Plain carbon steel wire rod for wire drawing and production process

A production process, the technology of ordinary carbon steel, applied in the direction of metal rolling, etc., can solve problems such as head and tail fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

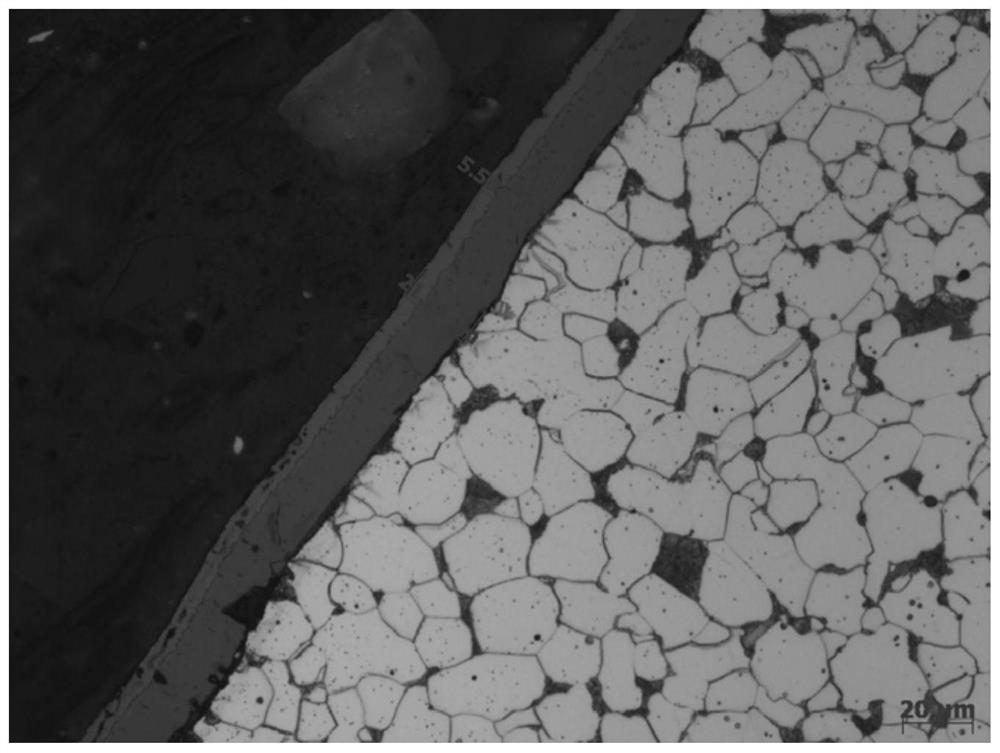

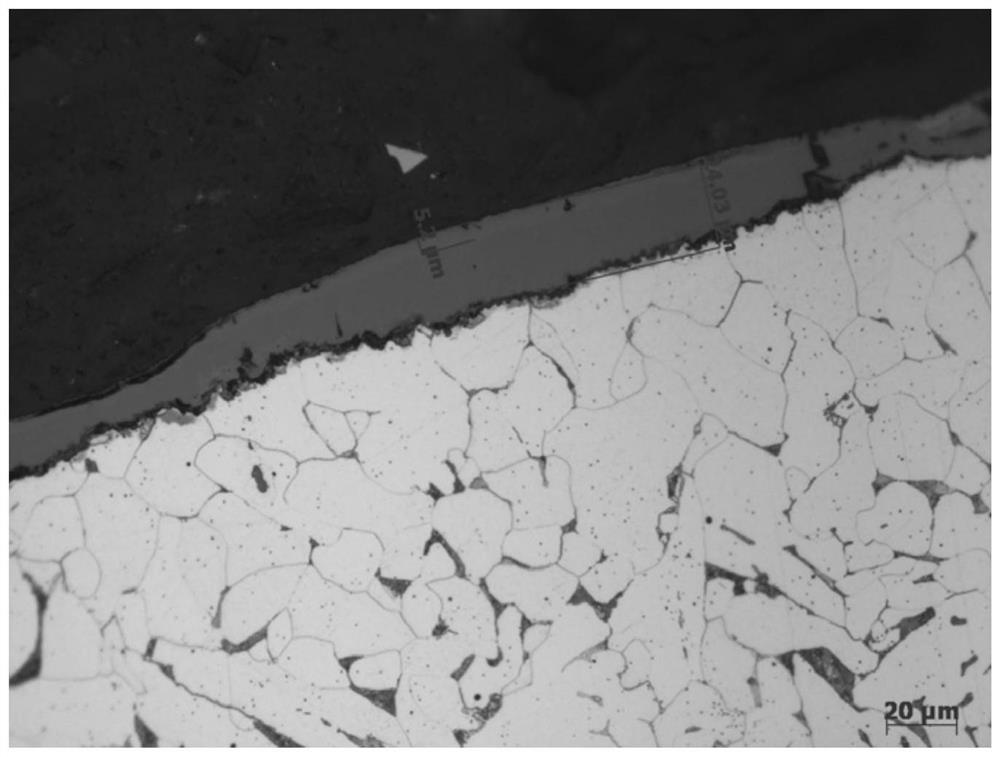

Image

Examples

Embodiment 1

[0022] Production specification: Ф6.5mm wire rod

[0023] Steel grade: Q235L

[0024] Rolling mills in use: Stands 1 to 26

[0025] Production furnace number: 2102892

[0026] Chemical composition: C: 0.14%; Si: 0.18%; Mn: 0.43%; P: 0.022%; S: 0.012%; N: 0.0035%.

[0027] Heating in a 150 billet heating furnace to a rolling start temperature of 1005°C, entering the rough rolling unit for rolling in the first to sixth stands, 1# cutting the head and tail, and then entering the middle rolling mill for rolling in the seventh to 12th stands, 2# After cutting the head, the shearing machine enters the 4 pre-finishing rolling mills for rolling, opens the 1# water tank, controls the temperature of the rolled piece to enter the finishing rolling mill at 996°C, and the 3# flying shear head enters the 10-stand finishing rolling mill and rolls it into wire rod , turn on the 2# water tank, control the spinning temperature to 1038°C, the speed of the air-cooling line roller table is 0.40...

Embodiment 2

[0030] Production specification: Ф6.5mm wire rod

[0031] Steel grade: Q235L

[0032] Rolling mills in use: Stands 1 to 26

[0033] Production furnace number: 1102840

[0034] Chemical composition: C: 0.17%; Si: 0.19%; Mn: 0.43%; P: 0.024%; S: 0.017%; N: 0.0041%.

