Pre-lithiation reaction chamber apparatus

A pre-lithiation and reaction chamber technology, which is applied in the field of pre-lithiation reaction chamber equipment, can solve the difficult problems of drying chamber water content and control, achieve excellent initial Coulombic efficiency and cycle capacity retention, and suppress damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

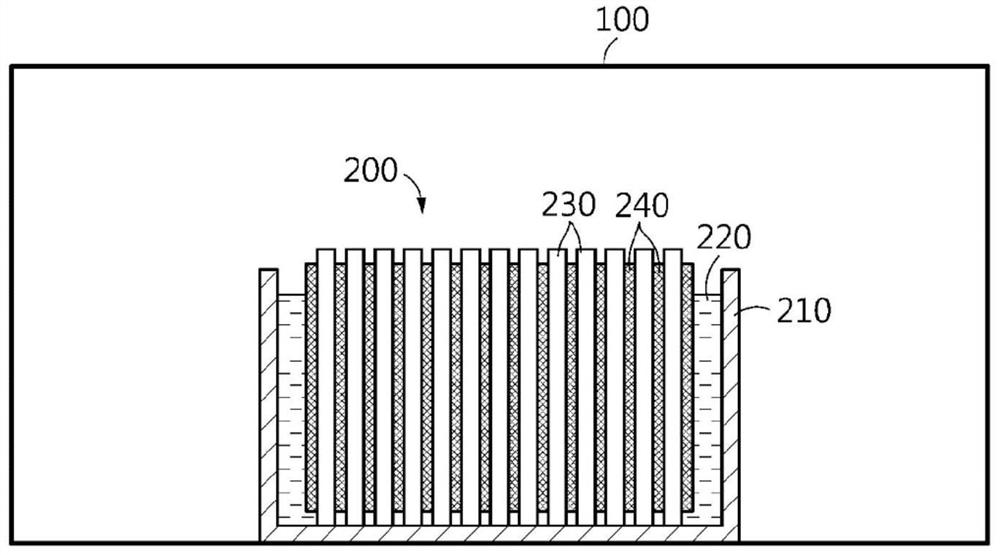

Image

Examples

Embodiment 1

[0098]

[0099] First, 95% by weight of graphite as a negative electrode active material, as 5% by weight of DENKABLACK, as a binder, as a thickener, 1.5 as a thickener The weight% of CMC was added to the water to prepare a negative slurry. The negative slurry was applied to the copper collector and vacuum dried at 120 ° C, and then pressed, thereby obtaining a negative electrode.

[0100]

[0101] In order to use the negative electrode (5 × 5 cm 2 ) And as a lithium metal of the electrodes performed pre-lithium-containing mixed organic solvents containing dissolved in a mixed organic solvent dissolved in carbonate (EC) / carbonate (EMC) = 1 / 9 (volume ratio). M LIPF 6 Electrolyte.

[0102]

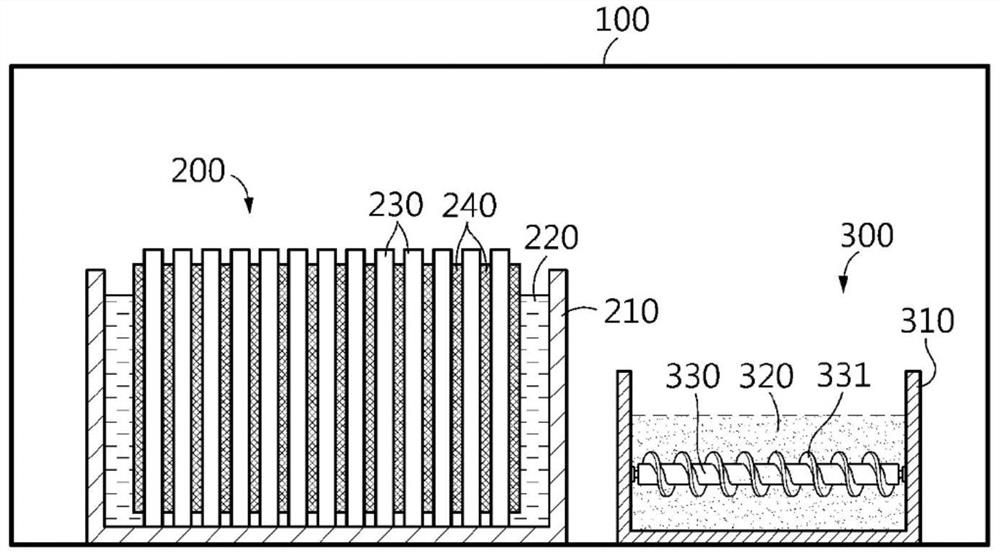

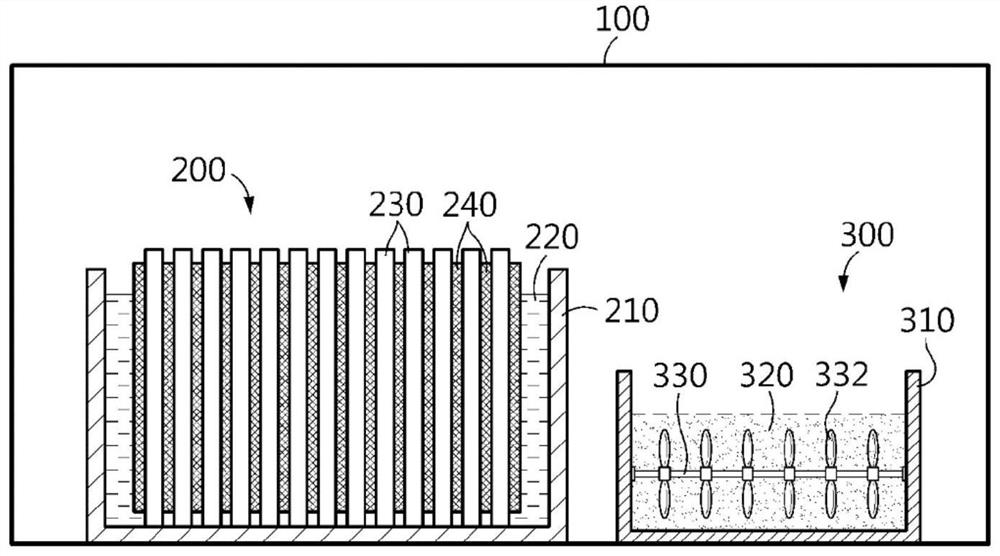

[0103] As a pipette, prepare figure 2 The container made of SUS is made and has a cube shape on the top side opening, and the rotating shaft is mounted on the inner wall of the container and mounted a position change member having a helix formed on the rotating shaft. Then, 100 g of pentoxi...

Embodiment 2

[0109] Pre-lithiuming is performed in the same manner as in Example 1 to provide a pre-lithiuming negative electrode, and the difference is that 2 mA / cm is applied in the pre-lithiuming step. 2 Current density. The lithium secondary battery is obtained using this pre-lithiuming negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com