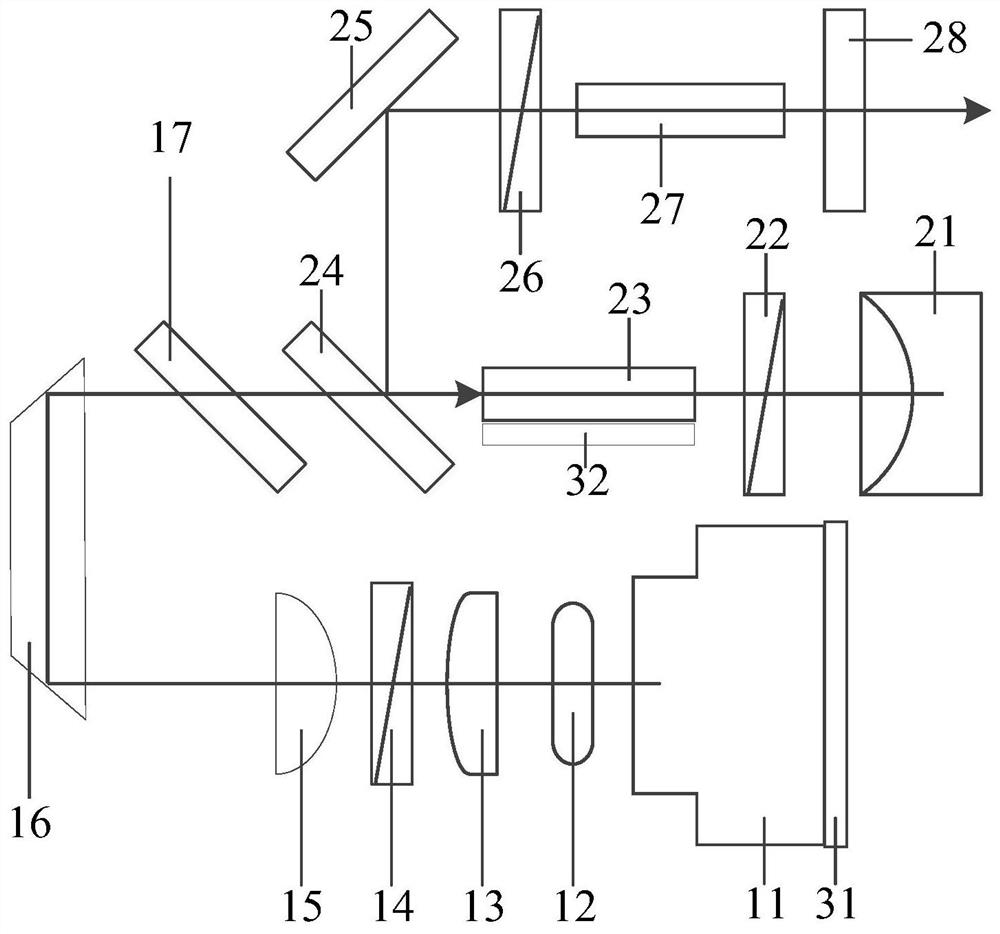

[0069] A high-vibration-resistant kilohertz miniaturized laser, including a pump coupling module 1 and a laser oscillation module 2 arranged on the upper layer of the pump coupling module 1;

[0070] The pump coupling module 1 is used to generate and compress the pump light, change the polarization form and then converge the output. The laser oscillation module 2 is used to receive the pump light output by the pump coupling module 1 and oscillate the pump light to output a laser beam.

