Production process of functional shrimp and crab starter feed and intelligent production equipment thereof

A technology of production equipment and open feed, which is applied in the extrusion and granulation of raw materials, the molding or processing of animal feed, and feed, etc., and can solve the problems of water pollution, death, intestinal infarction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solution in the present invention will be described below with reference to the drawings and embodiments.

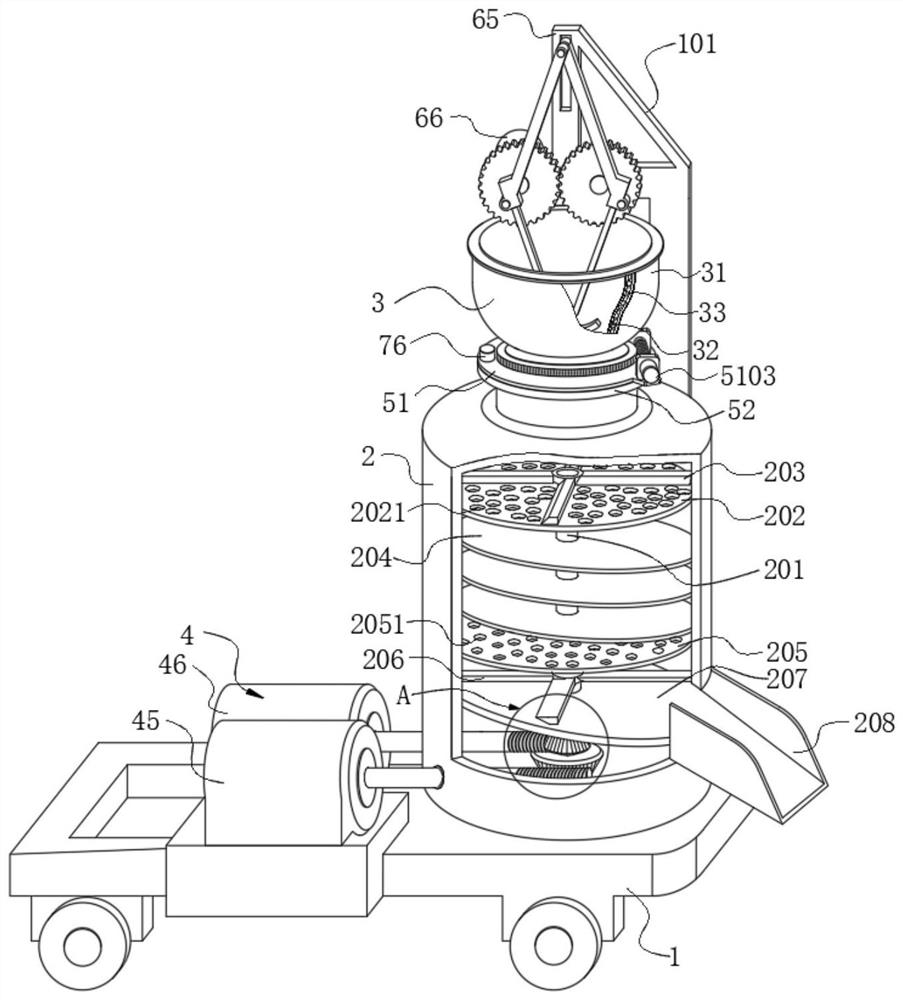

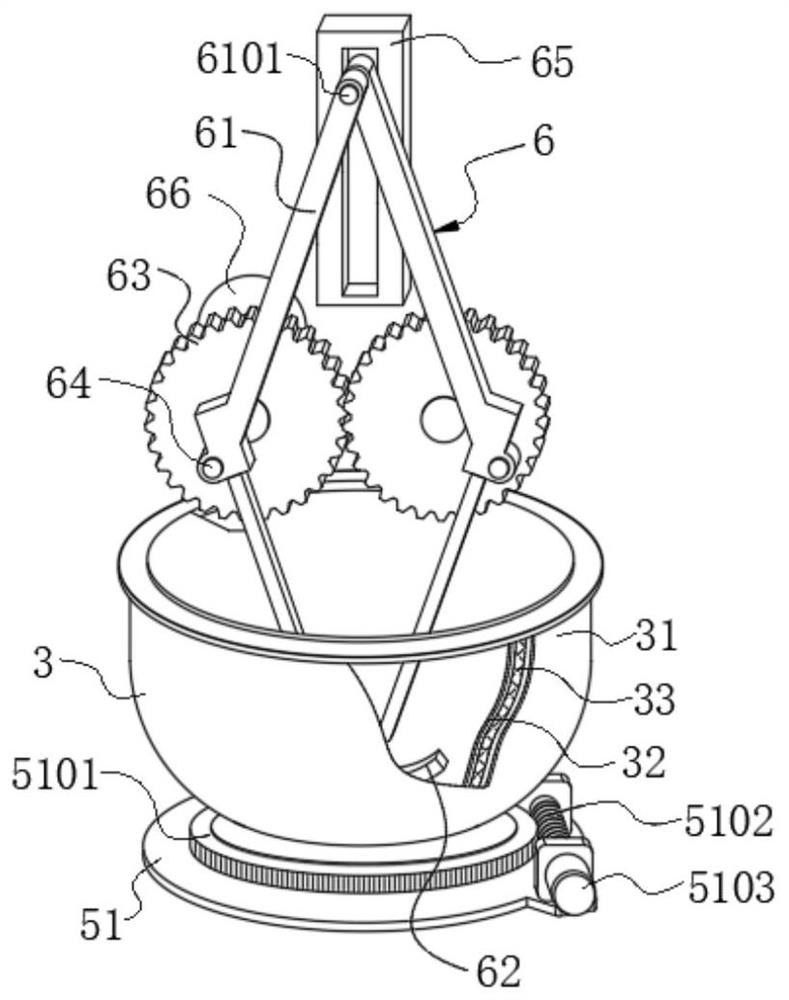

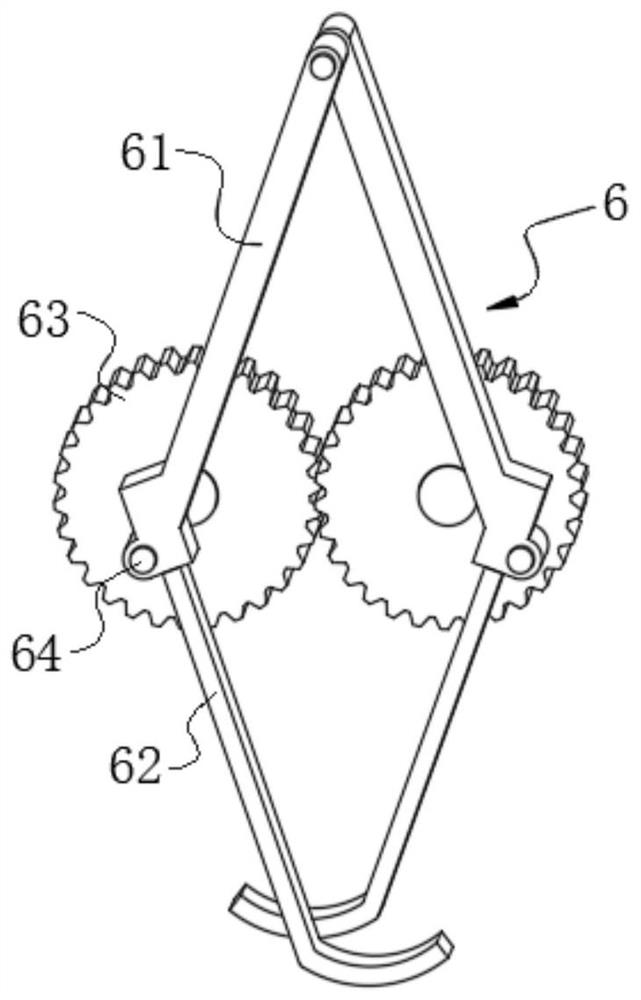

[0056] see Figure 1-6 , the present invention provides a technical solution: an intelligent production equipment for functional shrimp and crab opening materials, including a base 1, a top frame 101 fixedly installed on the top of the base 1, and a manufacturing machine fixed on the base 1 and capable of horizontal and free rotation. The granulation cylinder 2; the mixing bucket 3 fixedly arranged above the feeding port of the granulation cylinder 2; the stirring structure 6 installed on the top frame 101 and extending into the mixing bucket 3; The discharge tray 52 between them; the sieve plate 202 and the extrusion plate 205 distributed up and down inside the granulation cylinder 2; the crushing structure 203 arranged on the top of the sieve plate 202; the cutting structure arranged at the bottom of the extrusion plate 205 206 ; the driving struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com