Multi-station bottle blowing machine without moving mold locking frame

A bottle blowing machine and multi-station technology, which is applied in the field of rubber and plastic machinery, can solve the problems of energy waste, large energy consumption, and large motion inertia, and achieve the effects of reducing vibration and energy consumption, increasing single-machine output, and small motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

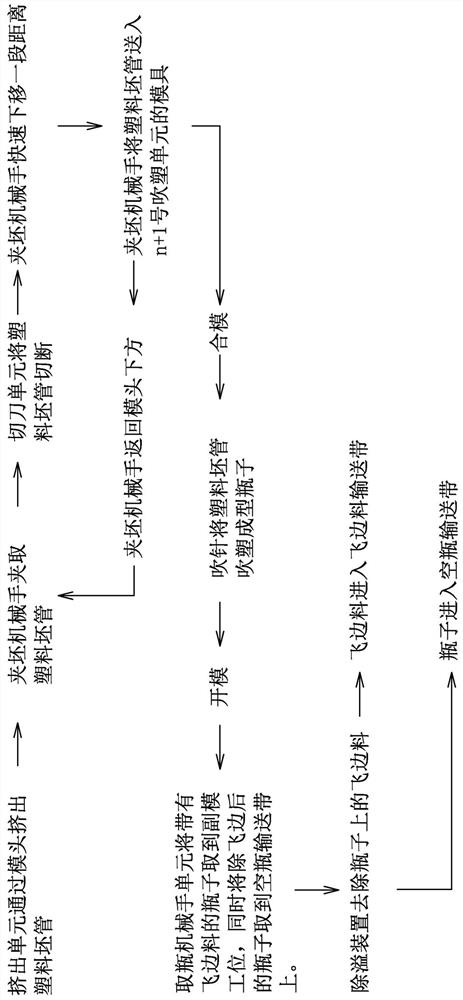

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

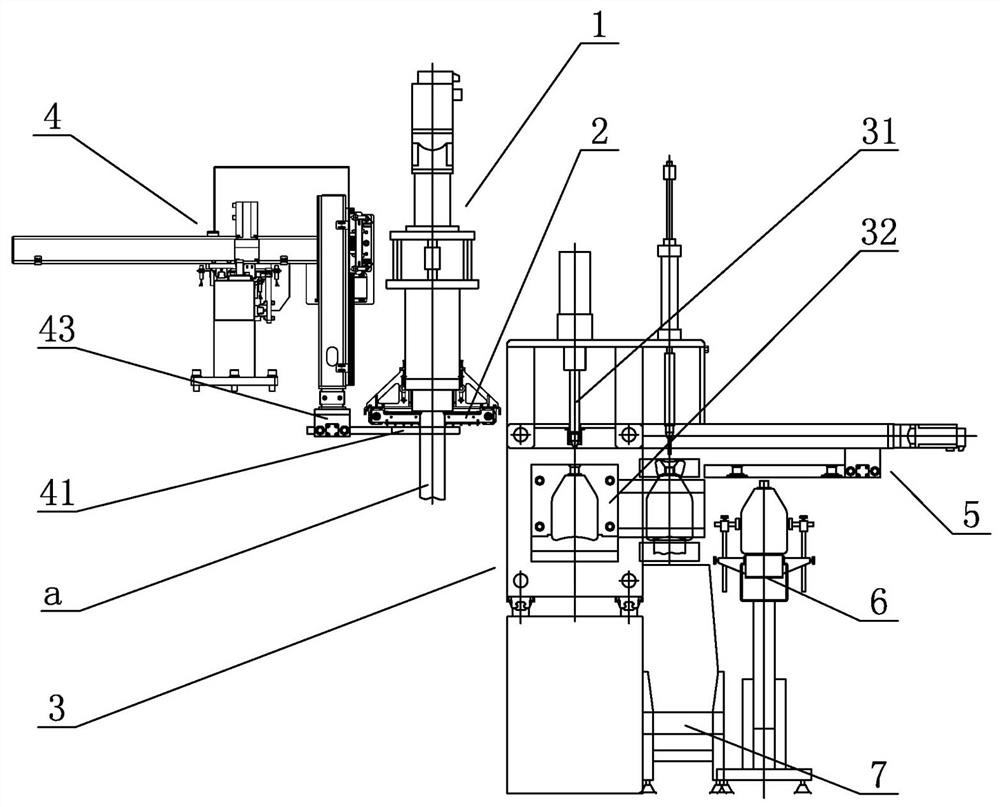

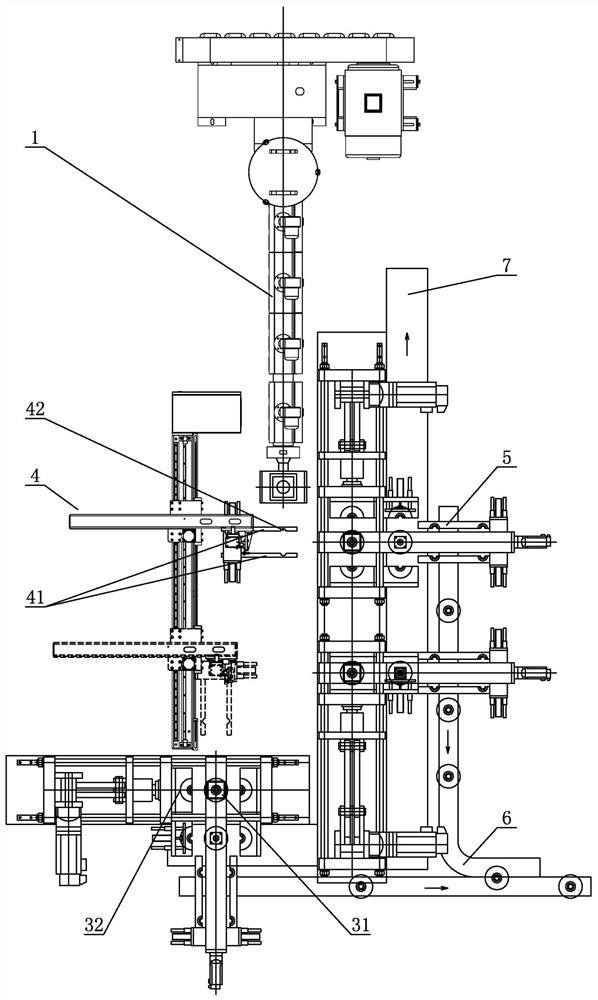

[0024] Such as figure 1 with figure 2 As shown, the multi-station blow molding machine in this embodiment does not move the clamping frame, including an extrusion unit 1, a cutter unit 2, three blow molding units 3, a clamping manipulator unit 4, and a take-off unit. Bottle manipulator unit 5, empty bottle conveyor belt 6 and flash conveyor belt 7.

[0025] The extruding unit 1 has an extruding die and a blowing pipe for extruding a hollow plastic blank tube a.

[0026] The cutter unit 2 is used to cut off the plastic blank tube a.

[0027] The blow molding unit 3 is used for blow molding the plastic blank tube a into a bottle. Each blow molding unit 3 has a frame and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com