Continuous vacuum distillation crude magnesium refining and pull casting magnesium ingot device and technological process thereof

A vacuum and cast magnesium technology, applied in the field of magnesium smelting, can solve the problems of low production efficiency, complex refining process, non-continuous operation, etc., achieve high production efficiency, improve production efficiency, and reduce re-melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific examples.

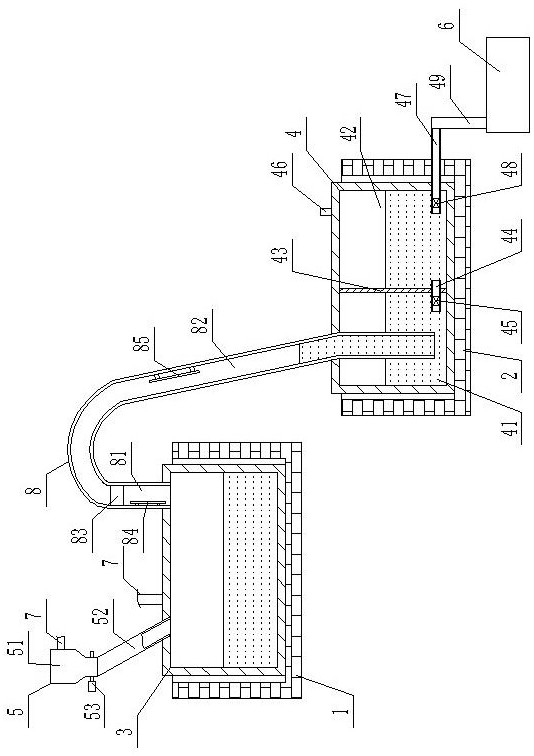

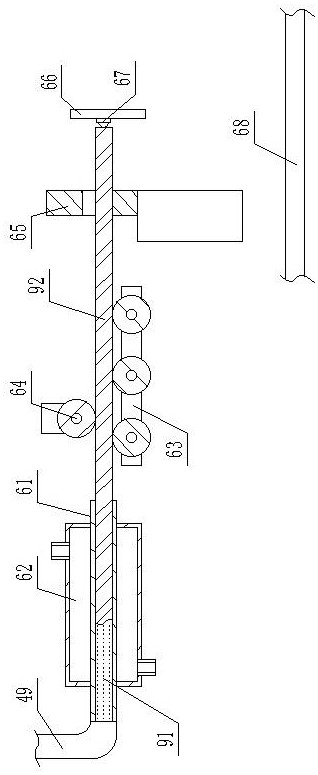

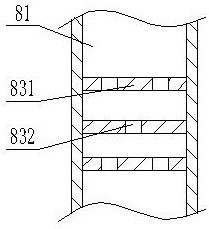

[0039] Continuous vacuum distillation crude magnesium refining, magnesium ingot drawing device, including: heating furnace A1, heating furnace B2, distillation crucible 3, heat preservation crucible 4, feeding device 5 and drawing casting device 6, the distillation crucible 3 is set in the heating In the furnace A1, the heat preservation crucible 4 is arranged in the heating furnace B2, and the inside of the heat preservation crucible 4 is divided into a heat preservation room 41 and a heat preservation second room 42 by a baffle plate 43, and the baffle plate 43 is provided with a communicating Pipe 44, the liquid valve A45 is arranged in the communication pipe 44;

[0040] The feeding device 5 includes: a feeding hopper 51 and a feeding pipe 52, the lower end of the feeding hopper 51 is provided with a discharge port, the discharge port is provided with a discharge valve 53,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com