Water-rich stratum open cut underground structure composite waterproof structure and construction method

A waterproof structure and underground structure technology, applied in underwater structures, infrastructure engineering, excavation, etc., can solve problems such as difficulty in completely preventing groundwater infiltration, failure of waterproof performance of the entire structure, and low tensile strength of waterproof concrete. Achieve the effect of improving waterproof reliability, high bonding strength, and high elastic recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

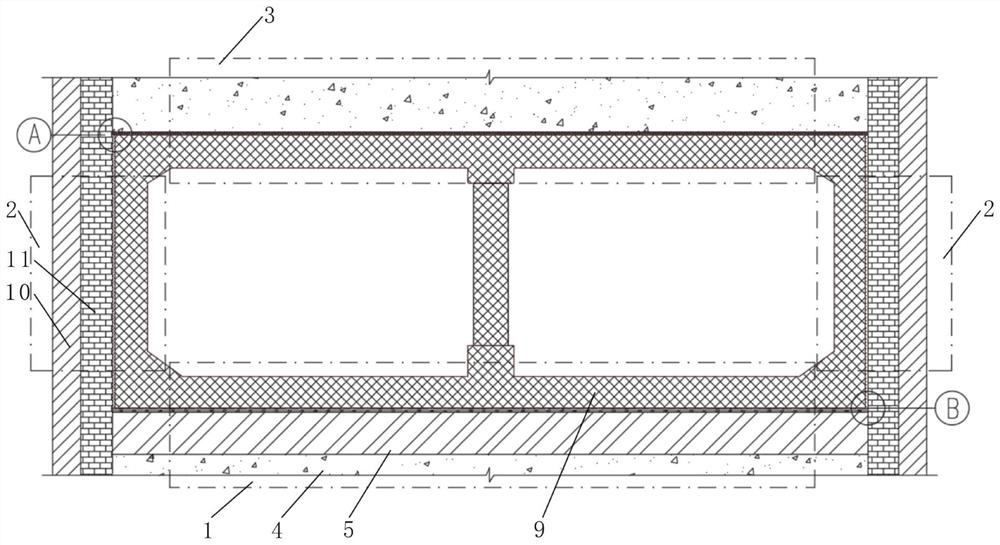

[0041] Such as figure 1 As shown, a composite waterproof structure of an open-cut underground structure in a water-rich stratum according to the present invention includes a bottom composite waterproof structure 1 , a side wall composite waterproof structure 2 , and a roof composite waterproof structure 3 that encloses a main structure 9 in the middle.

