Wear-resistant and repairable super-hydrophobic metal net and preparation method thereof

A metal mesh and super-hydrophobic technology, which is applied to the surface coating liquid device, pre-treated surface, coating, etc., can solve the problems of poor durability and irreparable surface wetting performance, and achieve good super-hydrophobic stability, The effect of excellent environmental stability and excellent friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

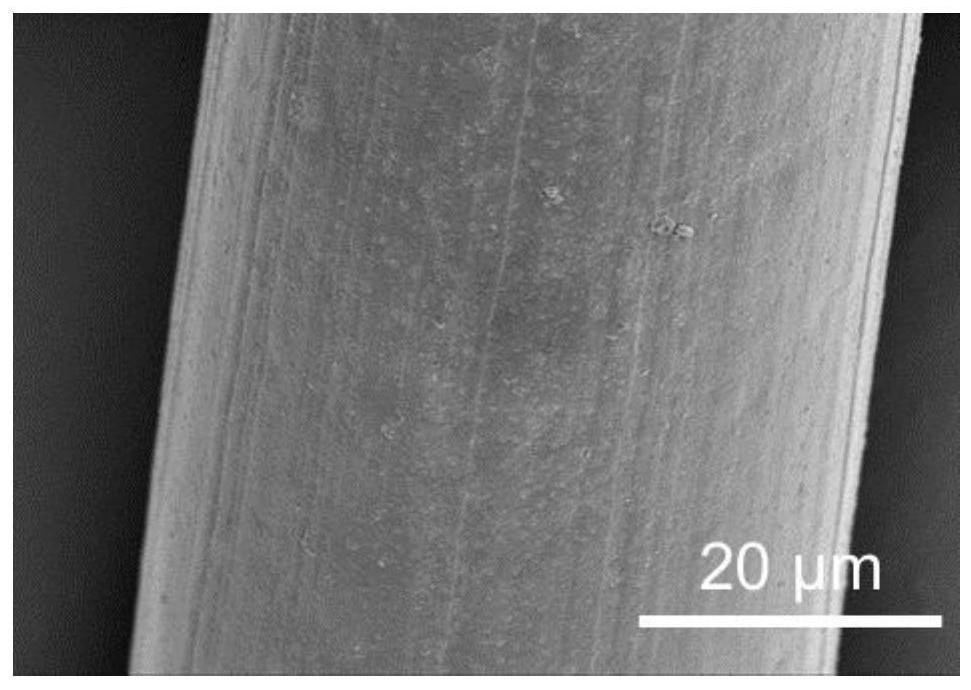

[0042] A preparation method of wear-resistant and repairable superhydrophobic stainless steel mesh, such as Figure 10 As shown in the flow chart, it includes the following steps:

[0043] (1) Repeated ultrasonic cleaning with ethanol and deionized water to remove the organic pollutants and dust attached to the surface of the stainless steel mesh with a mesh number of 200 mesh stainless steel mesh;

[0044] (2) Soak the cleaned stainless steel net in n-hexane solution of polydimethylsiloxane with a solid content of 10% wt (the mass ratio of polydimethylsiloxane to curing agent is 10:1) 3 to 5 minutes, then take it out, put it in an oven at 120°C to cure for 2 hours, and obtain a stainless steel mesh whose surface is coated with polydimethylsiloxane;

[0045] (3) Burn the stainless steel mesh coated with polydimethylsiloxane on the surface for 10 s with the outer flame of an alcohol lamp to obtain a wear-resistant and repairable super-hydrophobic / super-oleophilic stainless ste...

Embodiment 2

[0049] A method for preparing a wear-resistant and repairable superhydrophobic copper mesh, comprising the steps of:

[0050] (1) Repeated ultrasonic cleaning of the copper mesh with 200 meshes with ethanol and deionized water to remove organic pollutants and dust attached to the surface of the copper mesh;

[0051] (2) Soak the cleaned copper grid in a n-hexane solution of polydimethylsiloxane with a solid content of 5% wt (the mass ratio of polydimethylsiloxane to curing agent is 10:1) 3 to 5 minutes, then take it out, put it in an oven at 80°C to cure for 2 hours, and obtain a copper mesh coated with polydimethylsiloxane on the surface;

[0052] (3) Burn the copper mesh coated with polydimethylsiloxane on the surface for 10 s with the outer flame of an alcohol lamp to obtain a wear-resistant and repairable superhydrophobic / superoleophilic copper mesh.

