Pouring system and method for producing rollers

A pouring system and pouring method technology, applied in the field of compressors, can solve problems such as uneven hardness of rollers, excessive thermal expansion coefficient, etc., and achieve the effects of low connection strength, improved yield, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment describes in detail the pouring system used for producing rollers of the present invention.

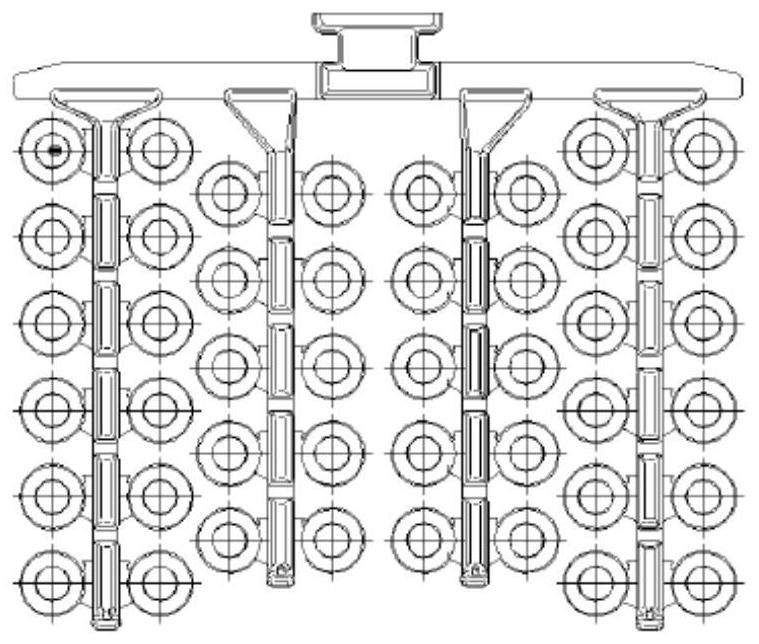

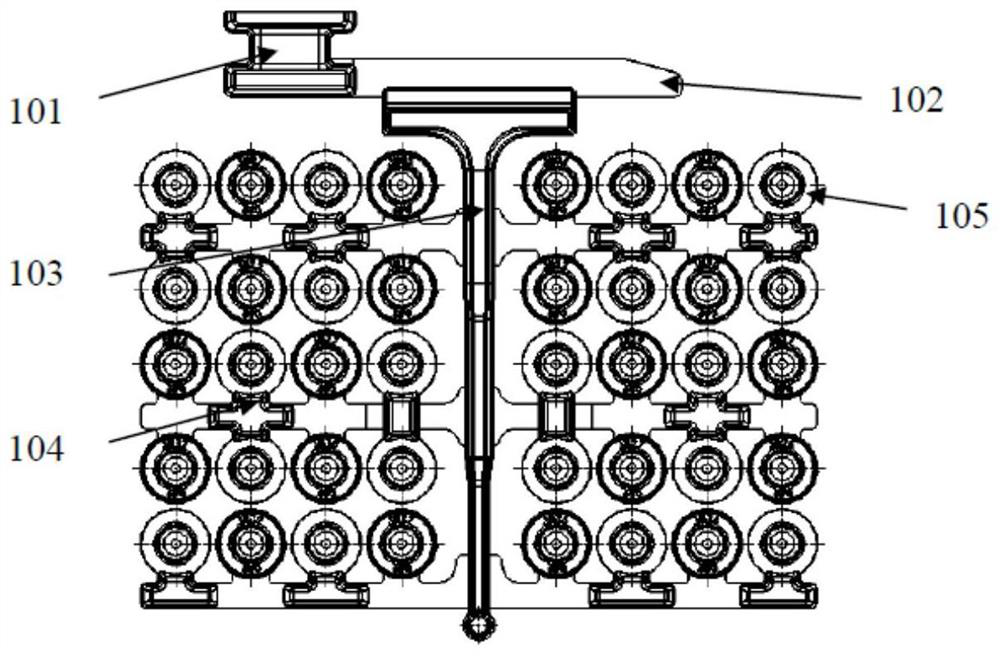

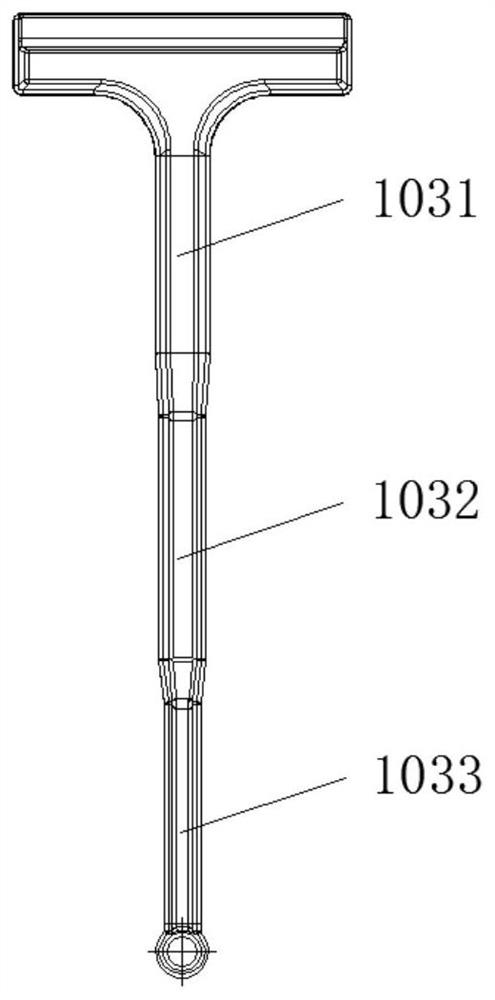

[0038] This embodiment is used for the gating system of producing roller, comprises sprue cup 101, runner 102, sprue 103, a plurality of inrunners 104 and a plurality of roller molds 105, as figure 2 shown. Preferably, the sprue cup 101 is communicated with the runner 102, the sprue 103 is communicated with the runner 102, a plurality of inrunners 104 are distributed on the side of the sprue 103 and communicated with the sprue 103, and the plurality of runners The sub-mold 105 is distributed on the upper side and / or the lower side of the inner runner 104 and communicates with the inner runner 104, such as figure 2 shown. More preferably, the cross-sectional area of the sprue 103 gradually decreases from one end close to the sprue 102 to an end far away from the sprue 102, and the inner sprue 104 connected to different positions of the sprue 103 is simultan...

Embodiment 2

[0047] This embodiment describes in detail the pouring method for producing rollers of the present invention.

[0048] The pouring method that this embodiment is used for producing roller is to utilize any technical scheme in embodiment 1 to be used for the pouring system of producing roller to finish. Preferably, the pouring method used to produce the roller in this embodiment includes the following steps:

[0049] S1: pour molten iron into the sprue cup 101 .

[0050] S2: The molten iron in the sprue cup 101 flows into the sprue 103 through the runner 102 .

[0051] S3: The molten iron in the sprue 103 is distributed to the ingate 104.

[0052] S4: The molten iron in the runner 104 flows into the roller mold 105, and the runner 104 near the end of the runner 102 and the runner 104 at the end far away from the runner 102 complete the filling of the roller mold 105 at the same time .

[0053] The pouring method used in this embodiment to produce rollers is realized by util...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com