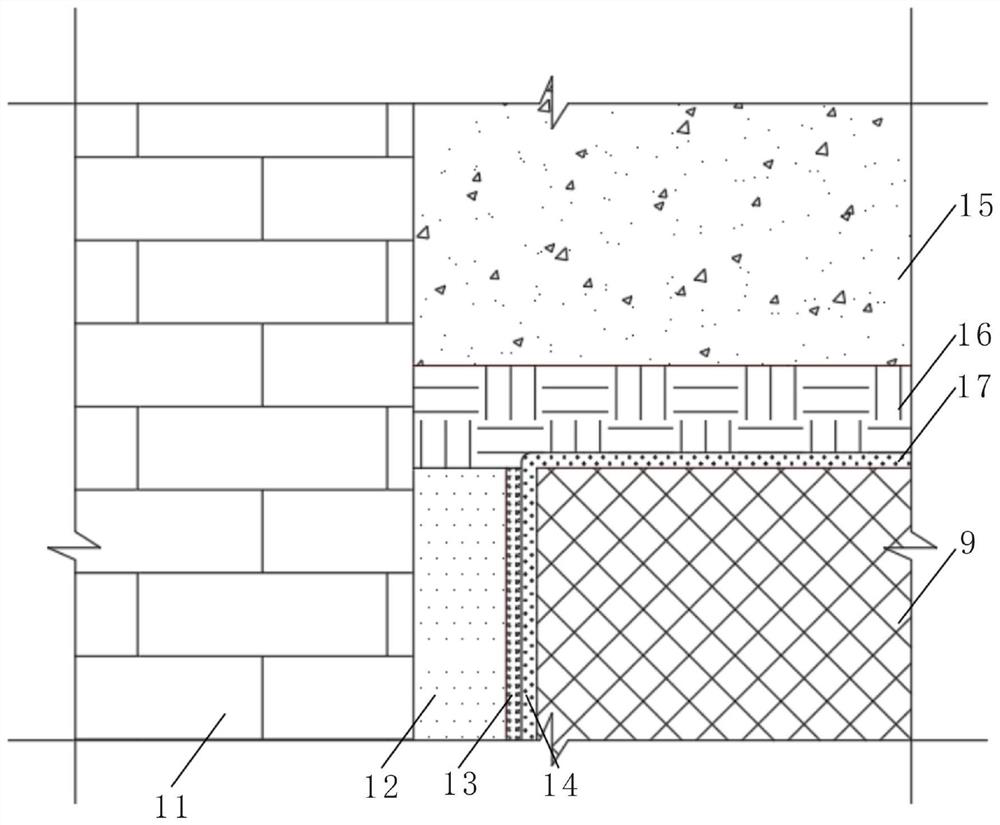

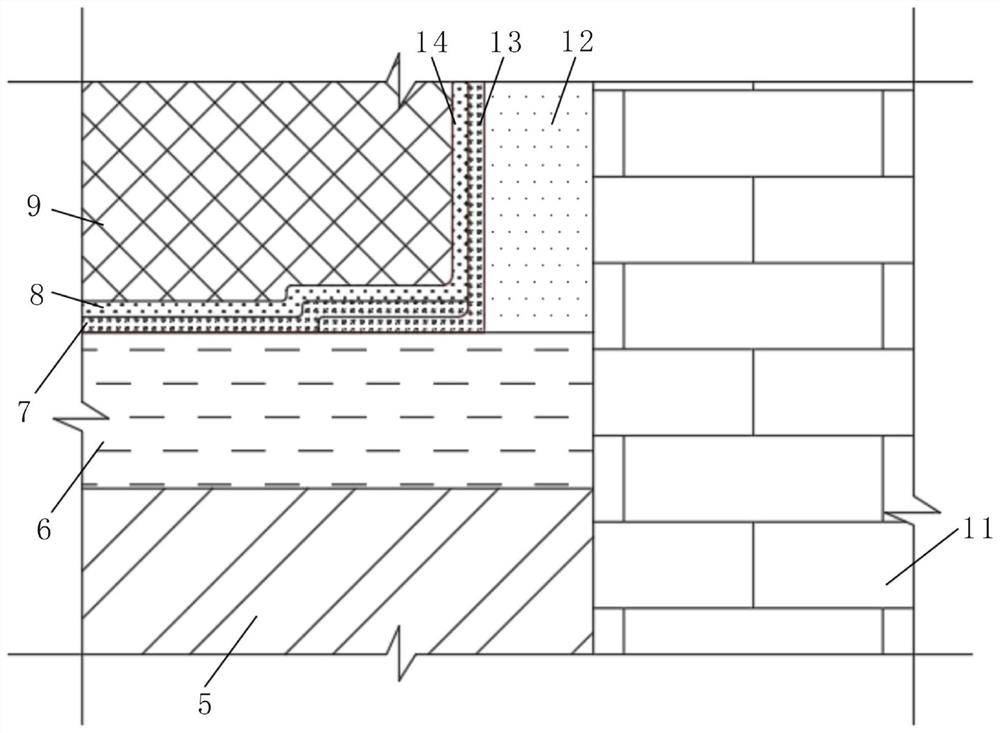

[0042] Among them, such as figure 1 , figure 2 , image 3As shown, the bottom plate composite waterproof structure 1 includes soil layer 4, cement mixing pile 5, concrete cushion 6, HDPE waterproof sheet 7, quick-setting waterproof coating 8 from bottom to top, and the main structure 9 is located in the quick-setting waterproof coating 1 The upper side of 8; the side wall composite waterproof structure 2 includes high-pressure rotary grouting pile 10, enclosure structure 11, base leveling layer 12, HDPE waterproof sheet 2 13, quick-setting waterproof coating 2 14 from outside to inside, and the main structure 9 is located ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com