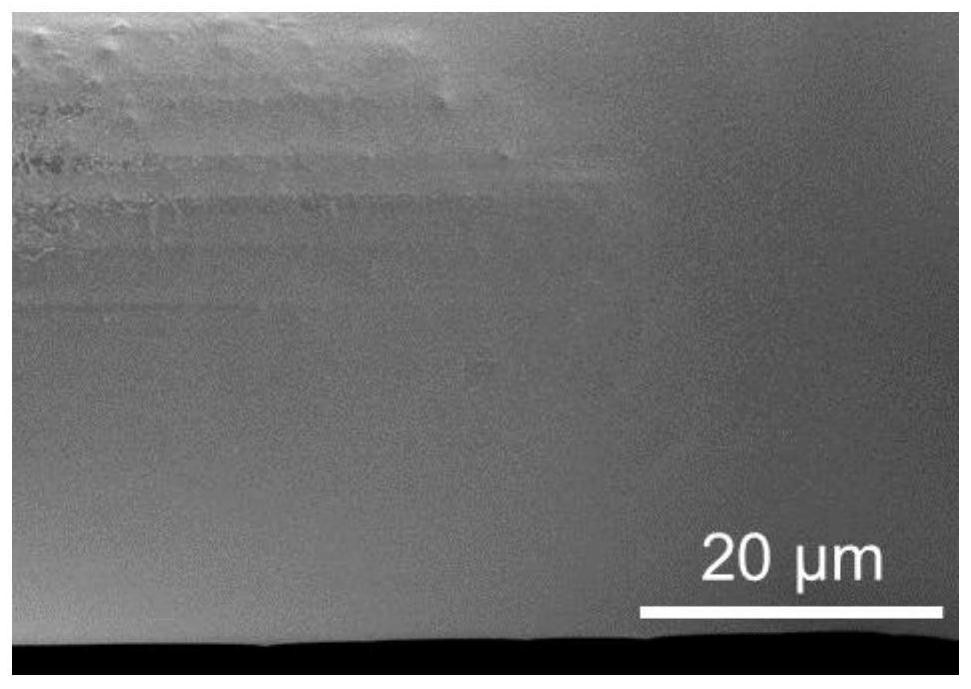

[0053] The superhydrophobic / superoleophilic copper mesh prepared in this example was analyzed under a scanning electron m...

Embodiment 3

[0056] A method for preparing a wear-resistant and repairable superhydrophobic stainless steel mesh, comprising the steps of:

[0057] (1) Repeated ultrasonic cleaning with ethanol and deionized water to remove the organic pollutants and dust attached to the surface of the stainless steel mesh with a mesh number of 200 mesh stainless steel mesh;

[0058] (2) Soak the cleaned stainless steel net in n-hexane solution of polydimethylsiloxane with a solid content of 15%wt (the mass ratio of polydimethylsiloxane to curing agent is 10:1) 3 to 5 minutes, then take it out, put it in an oven at 105°C to cure for 2 hours, and obtain a stainless steel mesh coated with polydimethylsiloxane on the surface;

[0059] (3) Burn the stainless steel mesh coated with polydimethylsiloxane on the surface for 10 s with the outer flame of an alcohol lamp to obtain a wear-resistant and repairable super-hydrophobic / super-oleophilic stainless steel mesh.

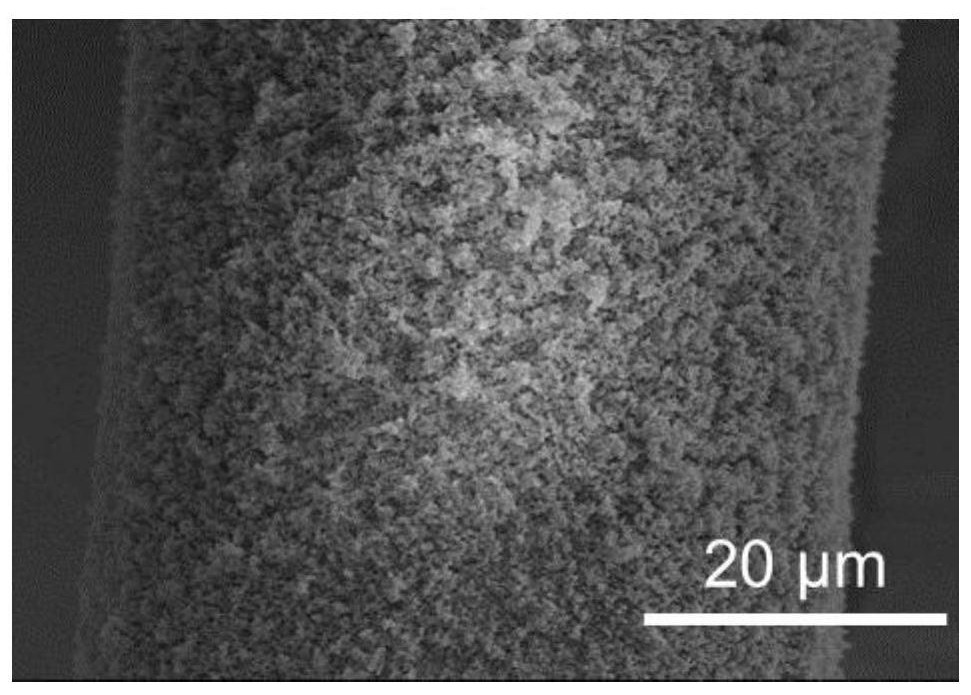

[0060] The superhydrophobic / superoleophilic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com