Embodiment 2

[0072] like Figure 1-2 As shown, a high-vibration-resistant kilohertz miniaturized laser includes a pump coupling module 1, a laser oscillation module 2 arranged on the upper layer of the pump coupling module 1, and a thermal control module 3 for temperature control;

[0073] The pump coupling module 1 is used to generate and compress the pump light, change the polarization form and then converge the output, and the laser oscillation module 2 is used to receive the pump light output by the pump coupling module 1 and oscillate the pump light to output a laser beam;

[0074] The pump coupling module 1 includes a laser diode stack 11, a waveguide shaping device 12, a cylindrical mirror 13, a second quarter-wave plate 14, a convex lens 15, a Dove prism 16 and a second 45° optically connected sequentially. dichroic mirror 17,

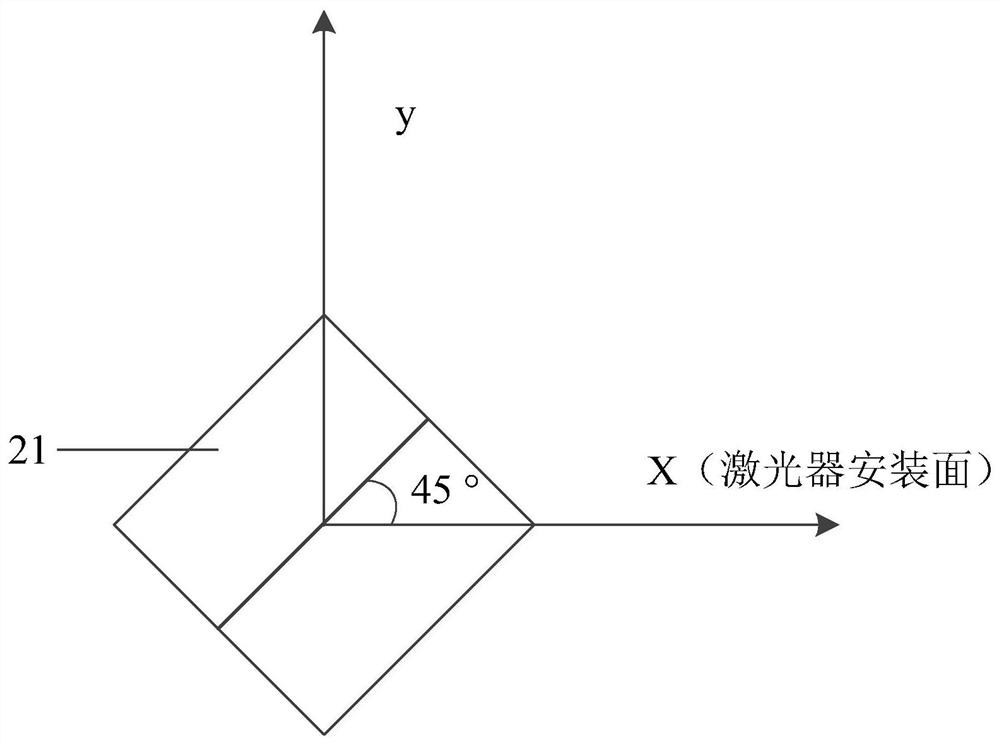

[0075] The second 45 ° dichroic mirror 17 and the output optical path of Dove prism 16 are at an angle of 45 °, the first 45 ° dichroic mirror 24 is arran...

Embodiment 3

[0101] like Figure 1-2 As shown, a high-vibration-resistant kilohertz miniaturized laser is used in lidar and laser guidance systems. The laser is divided into upper and lower layers, such as figure 1 and figure 2 As shown, the device specifically includes the following components: pump coupling module 1 (including 11, 12, 13, 14, 15, 16, 17), laser oscillation module 2 (including 21, 22, 23, 24, 25, 26, 27, 28) and temperature control module 3 (including 31 and 32);

[0102] The pump coupling module 1 consists of a laser diode stack 11, a waveguide shaping device 12, a cylindrical mirror 13, a second quarter-wave plate 14, a convex lens 15, a Dove prism 16 and a second 45° dichroic mirror 17 composition;

[0103] The pump light emitted by the laser diode stack 11 is compressed by the fast axis of the waveguide shaping device 12, then compressed by the slow axis of the cylindrical mirror 13, and the compressed pump light becomes elliptically polarized by the second quarte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com