[0035]Heating in a 150 billet heating furnace to a rolling start temperature of 1022°C, entering the rough rolling unit for rolling at the first to sixth stands, 1# cutting the head and tail, and then entering the middle rolling mill for rolling at the seventh to 12th stands, 2# After cutting the head of the shearing machine, enter the 4 pre-finishing rolling mills for rolling, open the 1# water tank, control the temperature of the rolled piece entering the finishing rolling mill at 1005°C, and then enter the 10-stand rolling mill of the 3# fly-shearing mill to make wire rods , turn on the 2# water tank, control the spinning temperature at 1035°C, the speed of the air-cooling line roller table is 0.40m / s, the coi...

Embodiment 3

[0038] Production specification: Ф6.5mm wire rod

[0039] Steel grade: Q235L

[0040] Rolling mills in use: Stands 1 to 26

[0041] Production furnace number: 2102397

[0042] Chemical composition: C: 0.15%; Si: 0.15%; Mn: 0.46%; P: 0.026%; S: 0.015%; N: 0.0040%.

[0043] Heating in a 150 billet heating furnace to the rolling start temperature of 1035°C, entering the rough rolling mill stand 1-6 for rolling, 1# cutting the head and tail, entering the intermediate rolling mill stand 7-12 for rolling, 2# After cutting the head, the shearing machine enters the 4 pre-finishing rolling mills for rolling, opens the 1# water tank, controls the temperature of the rolled piece to enter the finishing rolling mill at 1006°C, and the 3# flying shear head enters the 10-stand finishing rolling mill and rolls it into wire rod , turn on the 2# water tank, control the spinning temperature to 1040°C, the speed of the air-cooled line roller table is 0.40m / s, collect the wire rod on the reel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com