Preparation method for producing ossein in flavoring agent through enzymatic degradation of livestock bones

A technology of enzymatic degradation and flavoring agent, used in food ingredients as chelating agents, food ingredients as antioxidants, food science, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for producing osteotin in seasonings by enzymatically degrading livestock bones, comprising the following steps:

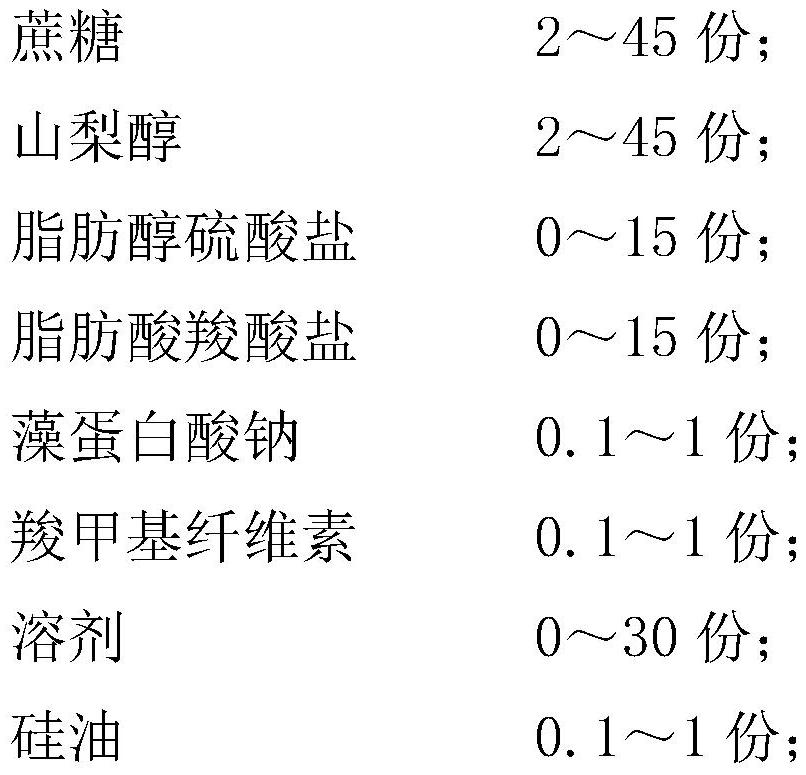

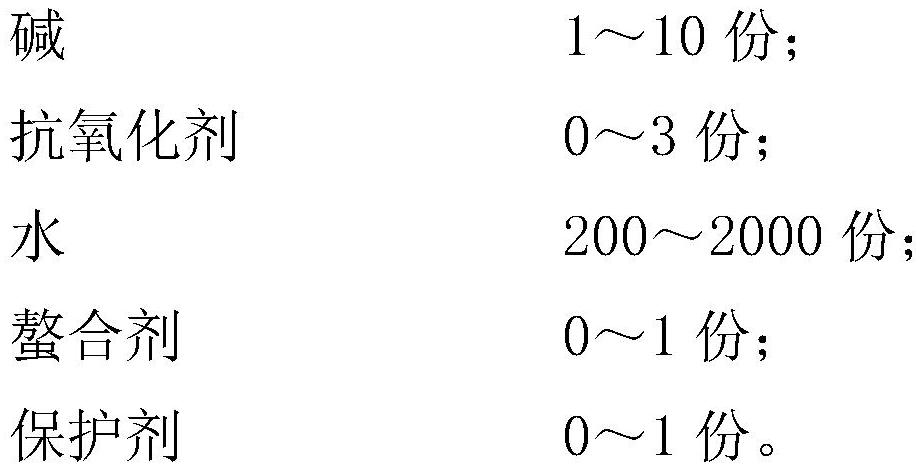

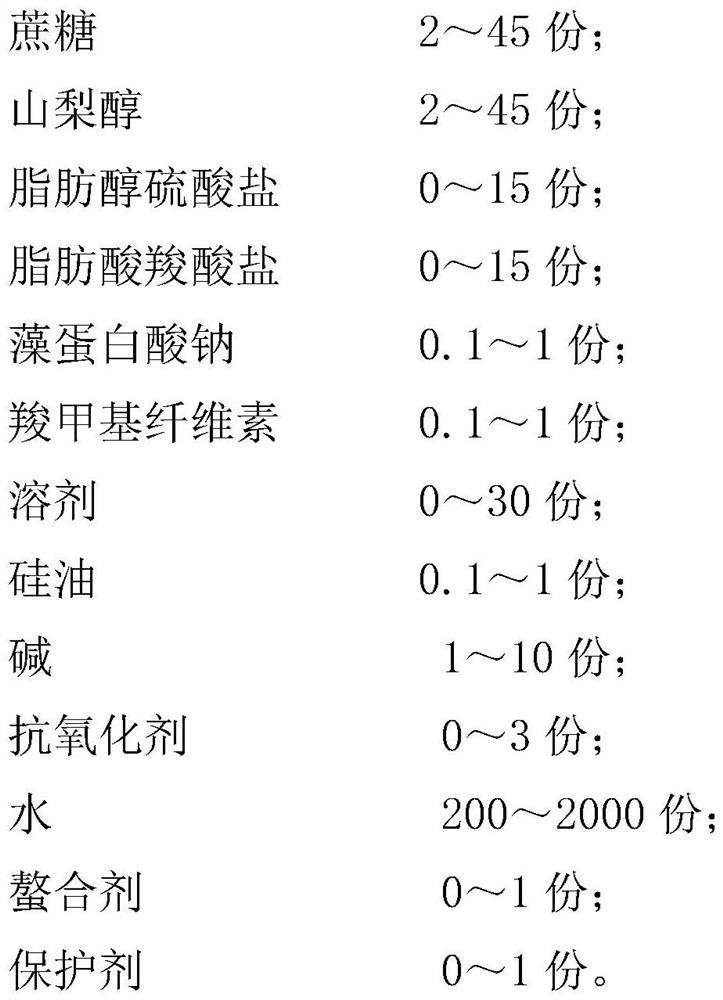

[0030] 1) Screening, cleaning the bones of the livestock, putting them into a purification pool filled with a remover, soaking for 1 to 3 hours, taking out and washing to obtain bone raw materials, the remover includes sucrose, sorbitol, Fatty alcohol sulfate, fatty acid carboxylate, sodium alginate, carboxymethyl cellulose, solvent, silicone oil, alkali, antioxidant, water, chelating agent and protective agent;

[0031] 2) crushing, crushing the bone material to 30-50mm, the crushing method adopts one of the methods of mechanical crushing or liquid nitrogen low-temperature crushing;

[0032] 3) Secondary cleaning, washing the crushed aggregate and draining the water;

[0033] 4) Enzymolysis, the drained aggregate is put into the enzymolysis tank, and the enzymolysis solution and water are put into the enzymolysis tank, the pH value is...

Embodiment 1

[0051] 1) Screening, cleaning the bones of the livestock, putting them into a purification pool filled with a remover, soaking for 1 to 3 hours, taking out and washing to obtain bone raw materials, the remover includes sucrose, sorbitol, Fatty alcohol sulfate, fatty acid carboxylate, sodium alginate, carboxymethyl cellulose, solvent, silicone oil, alkali, antioxidant, water, chelating agent and protective agent;

