Device for measuring inner diameter of through hole of coupling

A technology of inner diameter and laser ranging, which is applied in the field of devices for measuring the inner diameter of through holes of couplings, and devices for measuring the inner diameter of through holes of special threaded couplings, can solve the problems of irregular operation, difficult operation and low operation efficiency, etc. Achieve the effect of avoiding tediousness and errors, increasing accuracy and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below with examples. These examples are only descriptions of the best implementation modes of the present invention, and do not limit the content of the present invention in any way.

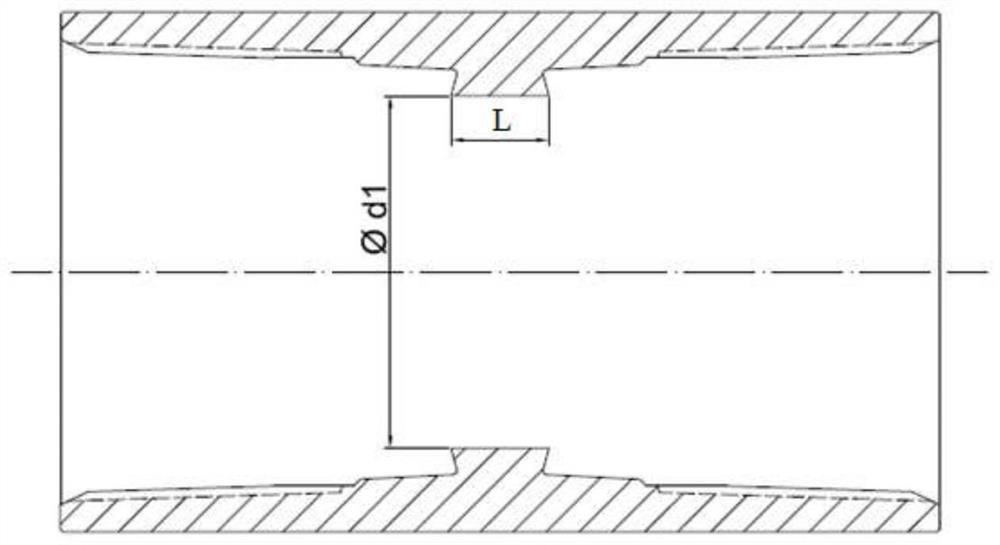

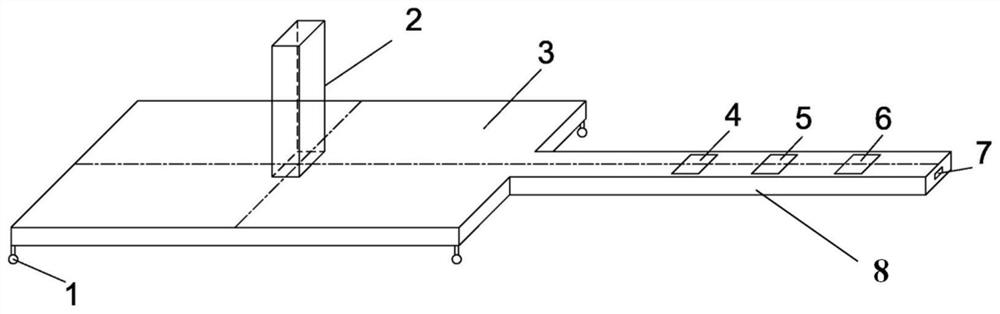

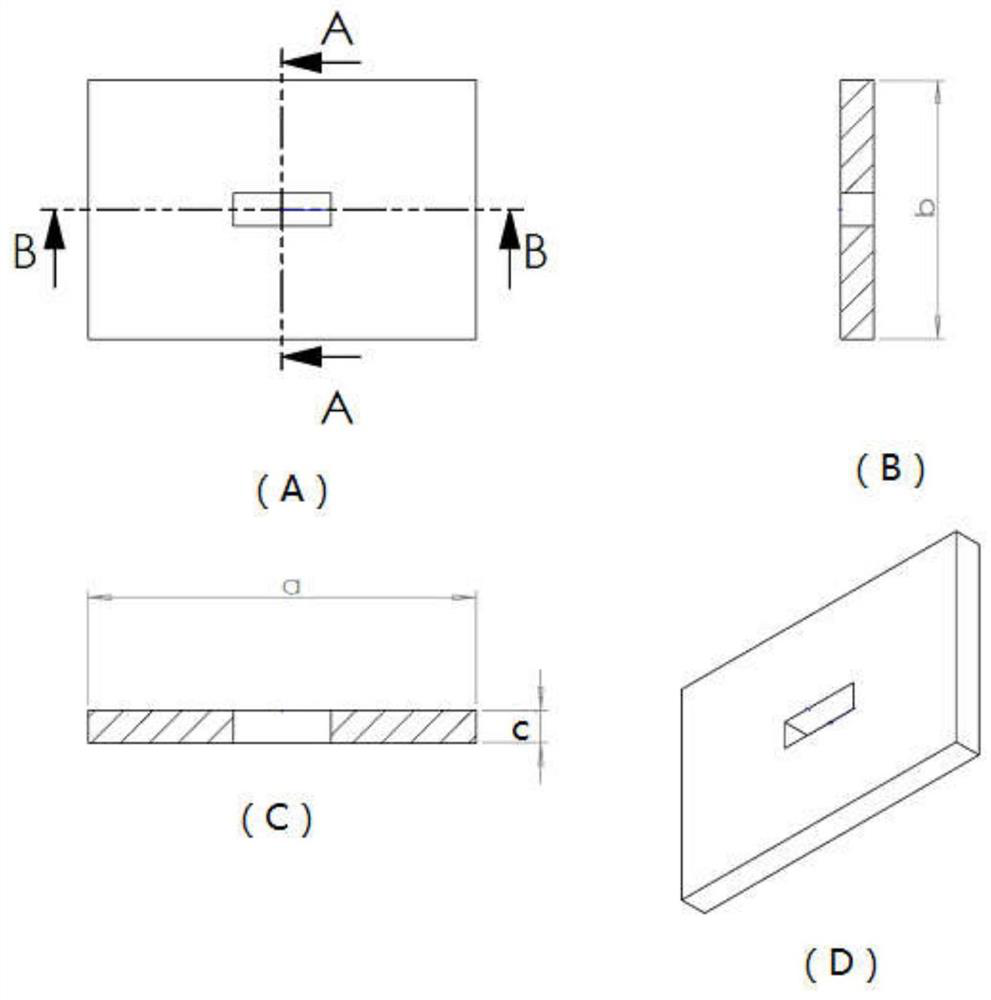

[0020] like figure 2 As shown, it shows a schematic structural view of the device for measuring the inner diameter of the collar through hole provided by the present invention. The device includes a laser ranging probe 2, a measuring bracket 3, a digital display screen 4, a "start" button 5, a reset " "reset" button 6, USB charging port 7, support rod 8, and may also include a measurement bracket contact 1, wherein the measurement bracket 3 and the support rod 8 are fixedly connected to form the device body. like image 3 As shown, a schematic view of the structure of the measuring bracket 3 is shown, which can be a rectangle, wherein A frame is a structural schematic view of the measuring bracket 3, B frame is a schematic cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com