Manufacturing method of improved individual tray capable of preventing isolated abutment tooth from being broken and demolding method thereof

A production method and an improved technology, applied in the field of denture production, can solve the problems of isolated abutment tooth fracture, influence on cutting position, high cost, etc., and achieve the effect of simple production process, improved accuracy and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] This embodiment provides a method for making an improved individual tray to prevent isolated abutment teeth from breaking, including the following specific steps:

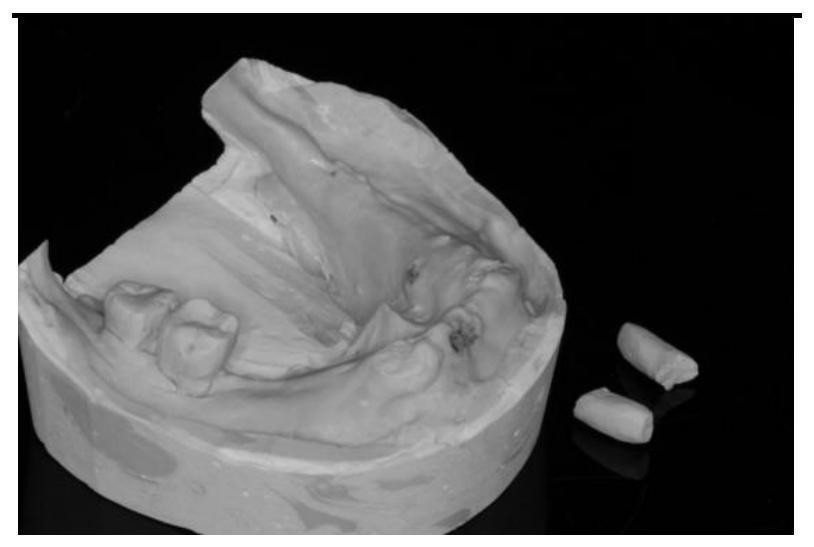

[0051] (1) select to exist the model of isolated abutment (two isolated abutments all fracture in the present invention), as figure 1 shown.

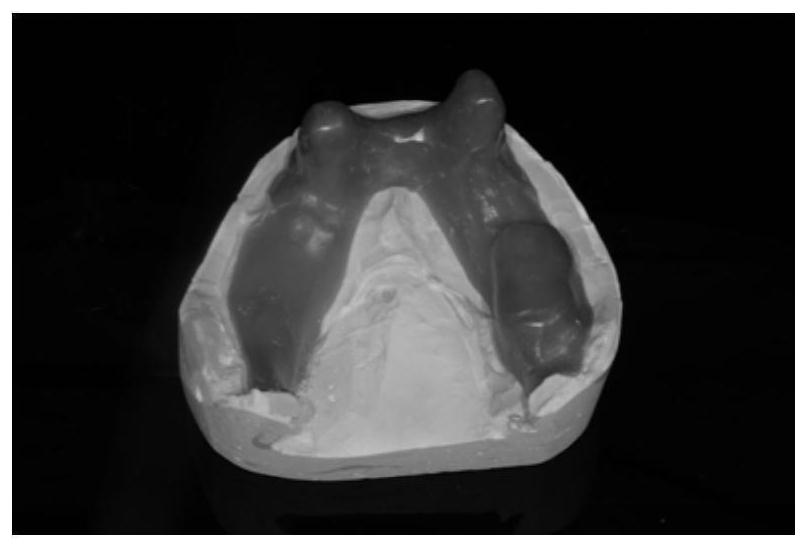

[0052] (2) First wrap the isolated abutment on the model with a 1.5mm wax sheet, then cover the entire model with the wax sheet and stop at 2mm from the reflexed line of the edge of the model, as in figure 2 Shown is a schematic diagram of the present invention covering the entire model with a wax sheet and ending at 2mm from the edge of the model on the folded line. It is the same as the traditional manufacturing method, and its effect is to reserve a space for placing materials when taking the model.

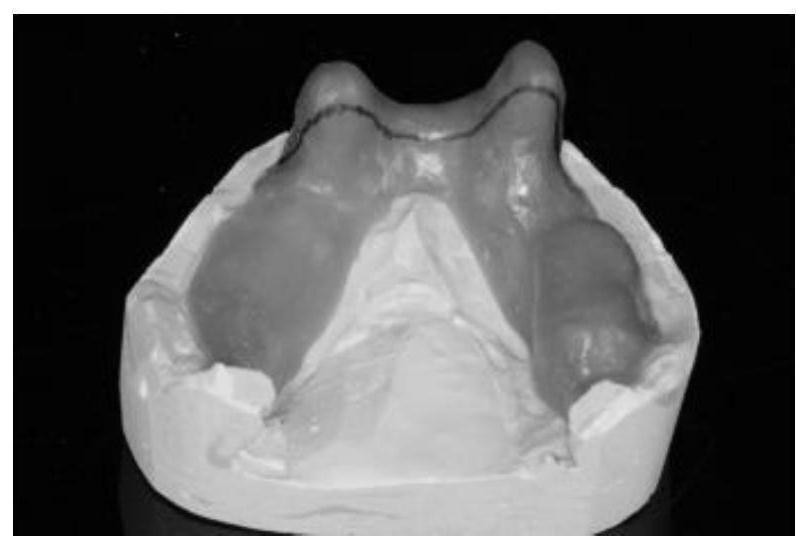

[0053] (3) Mark the highest point of the isolated abutment with a black marker, draw an arc along the mesial-distal direction of the isolated abutment through the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com