[0052] 2) crushing, crushing the bone material to 30mm, the crushing method adopts one of the methods of mechanical crushing or liquid nitrogen low-temperature crushing;

[0053] 3) Secondary cleaning, washing the crushed aggregate and draining the water;

[0054] 4) Enzymolysis, the drained aggregate is put into the enzymolysis tank, and the enzymolysis solution and water are put into the enzymolysis tank, the pH value is 7-7.9, the enzymolysis temperature is 50-55°C, the weight of the aggregate and water The ratio is 1:1, the enzymolysis solution added is 220~270U...

Embodiment 2

[0069] 1) Screening, cleaning the bones of the livestock, putting them into a purification pool filled with a remover, soaking for 1 to 3 hours, taking out and washing to obtain bone raw materials, the remover includes sucrose, sorbitol, Fatty alcohol sulfate, fatty acid carboxylate, sodium alginate, carboxymethyl cellulose, solvent, silicone oil, alkali, antioxidant, water, chelating agent and protective agent;

[0070] 2) crushing, crushing the bone material to 50mm, the crushing method adopts one of the methods of mechanical crushing or liquid nitrogen low-temperature crushing;

[0071] 3) Secondary cleaning, washing the crushed aggregate and draining the water;

[0072] 4) Enzymolysis, the drained aggregate is put into the enzymolysis tank, and the enzymolysis solution and water are put into the enzymolysis tank, the pH value is 7-7.9, the enzymolysis temperature is 50-55°C, the weight of the aggregate and water The ratio is 1:3, the enzymolysis solution added is 220~270U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com